Equal line speed turning device for making large screen template

A processing device and line speed technology, which is applied in feeding devices, metal processing, automatic control devices, etc., can solve the problems that cannot be realized, and the spindle head cannot control the infinitely variable movement of the worktable, so as to improve quality and efficiency and avoid vibration. The effect of vibration and knife breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

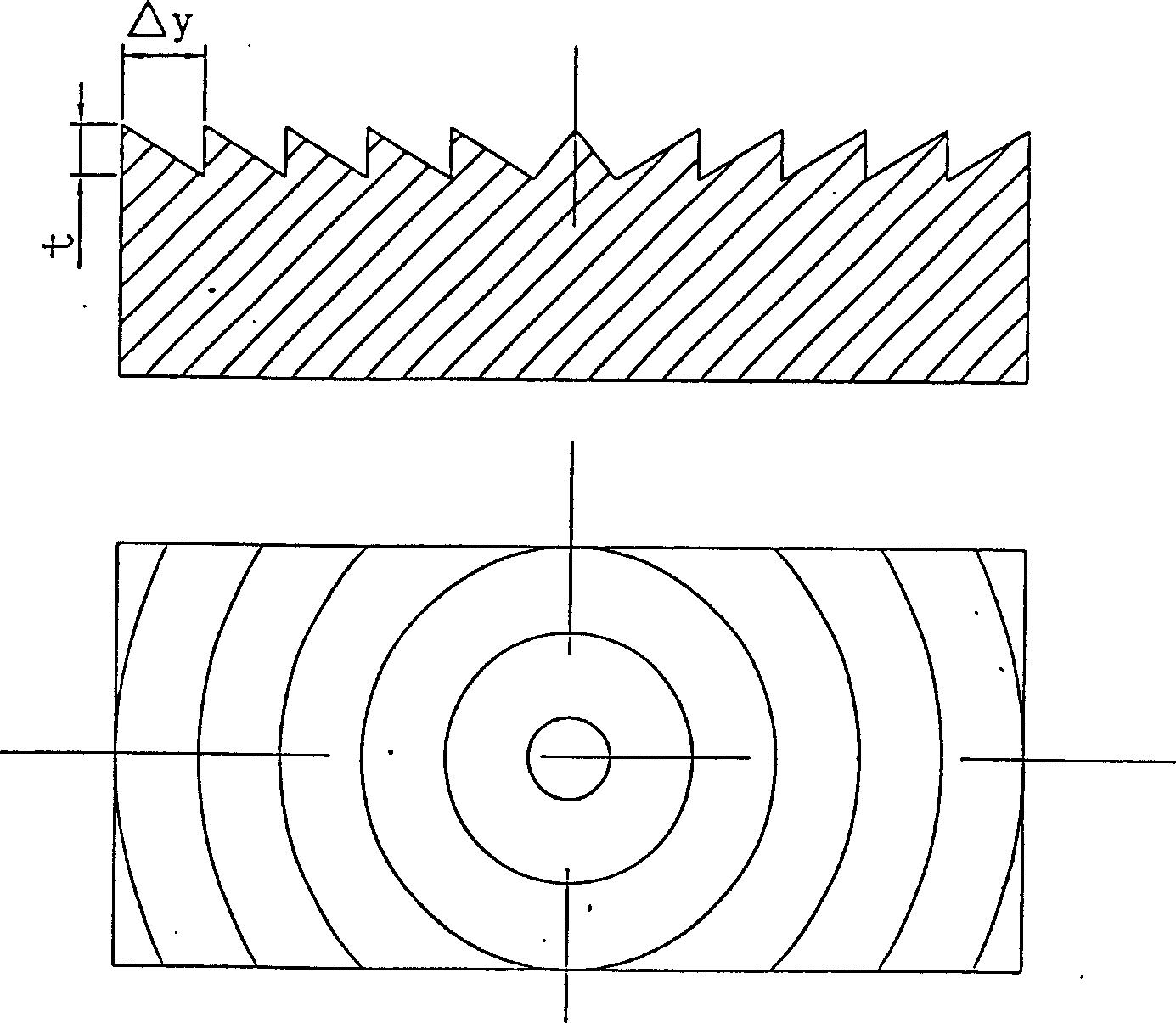

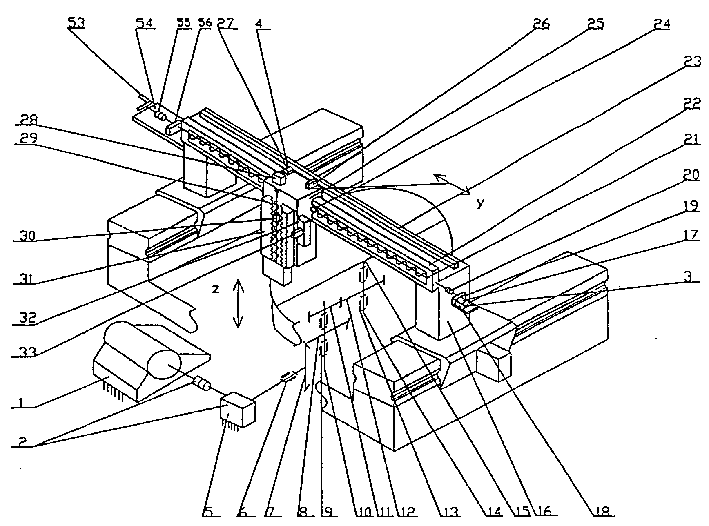

[0012] Such as figure 1 As shown, the present invention mainly includes: a DC speed regulating motor 1, a turntable transmission mechanism 2, a knife row y-direction indexing mechanism 3, a knife row z-direction advance and retreat mechanism 4, a turntable 15, a grating ruler 23, and the output of the motor 1 is transferred The input of the table transmission mechanism 2, the base of the turntable transmission mechanism 2 is consolidated with the foundation, the large carriage 25 in the y-direction indexing mechanism 3 of the knife row is set on the beam, and the z-direction advance and retreat mechanism 4 of the knife row is set on the large carriage 25 on. The computer controls the DC motor 1 to drive the turntable in the turntable transmission mechanism 2 to perform stepless speed change. The y-direction indexing mechanism 3 of the cutter row completes the radial precision indexing movement Δy (stripe spacing) when the cutter row processes concentric circular stripes. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com