Floor tile made of oil field sludge and its production process

A production method and technology for oilfield sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The curing strength does not meet the requirements of building bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

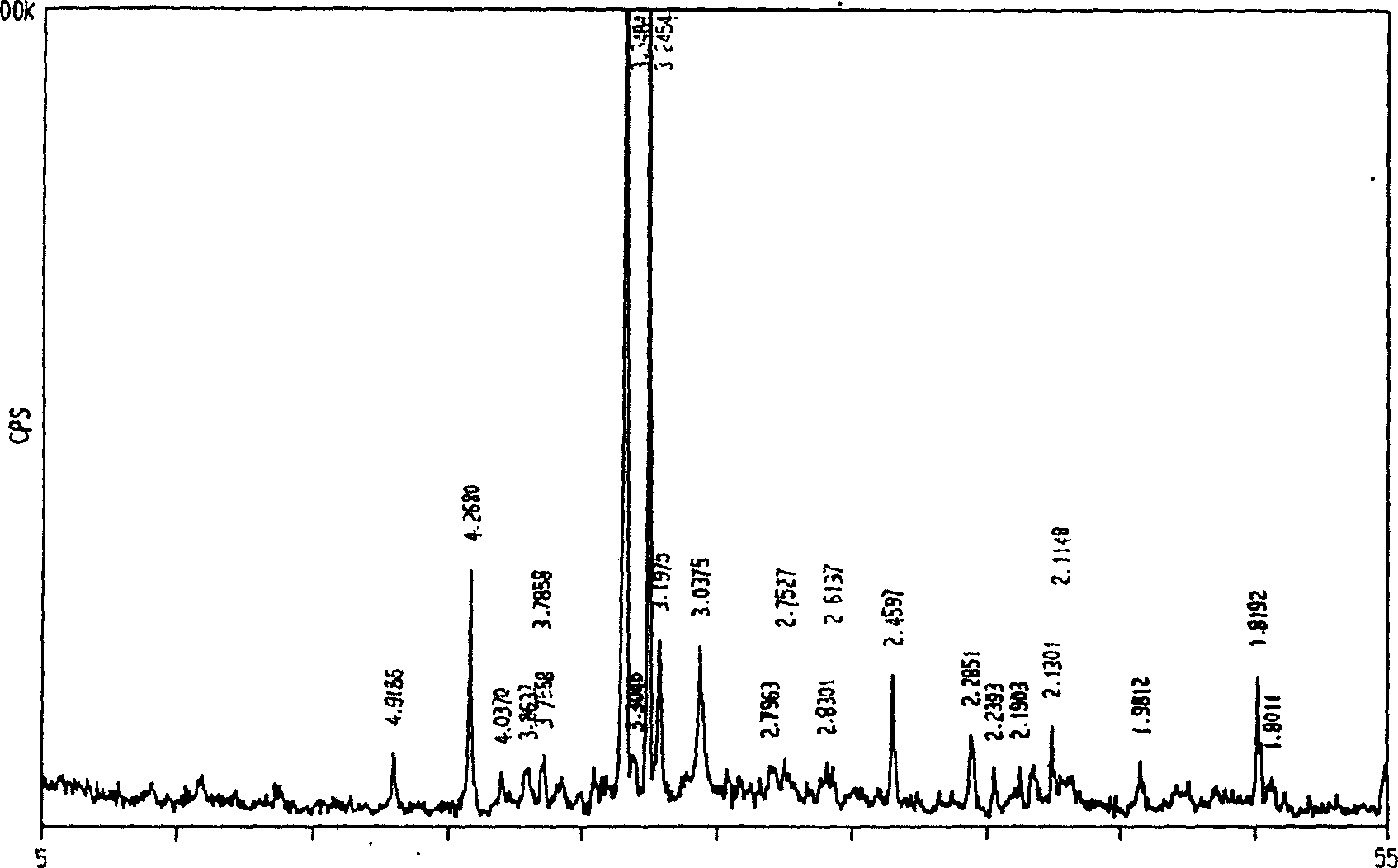

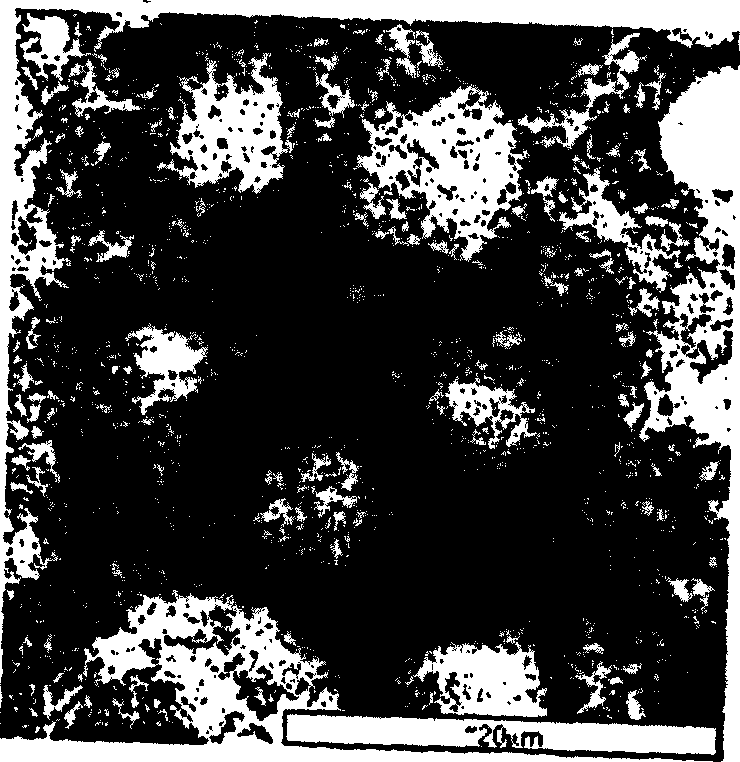

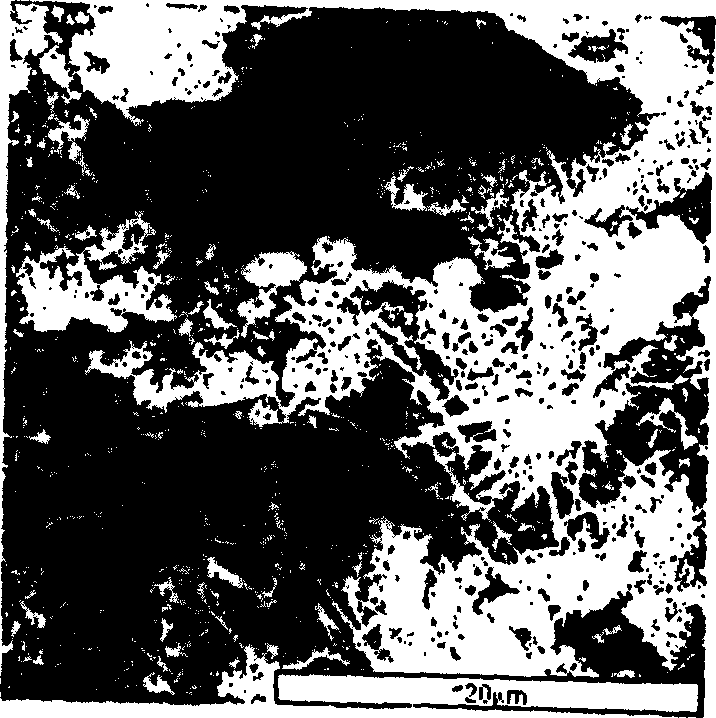

Image

Examples

Embodiment 1

[0063] The ratio of raw materials in this embodiment is 30% of oilfield sludge, 40% of river sand, 26% of cement, and 4% of curing agent.

[0064] Wherein, the curing agent is mixed with the raw materials in the following weight ratio:

[0065] Sulfoaluminate: 22% Calcium Stearate: 5%

[0066] Calcium Chloride: 20% Calcium Acetate: 0

[0067] Fluorite: 0 Gelatin: 5%

[0069] Acrylic resin 0

[0070] Core material: 10%

[0071] CaO

[0072] The production method is:

[0073] a) Colored cement is used for the color surface, and it is fully mixed with white gravel at a ratio of 1:2.5, and water is added to mix evenly according to the water-cement ratio of 0.5 to make a slurry; inject the slurry into the mold with a thickness of 1-2cm, and place it for half an hour ;

[0074] b) Mix the above-mentioned oilfield sludge, river sand, cement, fly ash, and curing agent evenly, inject it into the above-mentioned mold, vibrate on the vibrat...

Embodiment 2

[0079] The raw material ratio of the matrix in this embodiment is 40% of oilfield sludge, 20% of river sand, 20% of cement, 19% of fly ash, and 2% of curing agent.

