Method of denitrification dephosphorization function of batch type operation reinforced membrane bioreactor

A bioreactor and operating mode technology, applied in the field of environmental engineering, can solve problems such as poor effluent quality, high energy consumption, difficult operation and control, etc., and achieve the effect of strong nitrogen and phosphorus removal capabilities, simple process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

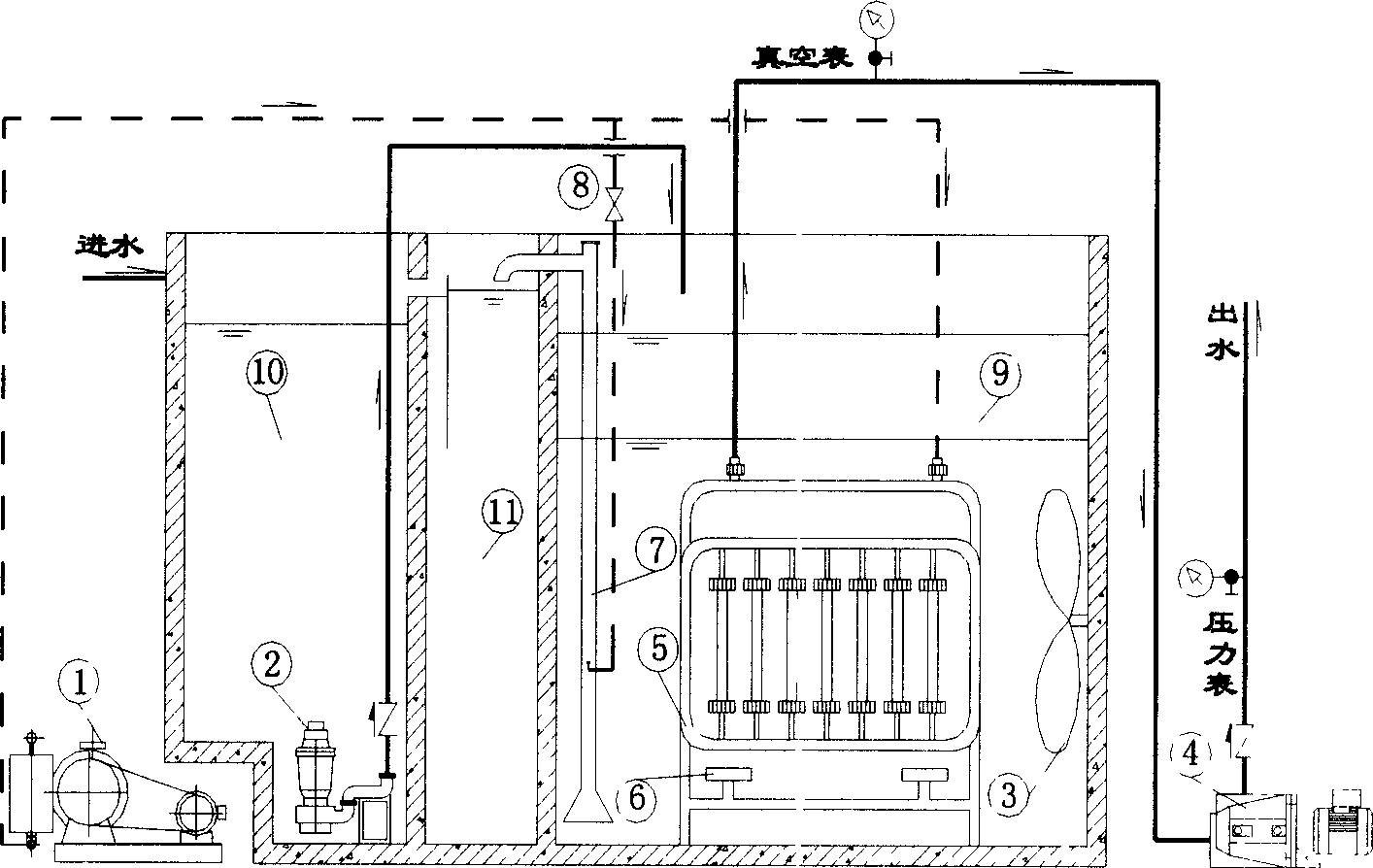

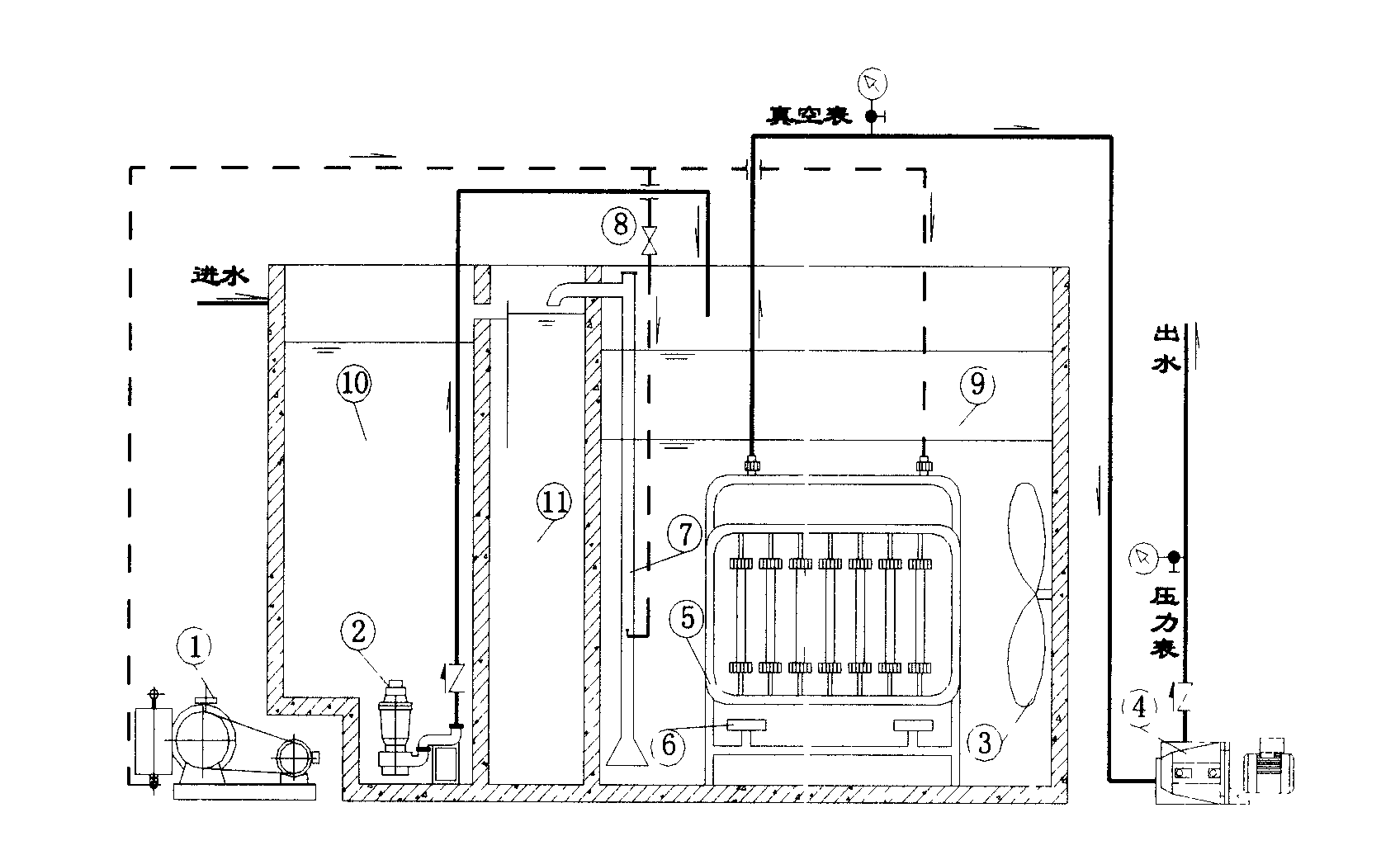

[0016] The C / N ratio in domestic sewage is usually above 10:1. At this time, the time relay is set to switch every hour. If the influent C / N ratio is lower than 10:1, the time of the aerobic stage in the cycle can be extended to strengthen nitrification; at the same time, the water output in the aerobic stage can be increased to increase the short-term time of the anoxic / anaerobic stage The amount of organic carbon source entering the reactor strengthens the denitrification effect.

[0017] The process runs in cycles, and each cycle is divided into two phases, namely the aerobic phase and the anoxic / anaerobic phase. The air blower (1) and the suction pump (4) start synchronously. At this stage, only water is discharged, and no water is taken in. The water level of the reaction tank (9) drops, which is an aerobic stage. After 1 hour, controlled by the time relay, the air blower (1) and the suction pump (4) stop running, and at the same time, the lifting pump (2) and the mixer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com