Thermal state method for restoring branch pipe orifice of blast furnace bustle pipe

A repair method and supporting technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems such as affecting output and affecting furnace conditions, and achieve the effect of reducing wind breaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

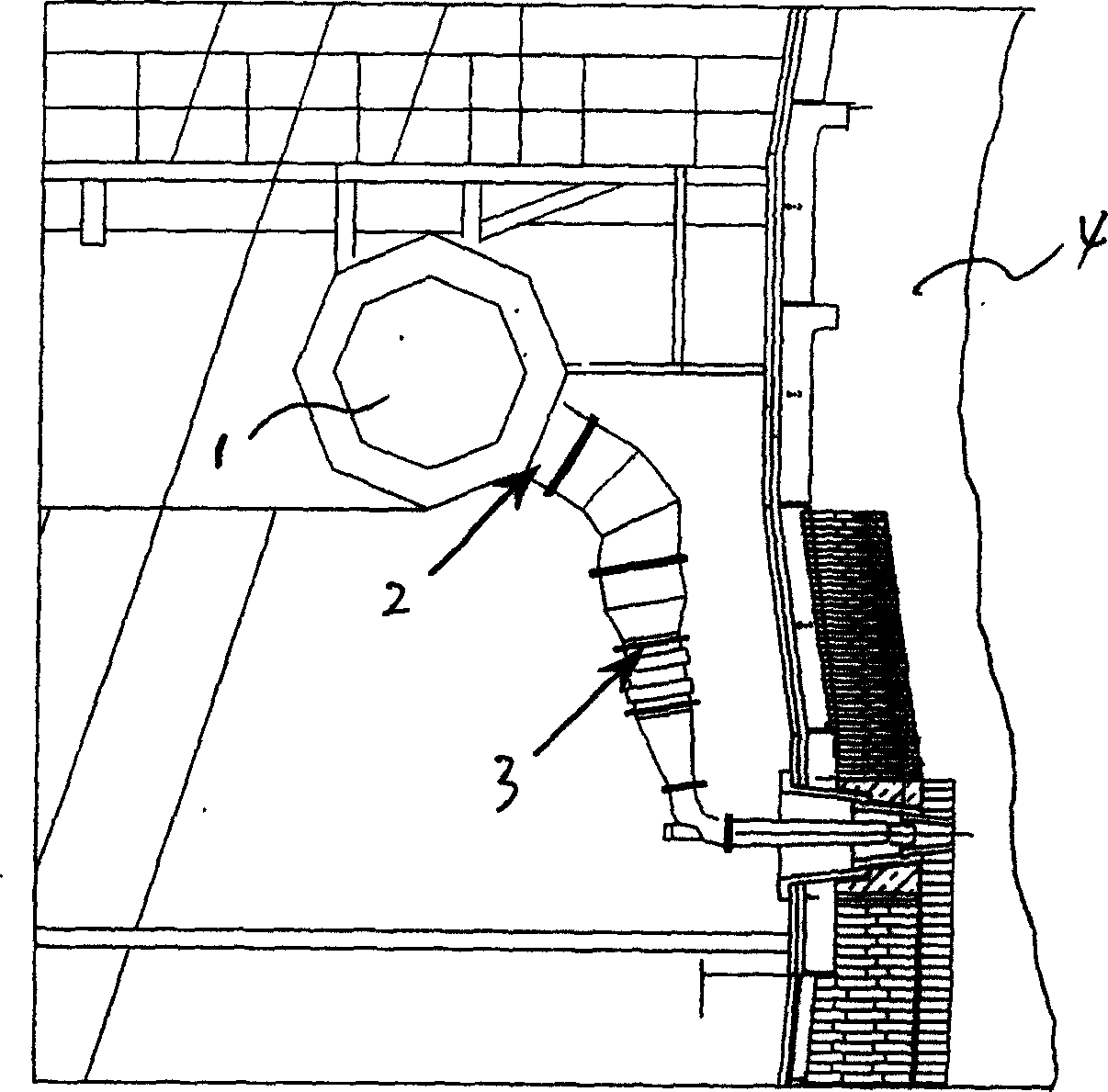

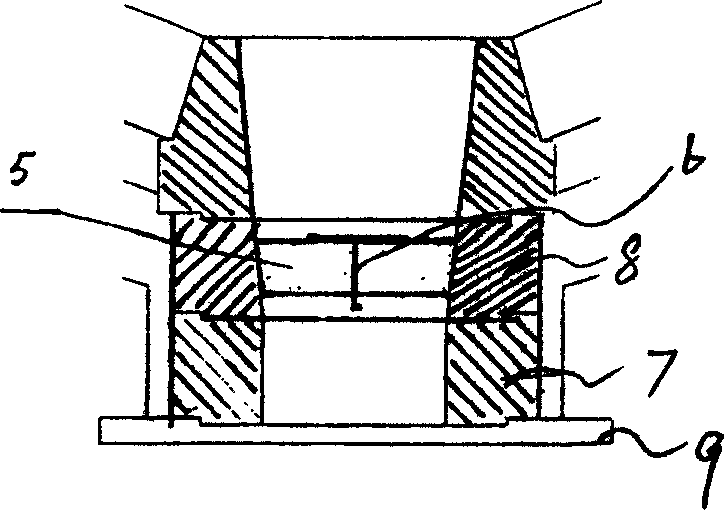

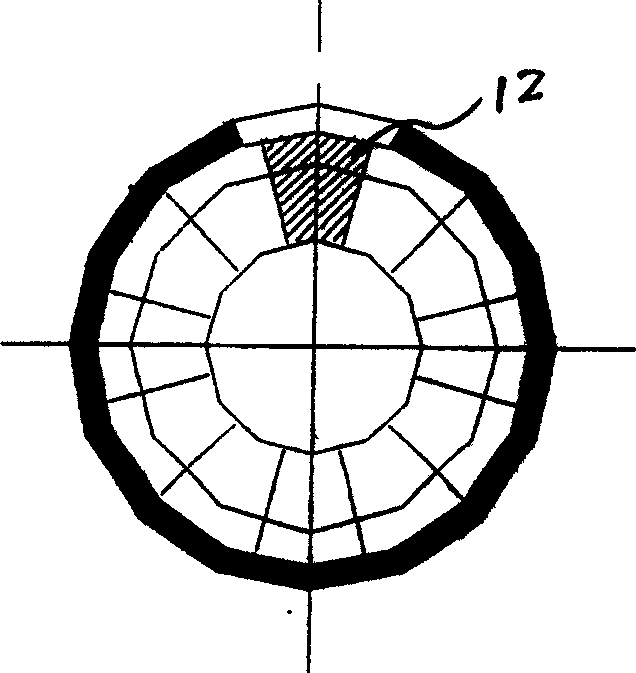

[0011] Embodiment 1: refer to figure 1 , the air supply branch pipe 3 is the thermal equipment connecting the surrounding pipe 1 and the blast furnace 4 tuyere, and it is the only channel for the hot air required to maintain the normal production of the blast furnace to enter the blast furnace 4 furnace. The transition part between the surrounding pipe 1 and the branch pipe 3 is called the branch Metatube 2. The branch pipe 2 is integrated with the surrounding pipe 1 in the inner lining structure, and its masonry method is to build bricks from the nozzle to the center of the surrounding pipe. When the inner lining of branch tube 2 is damaged and needs to be replaced, firstly seal and insulate branch tube 2: refer to figure 2 , since the implementation of this technology is carried out in the hot state of blast furnace shutdown, effective sealing and heat insulation is the prerequisite for the implementation of this technology, and the ceramic fiber cushion layer 5 containing...

Embodiment 2

[0012] Embodiment 2: set the arch tire in the branch pipe 2, the distribution of the flat iron is 3 points, and the rest are the same as the embodiment 1.

Embodiment 3

[0013] Embodiment 3: the distribution of flat irons is 5 points, and all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com