Wall module of well walls and method for building wall bodies of well walls by using module

A wall and well wall technology, applied in buildings, building components, underwater structures, etc., can solve problems such as difficult to achieve bonding strength, cumbersome operation steps, complex structure, etc., to prevent the surrounding settlement, facilitate handling, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

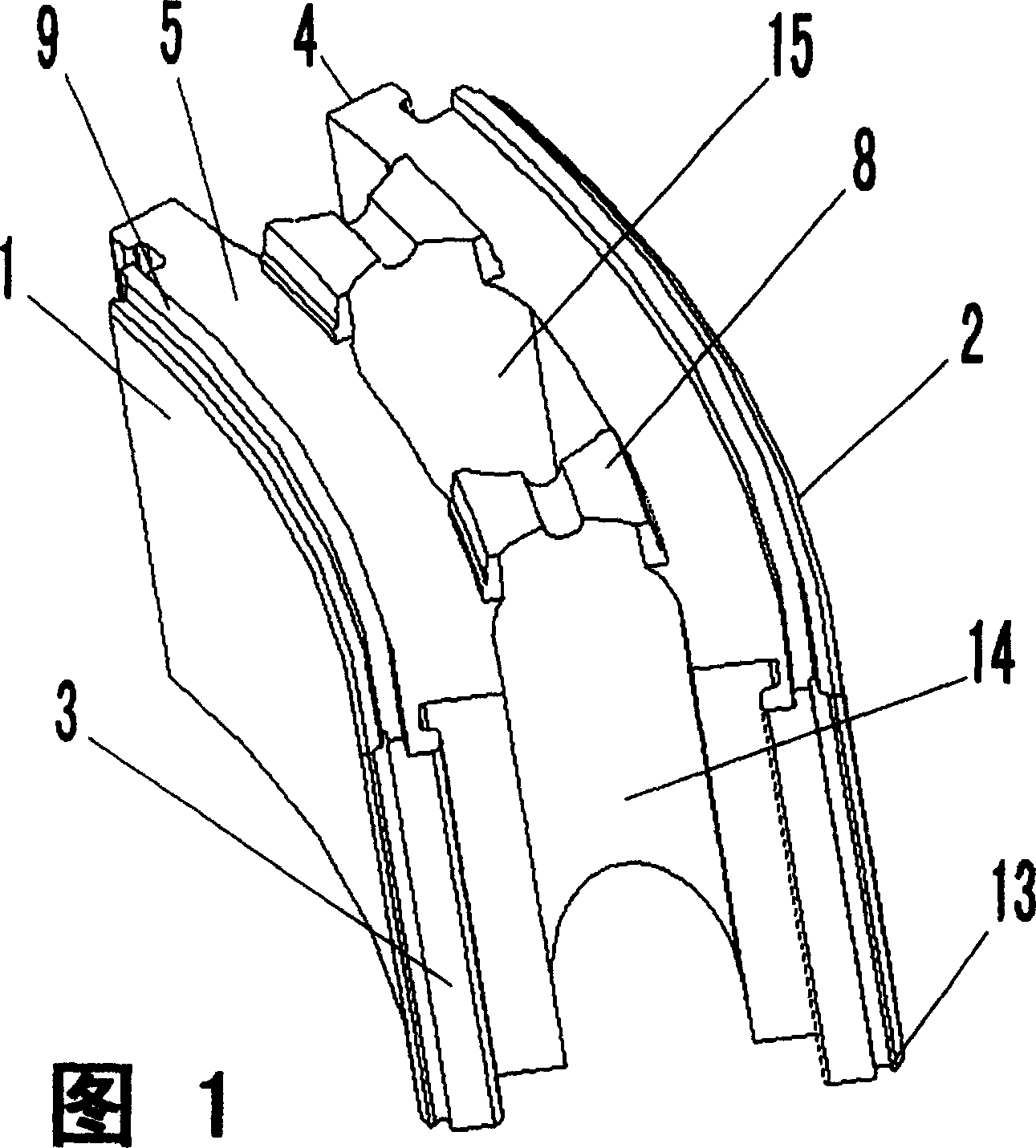

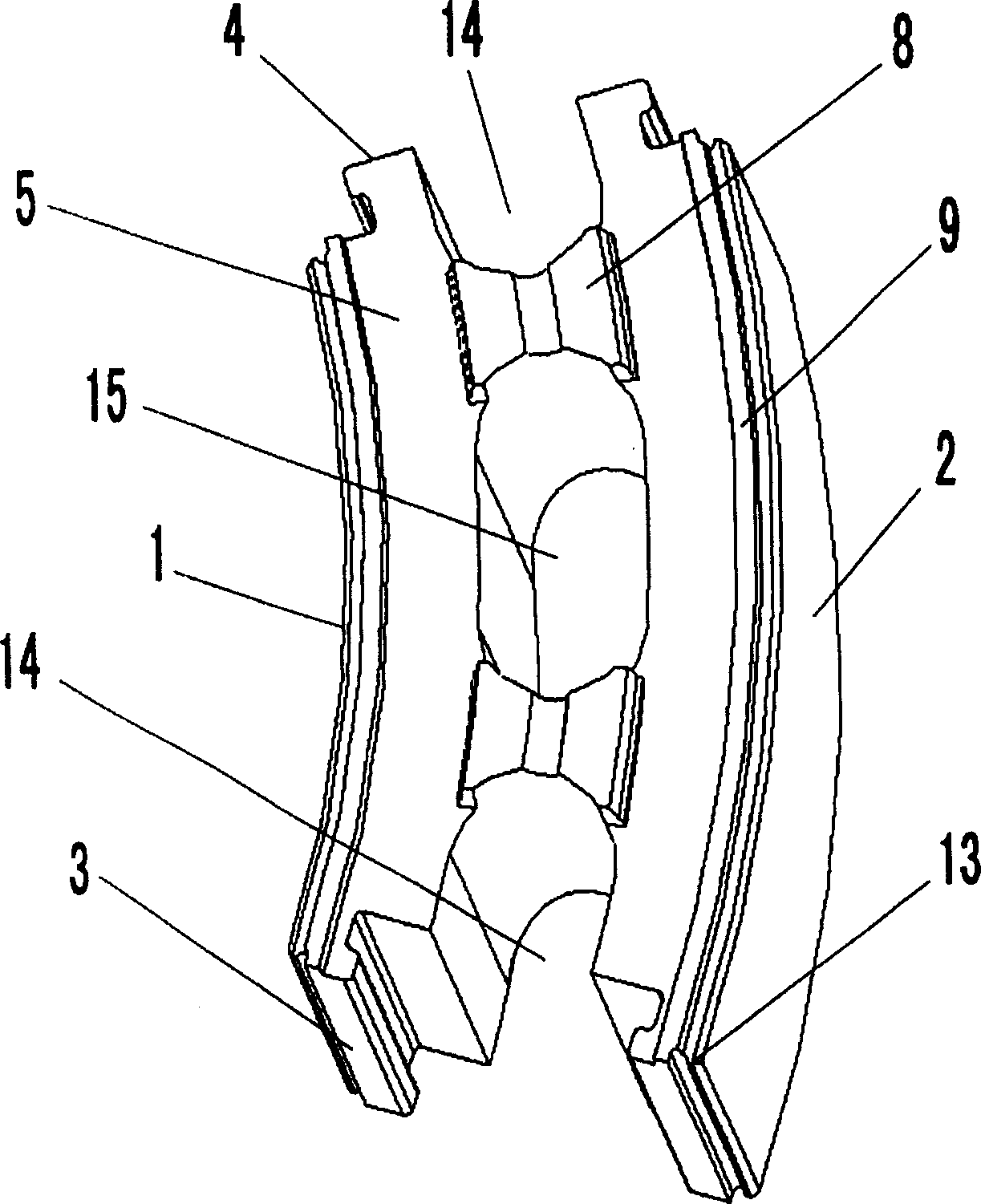