[0080] Wherein, the curing agent is mixed with the raw materials in the following weight ratio:

[0081] Sulfoaluminate: 15% Calcium Stearate: 2%

[0082] Calcium Chloride: 10% Calcium Acetate: 15%

[0083] Fluorite: 10% Gelatin: 9%

[0085] Acrylic 4%

[0086] The production method is the same as in Example 1, and the floor tiles are made.

[0087] The performance test results are: the average compressive strength is 22.28, the water absorption rate is 7.34%, and the bulk density is 1.96g / cm 3 . Its mechanical properties can still meet the relevant national standards. Other properties are substantially the same as in Example 1.

Embodiment 3

[0089] The ratio of raw materials in this embodiment is 55% of oilfield sludge, 20% of river sand, 18% of cement, and 7% of curing agent.

[0090] Wherein, the proportioning of curing agent is:

[0091] Sulfoaluminate: 20% Calcium Stearate: 5%

[0092] Calcium Chloride: 15% Calcium Acetate: 10%

[0093] Fluorite: 0 Gelatin: 5%

[0095] Acrylic resin 0 Monoethylene glycol 5%

[0096] Sucrose 5%

[0097] Core material: 10%

[0098] Wherein the core material is made up of the following raw materials in weight percentage:

[0099] CaO

MgO

Fe 2 o 3

SiO 2

Al 2 o 3

Al 2 (SO 4 ) 4

Na 2 CO 3

FeSO 4

MgSO 4

5

5

6

15

12

20

20

7

10

[0100] The production method is the same as in Example 1, and floor tiles are obtained.

[0101] The performance test results are: the average compressive strength is 28.28, the water absorption rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com