Touch screen disassembling platform

A touch screen and platform technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of increased disassembly difficulty, touch screen damage probability, poor temperature control, long working time, etc., to reduce manpower consumption, reduce disassembly difficulty and damage Probability, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

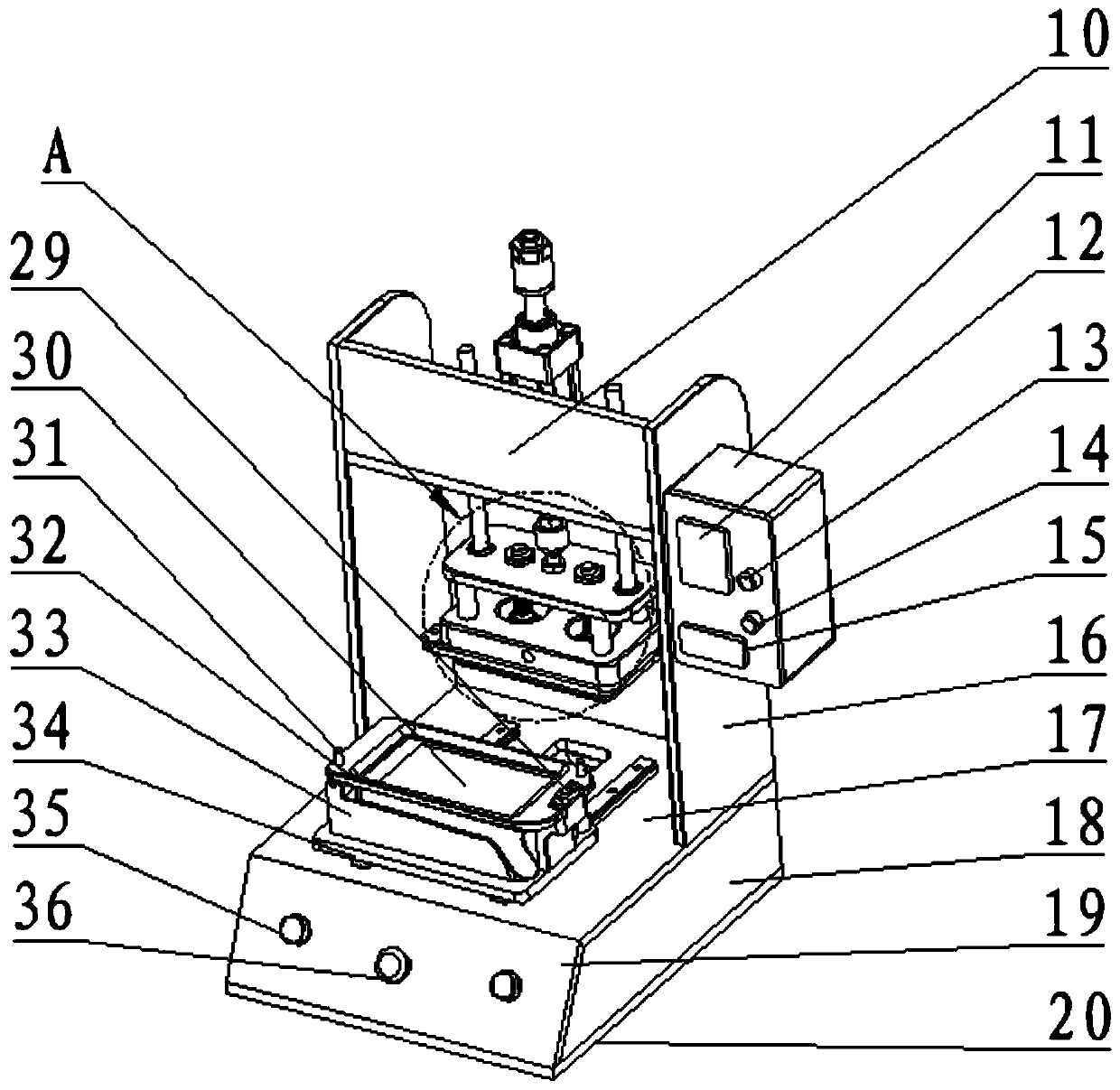