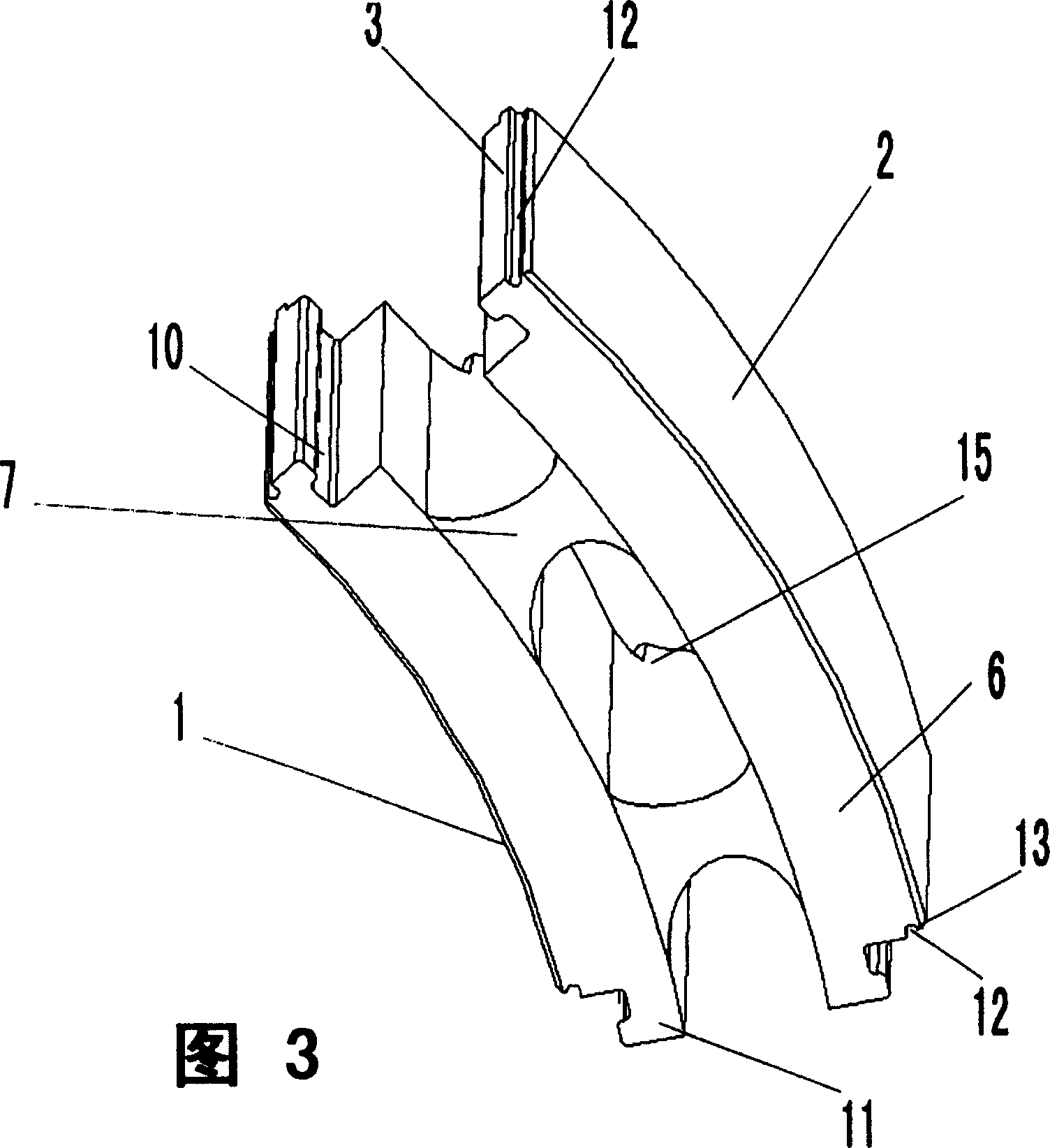

[0033] Referring to an embodiment of a shaft wall module of the present invention shown in Figures 1 to 3, in this embodiment, the shaft wall module includes a front surface 1, a rear surface 2, a pair of end surfaces 3, 4, an upper placement surface 5, a lower placement surface 6, at least one groove 7 recessed into the lower placement surface 6, and a boss 8 arranged on the upper placement surface 5, during masonry, The boss 8 corresponds to the groove 7 on the lower seating surface 6; the shape of the boss 8 is suitable for at least together with the groove 7 on the adjacent layer module to make the The modules are aligned; wherein the front surface 1 and the rear surface 2 are coaxial cylindrical arc surfaces, and the angle between the end surfaces 3 and 4 is consistent with the radians of the front and rear surfaces 1 and 2 . Adjacent to the front and rear surfaces 1 and 2, arc-shaped flanges 9 with the axes of the front and rear surfaces 1 and 2 as the center are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com