Digging and separating method for placer gold and equipment thereof

A sorting technology for alluvial gold, applied in mechanically driven excavators/dredgers, chemical instruments and methods, magnetic separation, etc., can solve problems such as poor separation efficiency, high cost of gold mining, and uneconomical mining, etc., to achieve Effects of improving efficiency and simplifying the sorting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

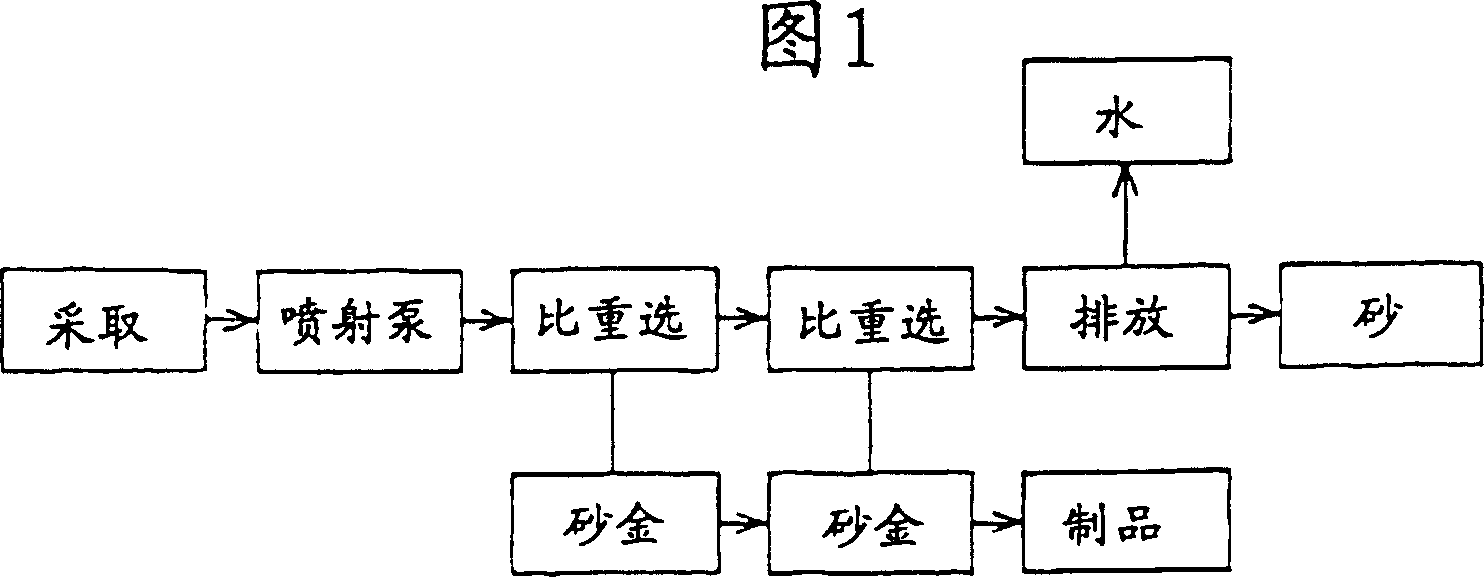

[0061] An embodiment of the present invention will be described with reference to FIG. 1 .

[0062] The mixture of sand and water that is sucked, excavated or mined from the bottom of the water is transported (for example, at a speed of 1 to 5 m / s) by means of a delivery pipe with a jet pump. Then, placer gold is separated by specific gravity difference in the part (separation box) where the cross-sectional area of the conveying pipe is enlarged. For example, if it is a separation box that increases the cross-sectional area of the delivery pipe by 20%, the flow velocity of the mixture of sand and water delivered at 3 m / s becomes 2.4 meters in the part (separation box) where the cross-sectional area is enlarged. / second, so the placer gold in the flowing mixture settles in the separation box. If the separation box (the large section of the pipe) for selecting placer gold etc. by means of specific gravity difference is connected in series at 2 places, then the larger place...

Embodiment 2

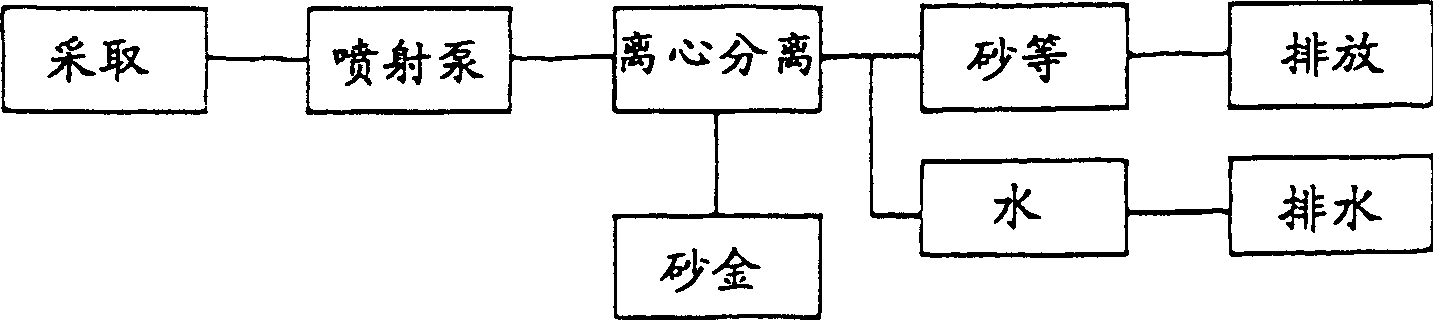

[0064] refer to figure 2 Another embodiment of the present invention will be described.

