Luminous anti-forgery ink and its preparation method and use

An anti-counterfeiting ink, ink technology, applied in the direction of ink, application, household appliances, etc., to achieve the effect of easy identification, wide application range, and improved anti-counterfeiting level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

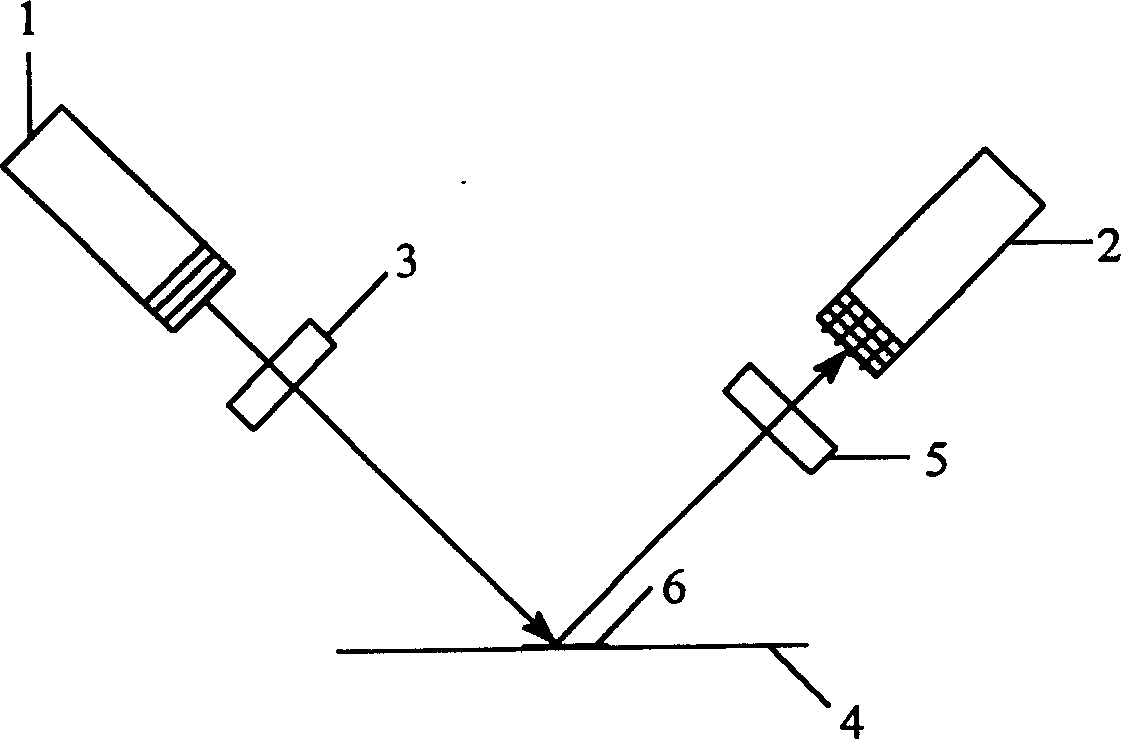

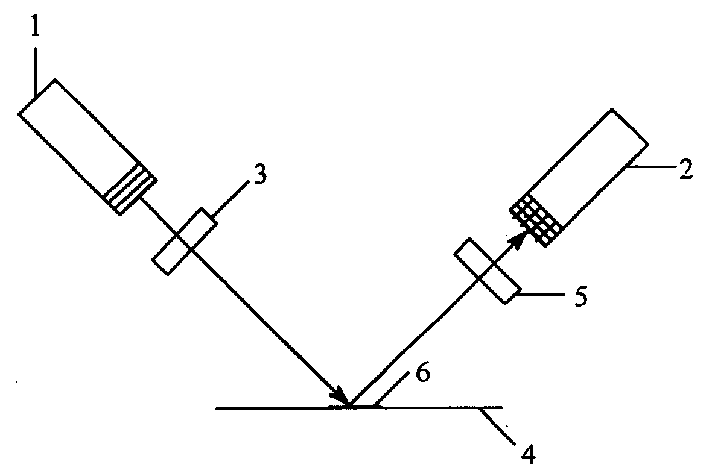

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of luminescent anti-counterfeiting ink

[0030] Weigh the molecular formula as 29.5Al(NH 4 ) 3 f 6 7.5CaF 2 7.5MgF 2 ·10BaF 2 43.5PbF 2 0.5Ho 2 o 3 50 grams of luminescent material, mixed with 150 grams of ink binder (80 grams of phenolic resin oil, 40 grams of alkyd resin oil, 30 grams of bright resin oil), appropriate amount of additives (8 grams of varnish, 0.5 grams of cobalt naphthalate) Stir and roll on a three-roll ink pad to prepare offset printing ink. The ink or its imprint emits blue-green light under the excitation of 632nm red light.

Embodiment 2

[0031] Example 2 Preparation of luminescent anti-counterfeiting ink

[0032] Weigh the molecular formula as 29.5Al(NH 4 ) 3 f 6 7.5CaF 2 7.5MgF 2 ·10BaF 2 43.5PbF 2 0.5Ho 2 o 3 80 grams of luminescent material, mixed with 130 grams of ink binder (80 grams of phenolic resin oil, 40 grams of alkyd resin oil, 30 grams of bright resin oil), appropriate amount of additives (8 grams of varnish, 0.5 grams of cobalt naphthalate) Stir and roll on a three-roll ink pad to prepare number ink. The ink or its imprint emits blue-green light under the excitation of 632nm red light.

Embodiment 3

[0033] Example 3 Preparation of luminous anti-counterfeiting ink

[0034] Weigh 50TeO 2 19.7PbF 2 10AlF 3 · i0BaF 2 ·NaF·0.3Tm 2 o 3 50 grams, mixed with 50 grams of ink binder and an appropriate amount of additives, stirred, and rolled on a three-roll ink machine to prepare screen printing ink. The ink or its imprint emits blue light when excited by red light at 650nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com