Pull rod for air vent middle sleeve

A technology of sleeves and tie rods in the tuyere, which is applied in the direction of the tuyere, can solve the problems of affecting the replacement time, prone to slipping, and size mismatch, and achieve the effects of reducing the slipping of the tie rods, improving production efficiency, and shortening the wind break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

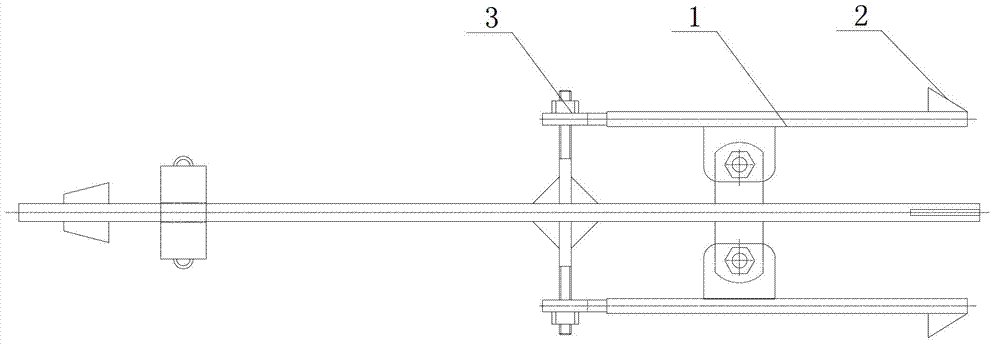

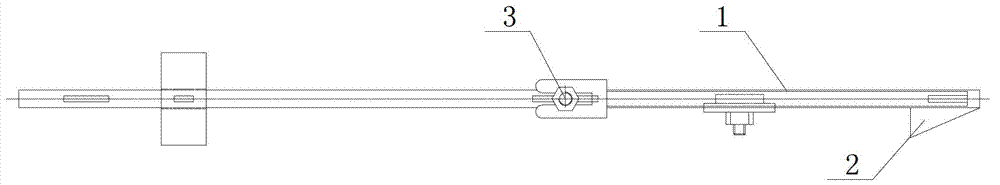

[0010] This embodiment provides a tie rod in the tuyere, the structure is as follows figure 1 and figure 2 As shown, the double-arm parallel pull rod composed of two pull rods 1 has a hook 2 at the front end of the double-arm parallel pull rod, and fastening bolts 3 are installed at the ends of the two pull rods to adjust the opening and closing degree of the front-end hook; the front end of the double-arm parallel pull rod The direction of the hook is turned inside out.

[0011] In this embodiment, the single-arm pull rod of the tuyere small sleeve is optimally designed as a double-arm parallel pull rod, and fastening bolts are installed at the ends of the two parallel double-arm pull rods. There will no longer be a slipping phenomenon of the pull rod during the middle sleeve, and the time for pulling down the middle sleeve is greatly shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com