[0065] The mixture of sand and water that is sucked, excavated, or mined from the bottom of the water is transported by a delivery pipe with a jet pump. Then the mixture is put into a cyclone for centrifugation, so that the separated mixture of placer gold and the like is returned to the water again, and the separated placer gold and the like are collected and utilized. According to the cyclone of this embodiment, the placer gold and the like settle along the inner wall of the cylindrical outer tank, and other substances settle near the center of the cylindrical outer tank by utilizing the difference in specific gravity.

Embodiment 3

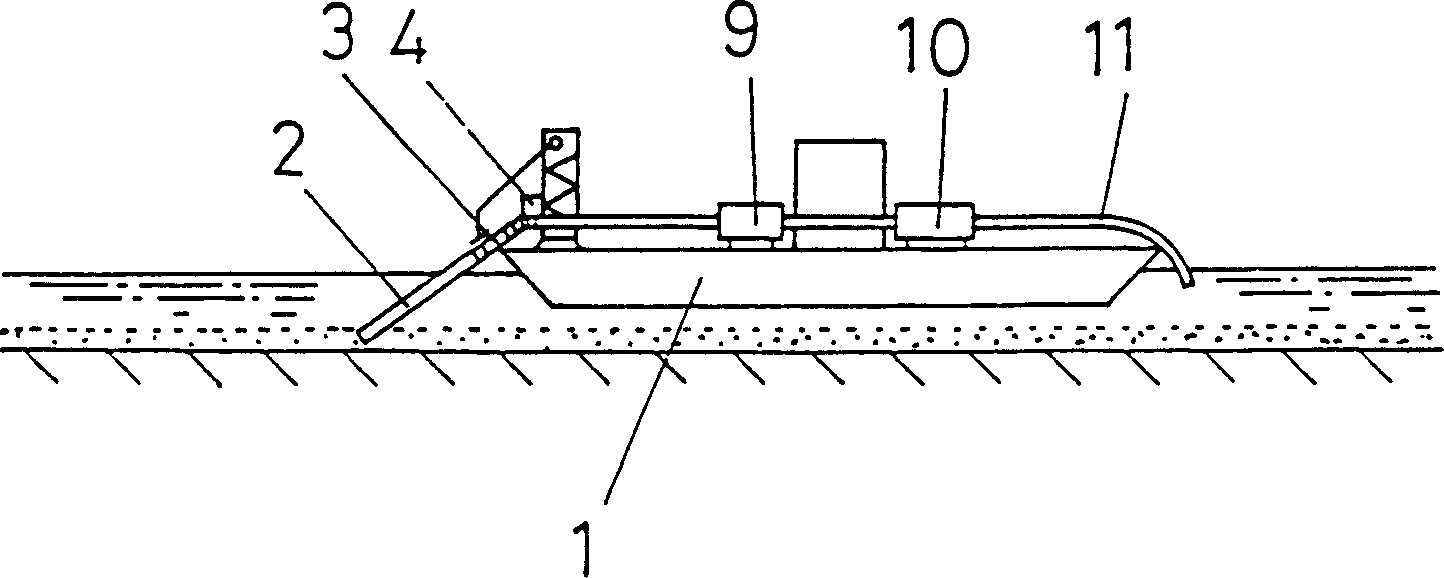

[0067] refer to image 3 , 4 , 5, 6, 7, 8 illustrate another embodiment of the present invention.

[0068] The base of the suction pipe 2 is movably installed on one side of the hull 1, the front end of the suction pipe 2 protrudes from the hull 1, and at the same time, one end of the hose 3 is connected to the base of the suction pipe 2, and the other end of the hose 3 Connected to jet pump 4. Jet pump 4 is provided with the spray hole 6 that sprays pressurized gas near the junction of described flexible pipe 3 and delivery pipe 5, and pressurized gas is supplied by the gas pipe 8 that is connected to gas box 7 ( Figure 6 ). Separation boxes 9, 10 ( image 3 ), the discharge hose 11 is connected to the discharge side of the final selection box 10, and the discharge hose 11 protrudes from the stern of the hull 1 to the outside.

[0069] In this embodiment, if the rod 12 fixed to the base of the suction tube 2 is moved in the direction of the arrow 14 or 15 by supplying a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com