Heat Protector

A thermal protector and heating resistor technology, applied in thermal switches, thermal switch parts, contacts, etc., can solve the problem of inability to flow heating current, insufficient electrical contact stability between bimetal b and thermistor g, etc. problems, to achieve the effect of improving electrical contact stability, stable working characteristics, and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

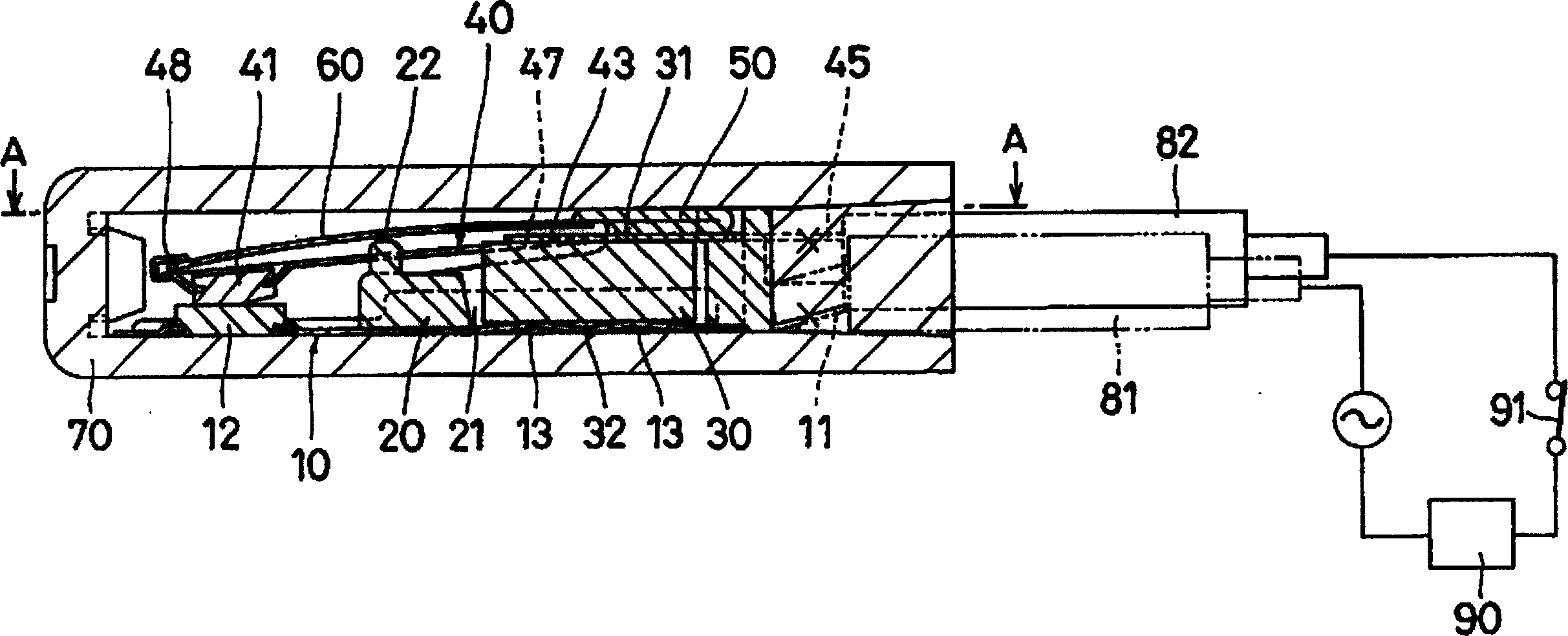

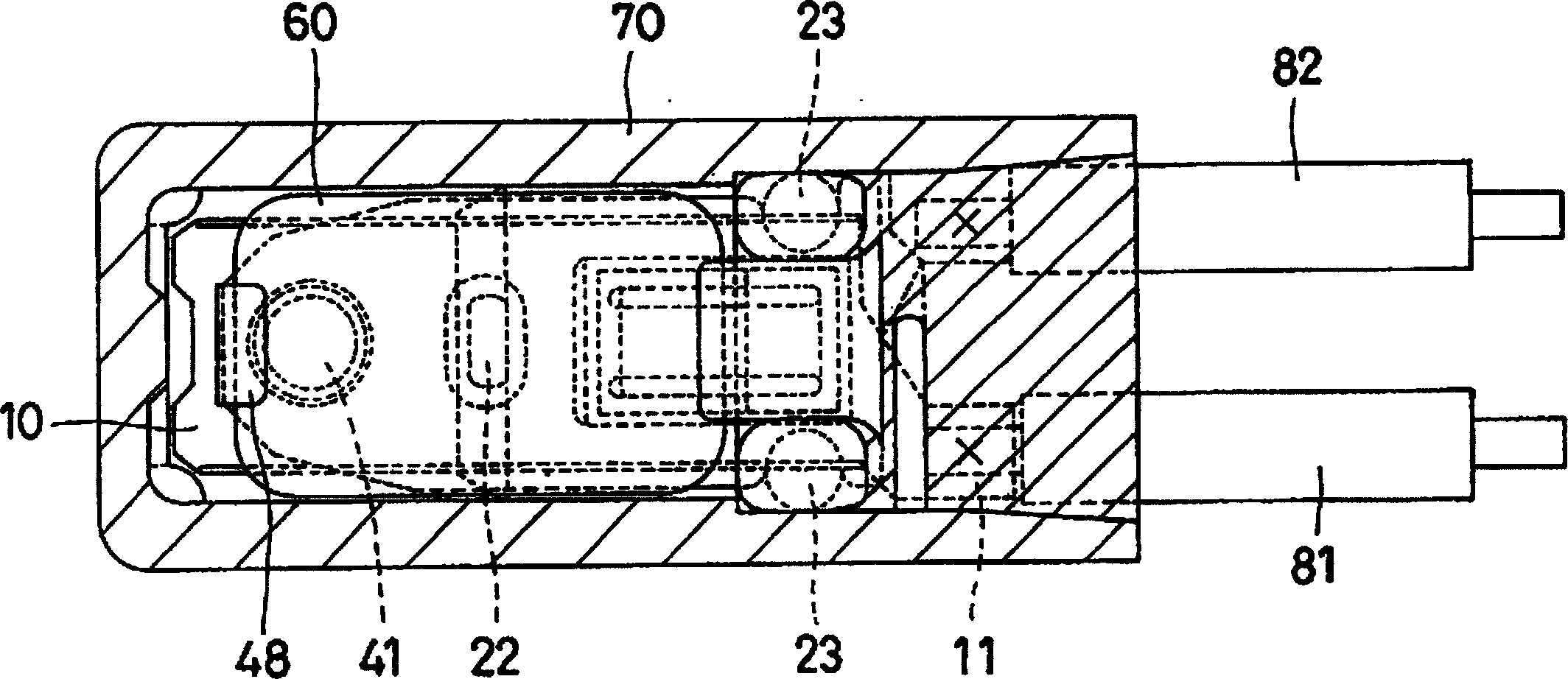

