Water control method after blast furnace cooling wall breakage

A stave damage technology, applied in the direction of cooling devices, etc., can solve the cooling capacity of stave damage, affect the life of the stave, burn the stave, etc., to achieve the effects of prolonging life, maintaining operation safety, and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

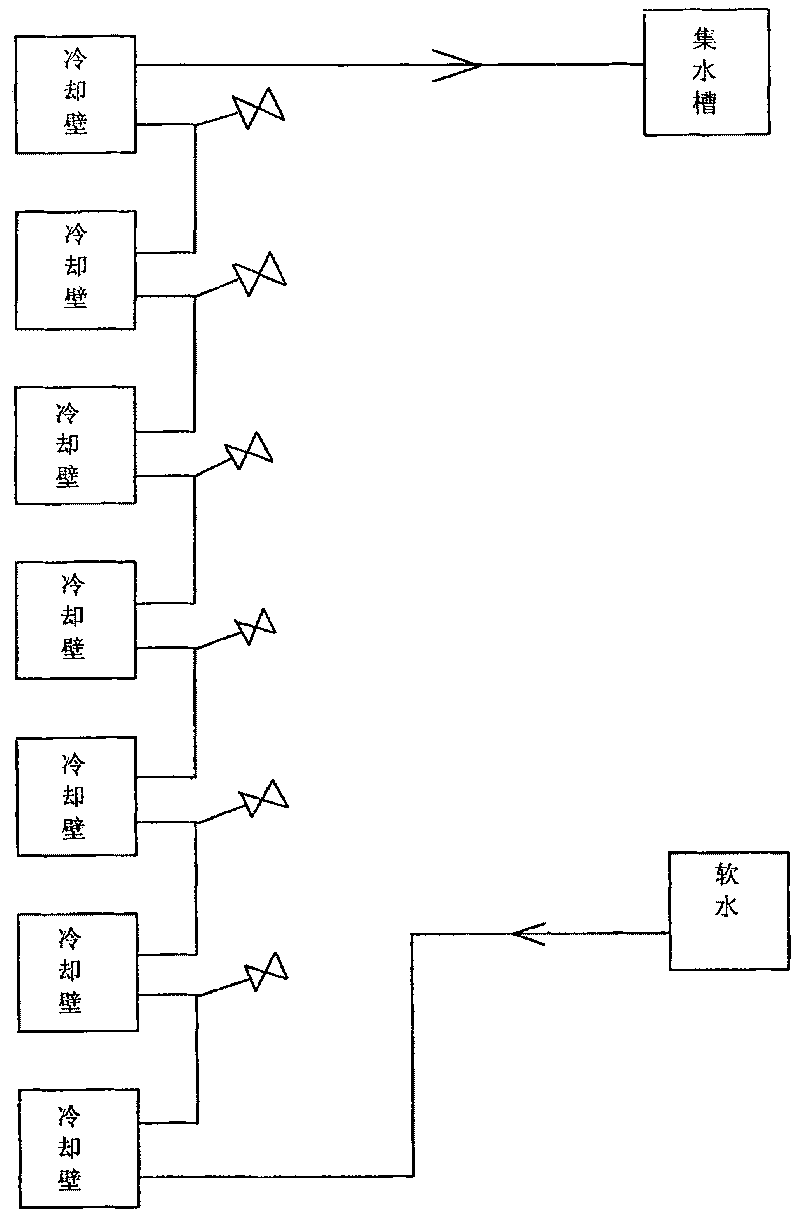

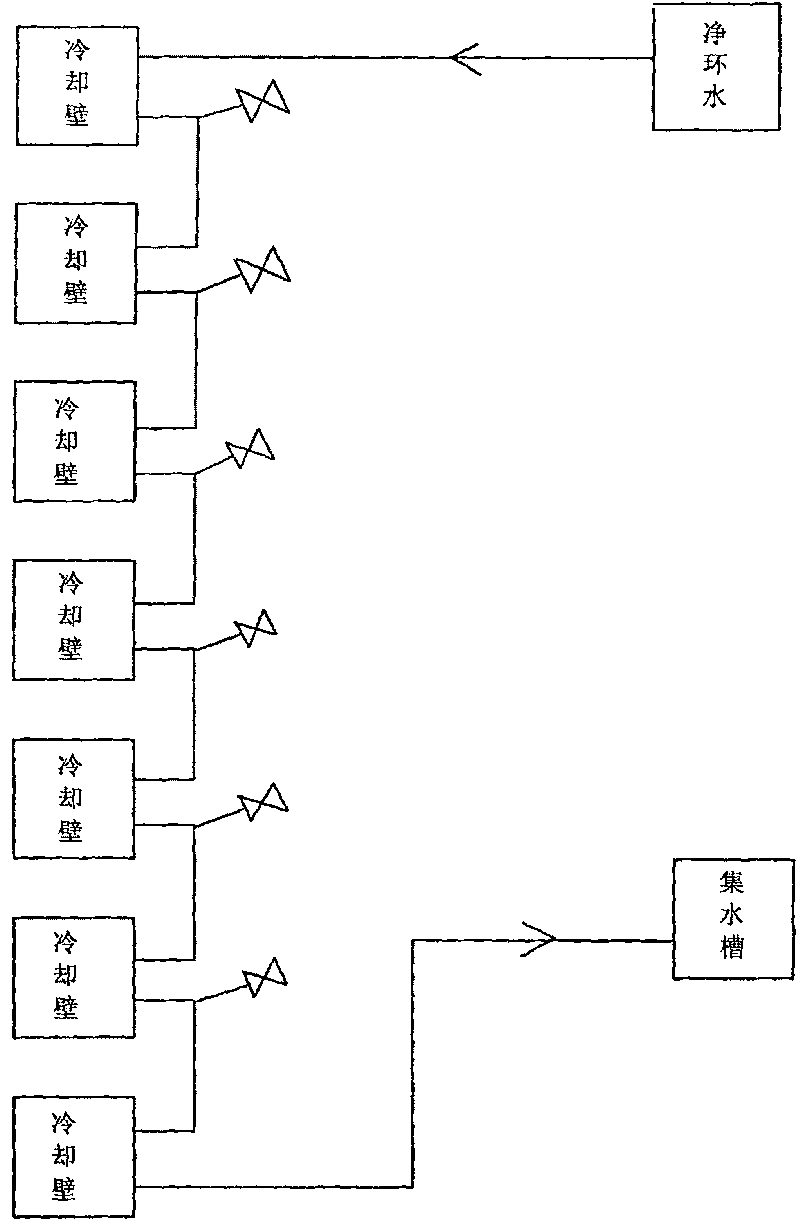

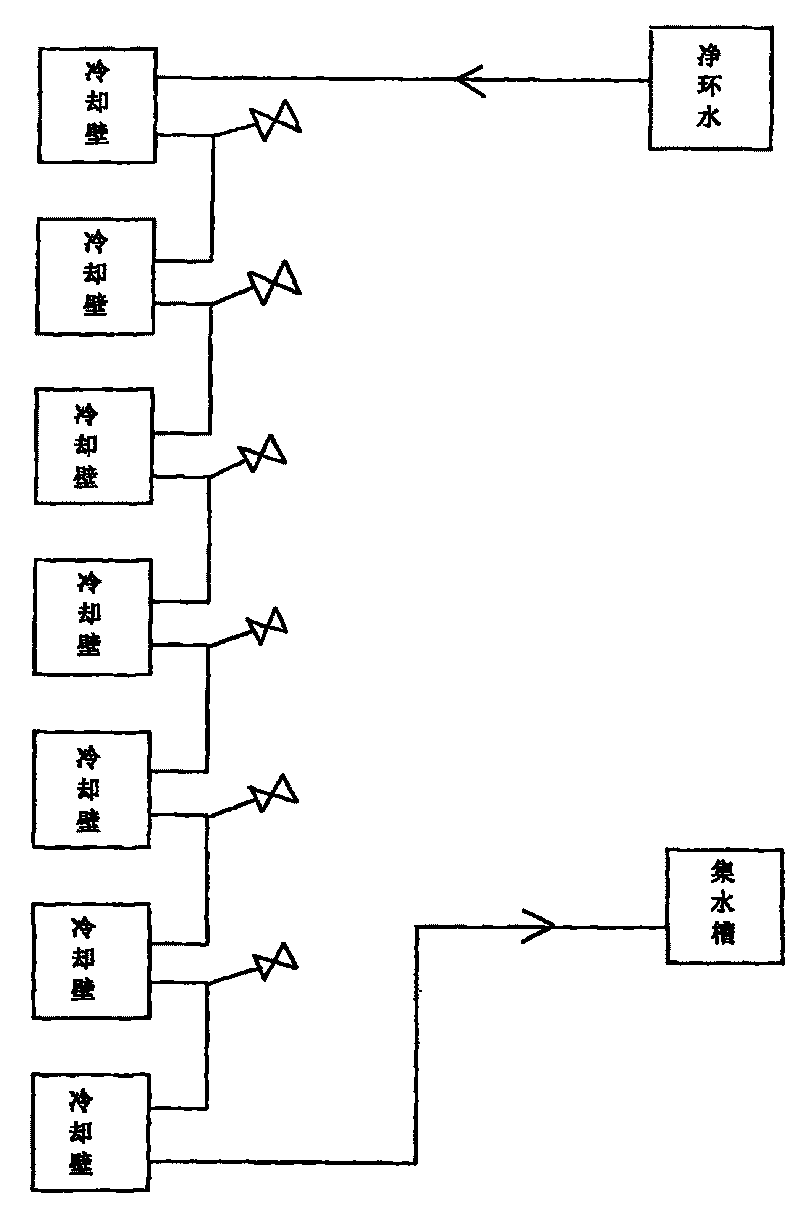

[0014] The schematic diagram of the water control method after the blast furnace stave is damaged in this embodiment is as follows figure 2 As shown, the water control method after the blast furnace stave is damaged is carried out according to the following steps:

[0015] (1) After determining that the stave is damaged, determine which string of staves the damaged point is located on;

[0016] (2) Replace the soft water of the series of cooling walls with clean ring water, and the clean ring water adopts the method of high inflow and low outflow, that is, the clean ring water enters from the uppermost part of the series of cooling walls and flows out from the bottom of the series of cooling walls , the water outlet of the net ring water is connected with the outside atmosphere;

[0017] (3) Adjust the water volume and flow rate to reduce the pressure in the channel of the series of staves, control the temperature of the outlet water and the gasp state to control the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com