Floating leakage blocking process

A drifter and leak repair technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of replacing new water pipes or digging soil to repair leaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

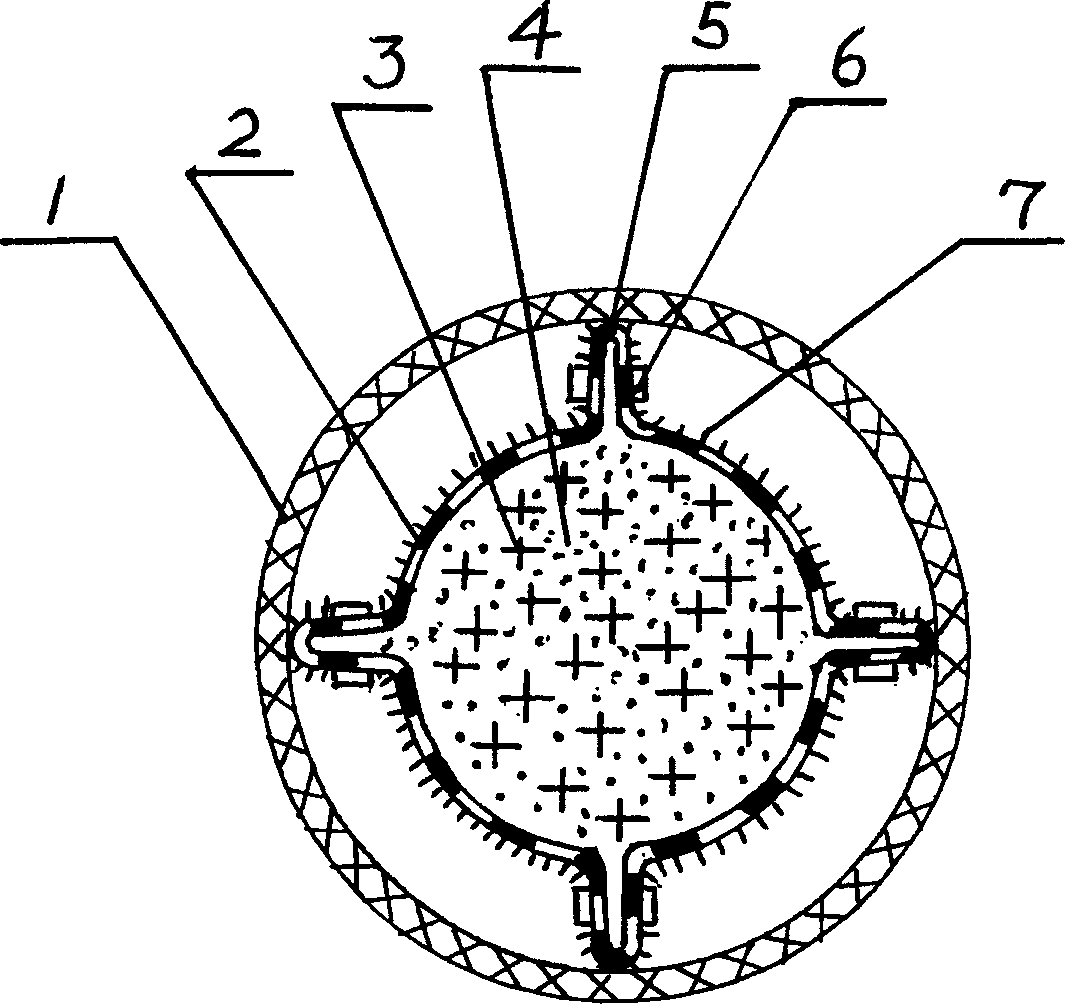

[0009] figure 1 It is a schematic diagram of a spherical drifter that can trap leaks for a long time. 1 in the figure is the shell that will gradually soften and dissolve after encountering water, such as multi-layer paper paste. 2 is a soft and hooked net in the shell, such as nylon net, 3 indicates the fiber filaments in the net (indicated by "+" in the figure), and 4 indicates a viscose containing a curing agent, such as silicone mucus (Fig. Indicated by small dots), the viscose is before the drifter is put into the water pipe, after passing through the housing 1 and the net 2 with the injection syringe, the liquid viscose is injected into the net and mixed with the fiber filament 3 (the following The viscose glue in the embodiment also adopts this method to inject it into the location), and the above-mentioned net 2, fiber filament 3 and viscose glue 4 are combined into a leak-repelling material with anti-shedding function. The specific gravity of the leak trap should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com