Electric arc welder and electrode holder thereof

An arc welding machine and arc welding technology, which is applied in the field of arc welding machines and arc welding torches, can solve problems such as maintenance, and achieve the effects of constant welding wire melting, constant welding size, and low deformation of welded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

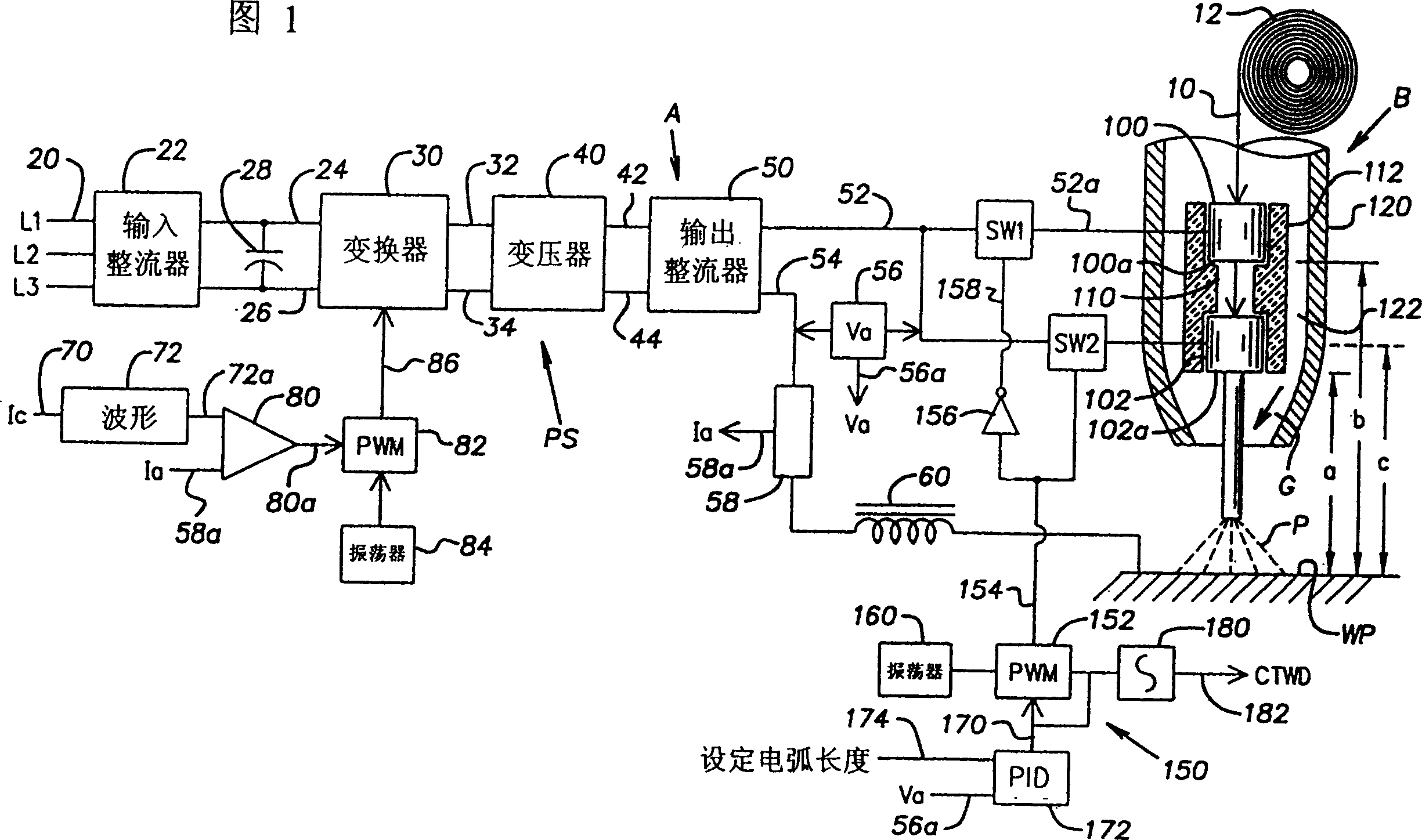

[0021]With reference to accompanying drawing, wherein accompanying drawing is only in order to show the preferred embodiment of the present invention and is not in order to limit the present invention, Fig. 1 has shown to welding torch or welding torch B provides welding current so that welding torch can carry out the constant voltage type arc welding of welding operation Machine A. A consumable welding electrode or wire 10 supplied by a standard spool 12 and directed through a torch or torch B towards a workpiece WP is melted at the arc P. As the arc melts the end of the welding wire 10, the molten metal is transformed into a weld bead on the workpiece WP. The power supply PS is not part of the invention and is provided according to standard construction. In the invention shown, the power supply is a commutator; however, conventional non-commutator power supplies could also be used. A three-phase input 20 drives an input rectifier 22 to produce a DC voltage between leads 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com