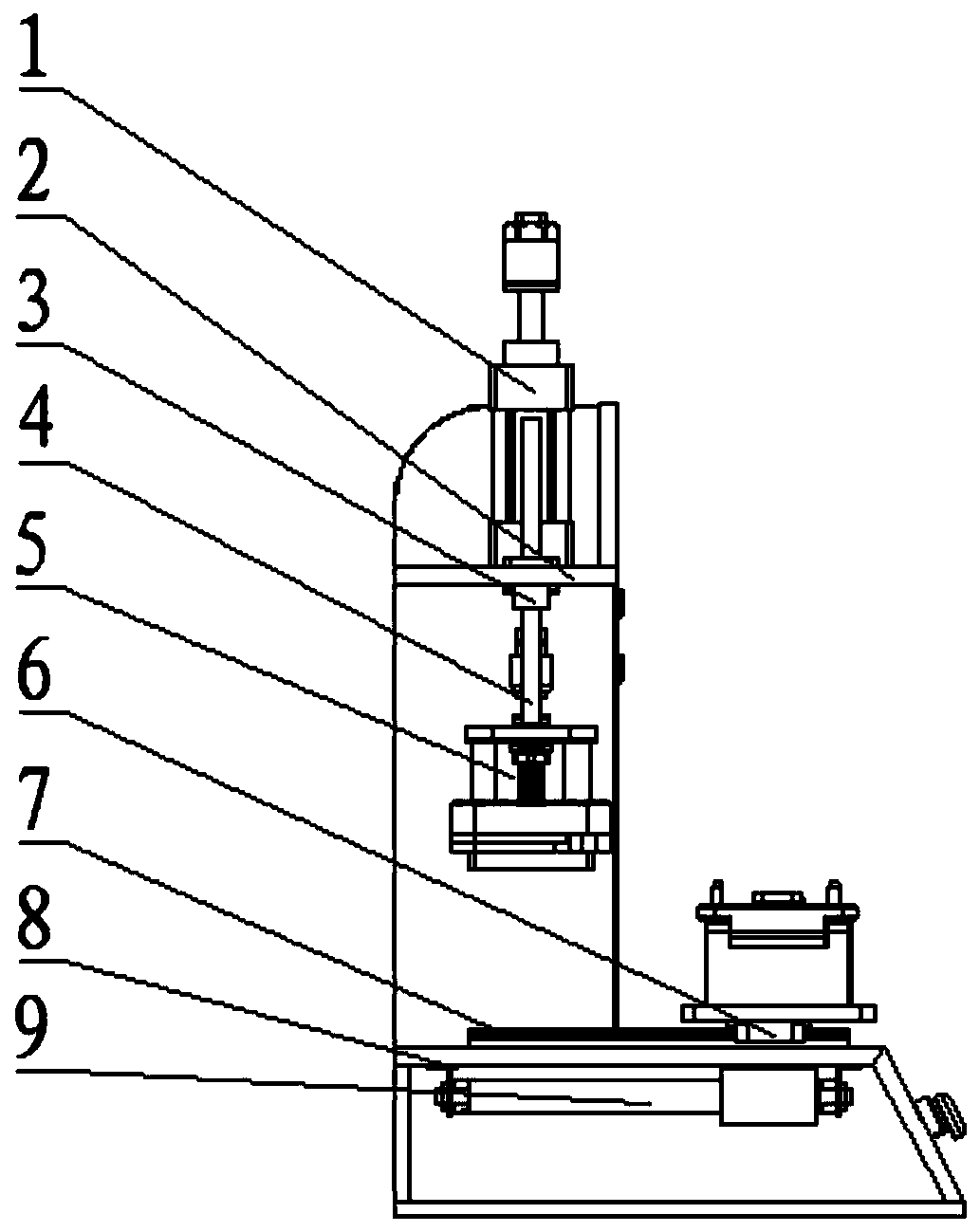

[0067] Please refer to Figure 1 to Figure 6 , a touch screen removal platform, including a frame module and a heating separation module 5;

[0068] The frame module includes a frame panel 17 and a module carrier plate 33;

[0069] The module carrier 33 is arranged on the frame panel 17, and the module carrier 33 is used to place the touch screen module 30 to be disassembled;