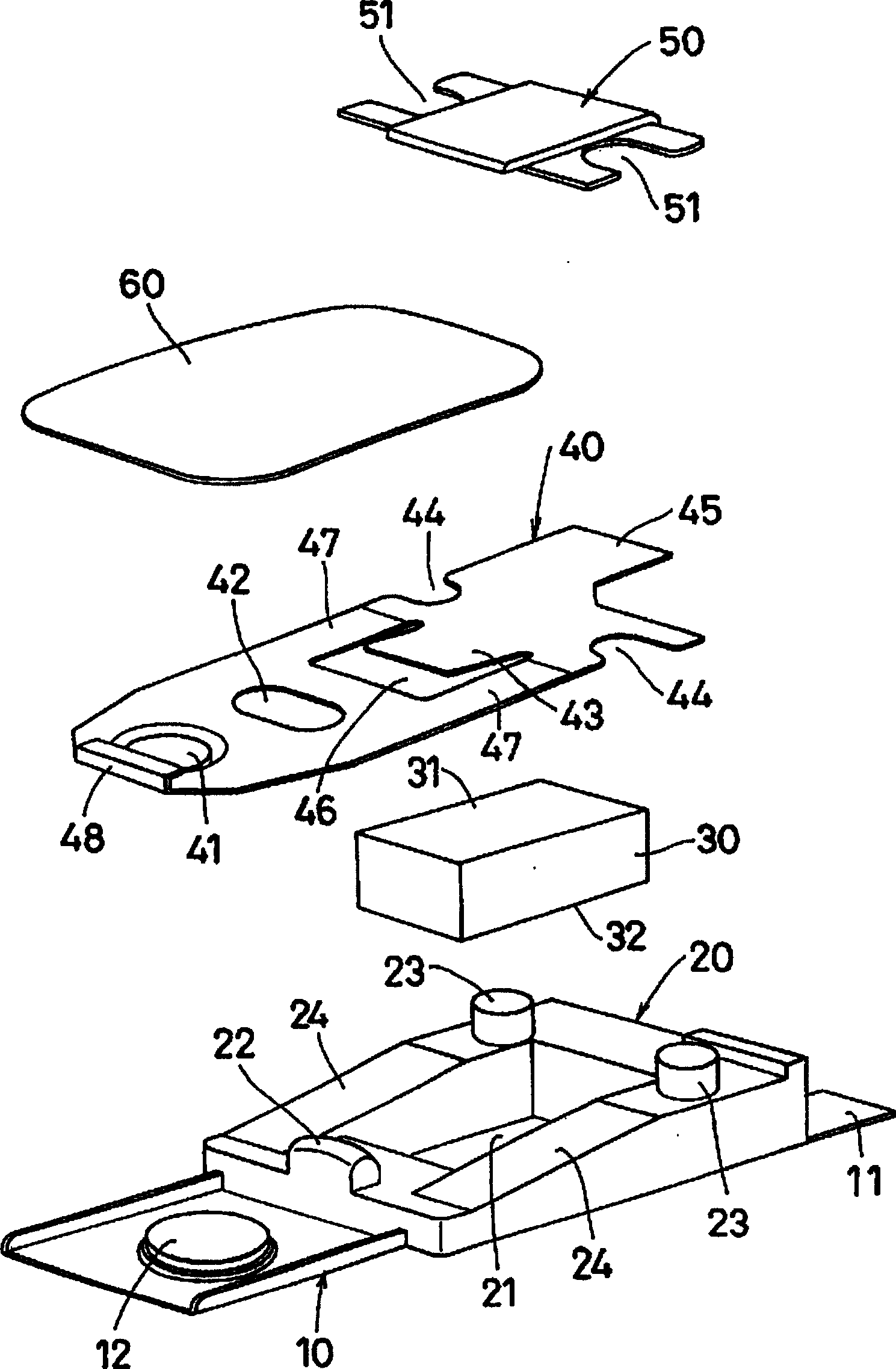

[0040] figure 1 is a longitudinal sectional view of a thermal protector structure according to the present invention, figure 2 yes figure 1 Sectional view taken along A-A, image 3 is a cross-sectional view of a thermal protector according to the present invention.

[0041] In these figures, a fixed plate 10 made of an elastic metal plate is formed with a terminal 11 for connection to the outside at its rear end, and a fixed contact 12 is arranged at its front end.

[0042] On the fixed plate 10, a support block 20 formed of an electrically insulating resin material is fixedly provided. The support block 20 is formed with a square hole 21 through its central portion, which accommodates a rectangular heating resistor consisting of a PTC element, such as image 3 shown. In addition, the support block 20 is formed with a protrusion 22 at the center of the upper surface of the front end thereof, and posts 23 are formed at both sides of the upper surface of the rear end the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com