Adiabatically following stark chirp light beam shaper

A technology of beam shaping and heat insulation, which is applied in optics, lasers, optical components, etc., can solve the problems of not providing practical devices, etc., and achieve the effects of amplification and shaping, high diffraction efficiency, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

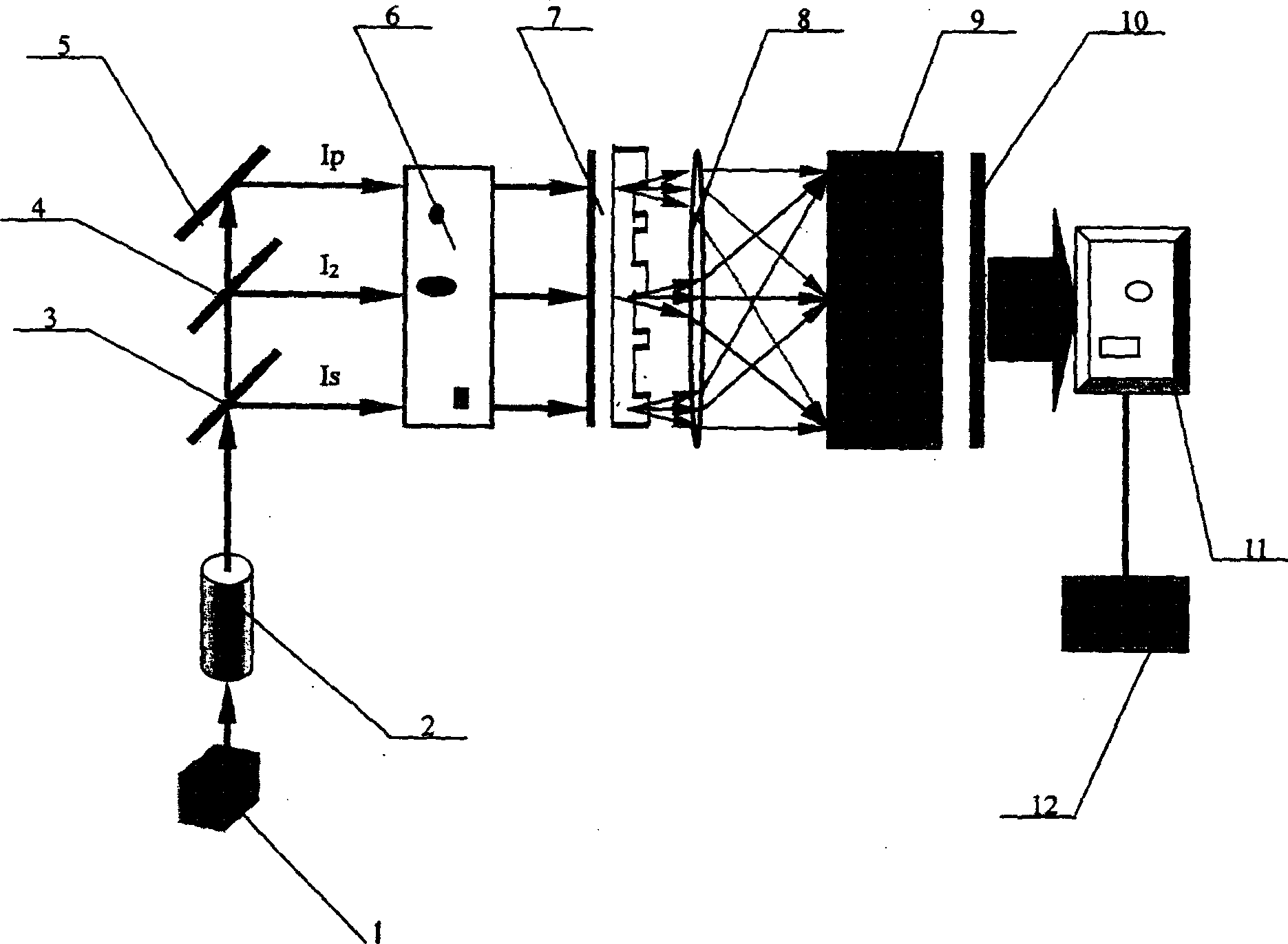

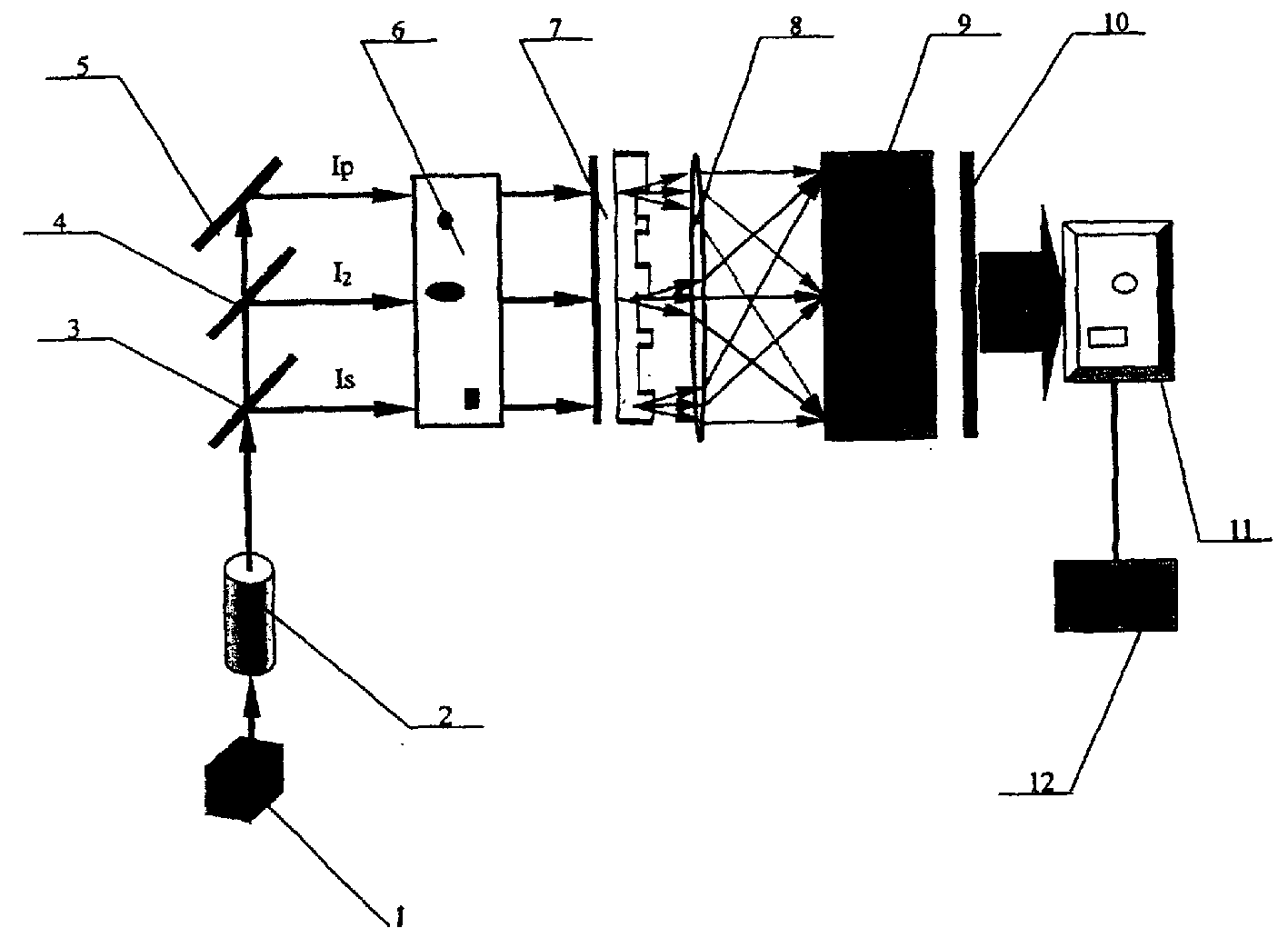

[0041] see first figure 1 , figure 1 It is a schematic structural diagram of the best embodiment of the adiabatic following Stark chirp beam shaping device of the present invention. It can be seen from the figure that the adiabatic following Stark chirping beam shaping device of the present invention includes the most core element as the binary optical element 7 , the electro-optic modulator 11, the pulse delay adjuster 6 is placed before the binary optical element 7, and before the pulse delay adjuster 6 is the anti-reflection polarizer 3, the semi-transparent and half-reflective polarizer 4 and the polarization total reflection multiplier The frequency crystal 5 is placed before the polarized total reflection frequency doubling crystal 5 and is the semi-transparent and semi-reflective polarizer 4, and before the semi-transparent and semi-reflective polarizer 4 is the anti-reflection polarizer 3, and before the anti-reflection polarizer 3 There is a laser light source 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com