Production method for raising nitrogen content of granular complex fertilizer

A compound fertilizer and manufacturing method technology, applied in the direction of fertilizer form, fertilizer mixture, fertilization device, etc., can solve the problems of difficult production, uneven particle size, low granulation rate, etc., achieve no three wastes discharge, and reduce the requirement for vacuum degree , particle smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

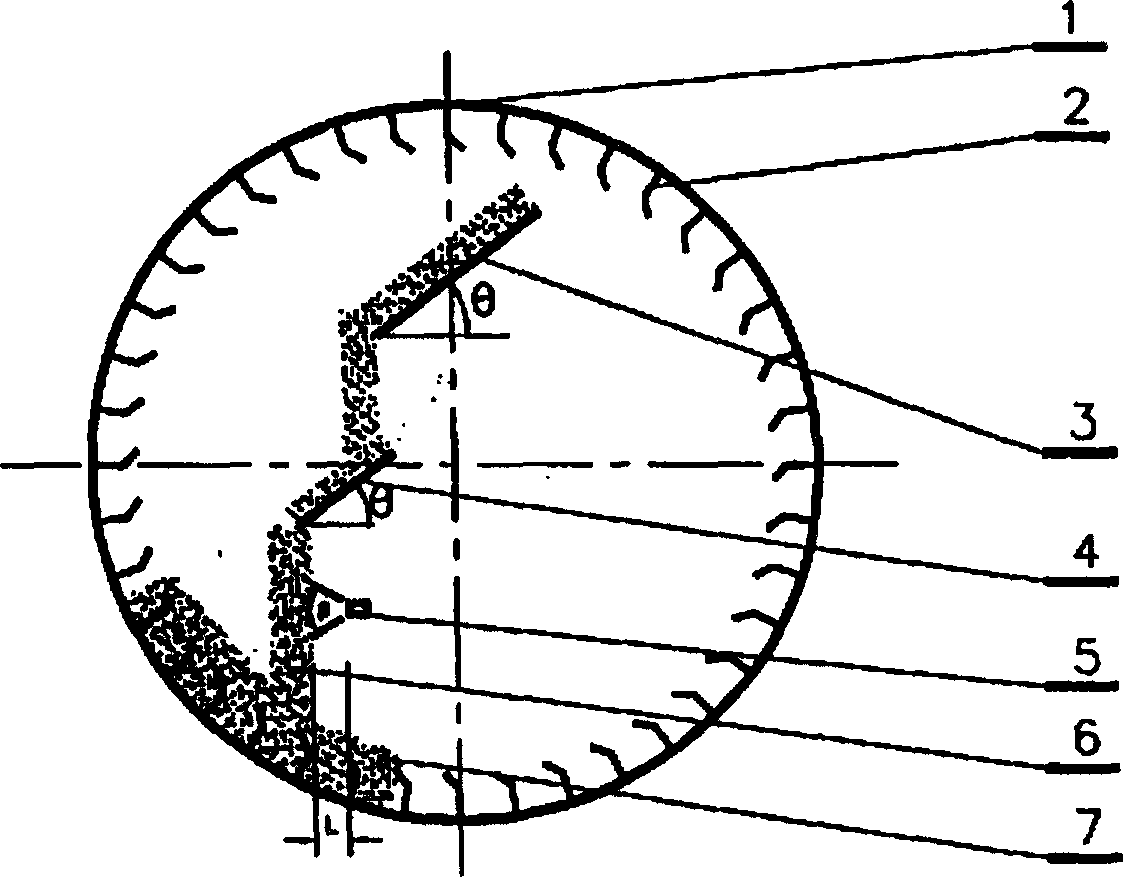

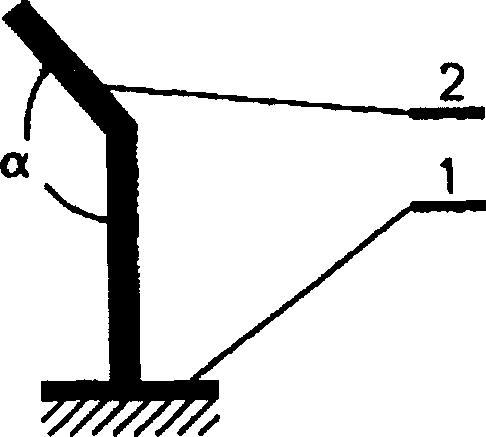

[0028] Take 200kg of urea solution from the outlet of the first stage of the evaporator separator in the urea production plant and pass it into the drum. The concentration of the urea solution itself is about 96%, the temperature is about 138°C, and the pressure is about 0.5MPa. Put 800kg of compound fertilizer in the drum in advance, and its formula is N-P 2 o 5 -K 2 O=10-17.5-17.5, particle diameter is 1-3mm. The drum rotates, and the lifting board on the drum wall lifts the low-nitrogen compound fertilizer from the bottom of the drum to the upper part of the drum, and the fertilizer particles fall onto the tray by gravity, forming a uniformly distributed curtain of fertilizer particles through the tray. The rotational speed of the drum was 4 rpm, and the inclination angle θ of the drum was 2°. The flight board is an inclined flight board, and the α angle of the flight board is 135°.

[0029] The urea solution passed into the drum is sprayed from the nozzle in the drum t...

Embodiment 2

[0031] In addition to taking 371kg of urea solution at the outlet of the first stage of the evaporator separator in the urea production plant, 629kg of compound fertilizer is preset in the drum. The rotating speed of the drum is 16 rpm, and the inclination angle θ of the drum is 6°. The α angle of the inclined shape lifting board is 140 °, all the other operating steps and process parameters are the same as embodiment 1, finally obtain 1000kg of compound fertilizers that improve nitrogen content, and its compounding formula is N-P 2 o 5 -K 2 O=22.5-11.25-11.25, the strength of the fertilizer particles is greater than 40 Newton / particle, and the moisture increment is not greater than 0.2%.

Embodiment 3

[0033] Take 196kg of solid urea, heat it to 140°C to make it a urea solution, add 4kg of water, pressurize it to about 0.5MPa through a urea melt pump, filter it through a filter equipped with a 200-mesh filter, and put it into the drum. It is equipped with a pressure nozzle, and the urea solution is sprayed from the nozzle, atomized into about 200 mesh or finer droplets, and evenly coated on the fertilizer particle curtain formed by the pre-added compound fertilizer. The amount of compound fertilizer added in advance is 800kg, and its formula is N-P 2 o 5 -K 2 O=10-17.5-17.5, particle diameter is 1-3mm. The rotational speed of the drum was 10 rpm, and the inclination angle θ of the drum was 8°. The flight board is an inclined flight board, and the α angle of the flight board is 135°. Obtain 1000kg of compound fertilizers that increase nitrogen content at last, and its compounding formula is N-P 2 o 5 -K 2 O=17.4-14-14, the strength of the fertilizer particles is greate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com