Filter devece for clarifying contaminated liquids

A filter device, sewage technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of deterioration of filtration efficiency, high technical cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

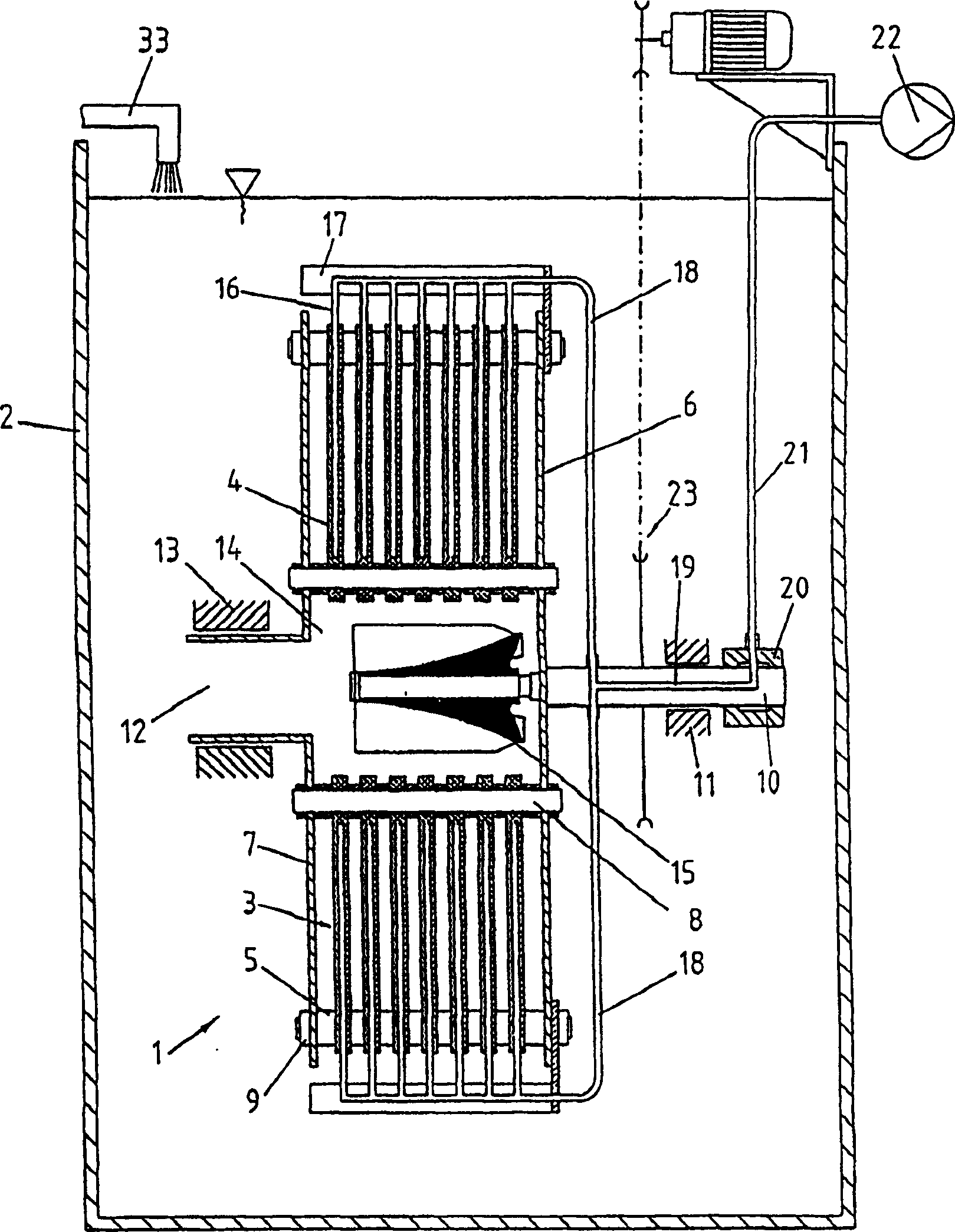

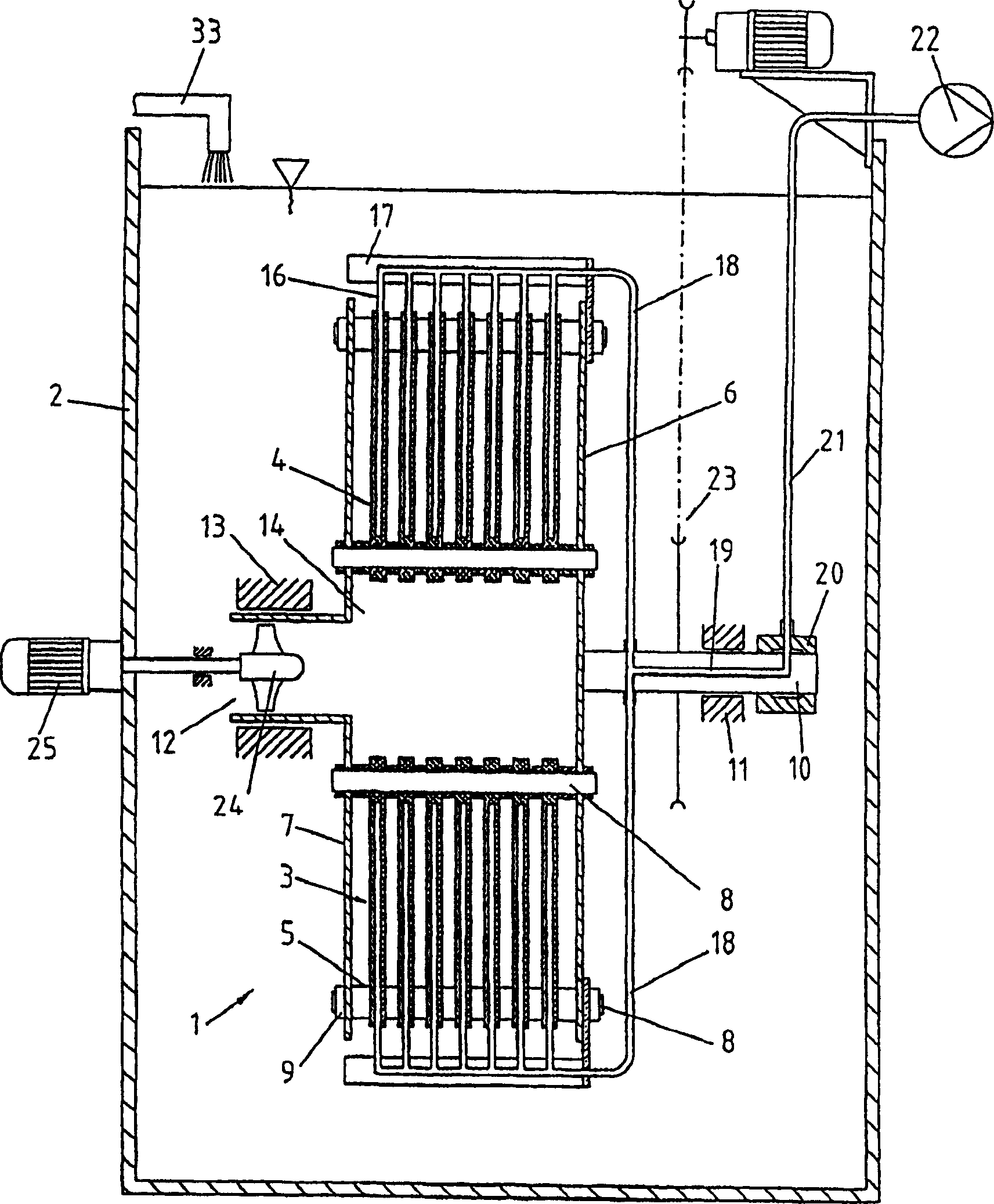

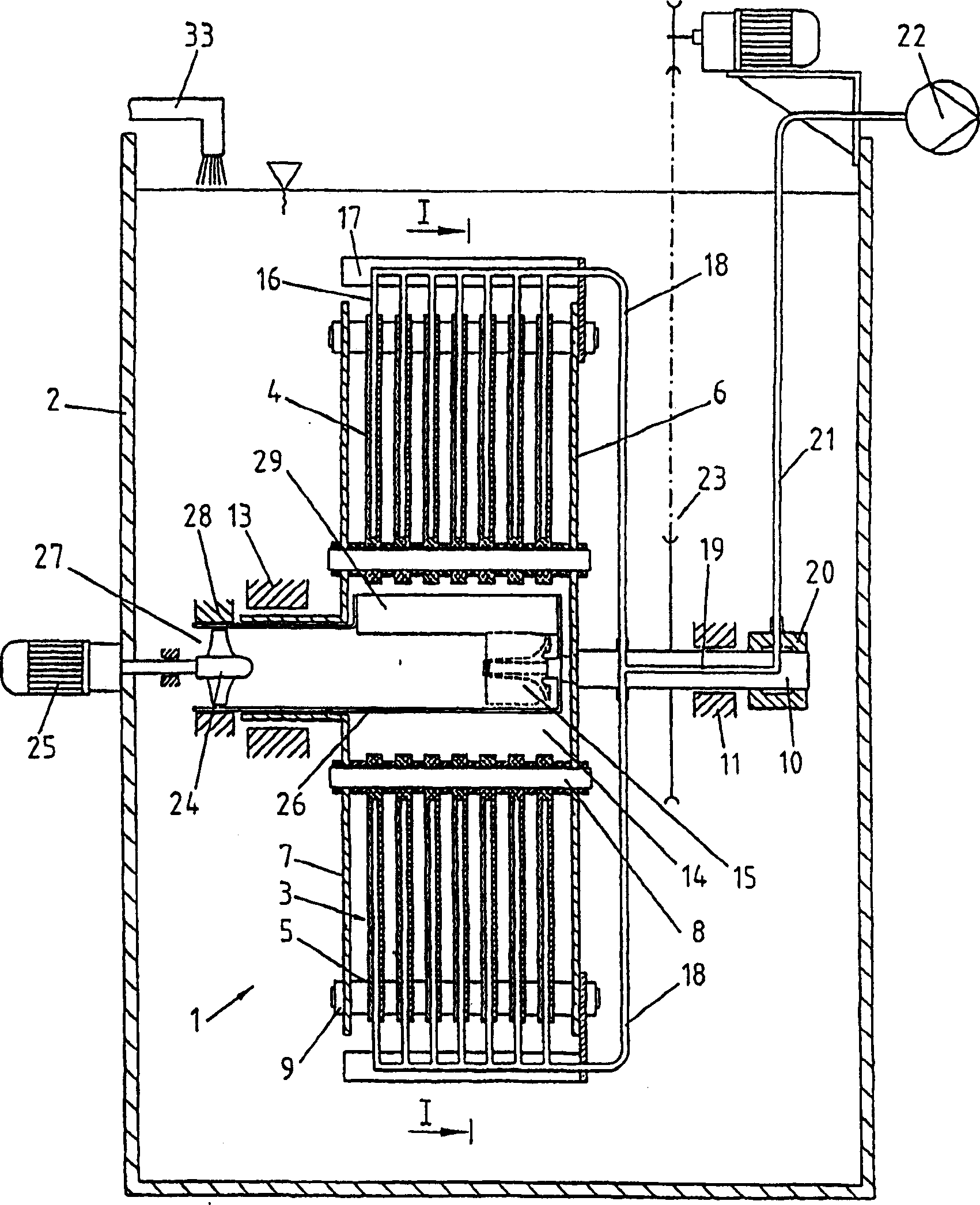

[0018] The filter device 1 is rotatably arranged in a container 2 containing a filter liquid. A plurality of filter assemblies 3 are arranged in a circle. The filter assembly 3 is composed of individual filter inserts 4 at a distance of preferably 4 to 8 mm. The filter insert 4, on the other hand, consists of known filter plates, not shown in the figures, through which the filtrate is discharged and which are provided with filters on both sides. The spacing between the filter elements 4 is ensured with spacers 5 . The filter assembly 3 is bounded on the one hand by a support plate 6 and on the other hand by a support flange 7 and is fastened with rods 8 and nuts 9 . The support disk 6 is fixedly connected to a drive shaft 10 and mounted rotatably in a bearing 11 . The support flange 7 has a suction opening 12 and is sucked into a seat 13 . The cavity 14 formed by the filter assembly 3 communicates through the suction hole 12 with the container 2 containing the filtered liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com