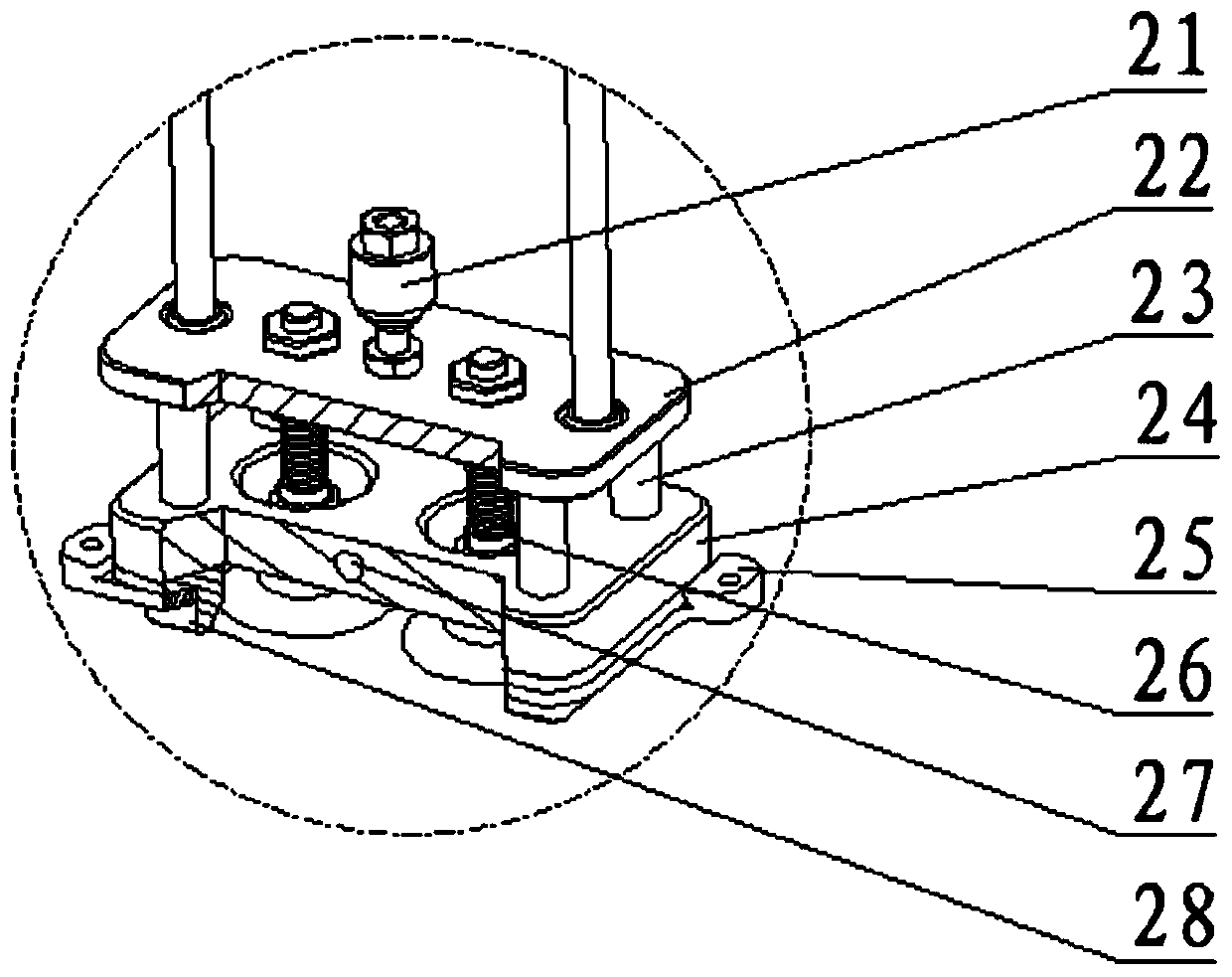

[0070] The heating separation module 5 includes a top cylinder 1, a heating copper block 24, a heat-conducting silica gel block 28 and a high-temperature-resistant suction cup 26;

[0071] The top cylinder 1 is arranged above the module carrier plate 33, and the movable end of the top cylinder 1 is arranged toward the module carrier plate 33 and connected to the heating copper block 24, and the heating copper block 24 The bottom is provided with a heat-conducting silica gel block 28 hollowed out in the middle, and the bottom of the heating copper block 24 is provided with a high-temperature-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com