Method for manufacturing conductive plastic sheet

A plastic sheet material and manufacturing method technology, applied in the direction of heating methods, electrical components, electric heating systems, etc., can solve problems such as the difficulty of scaling up the use, the difficulty of adjusting the slit of the annular jaw gasket, etc., and achieve the manufacturing price and The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

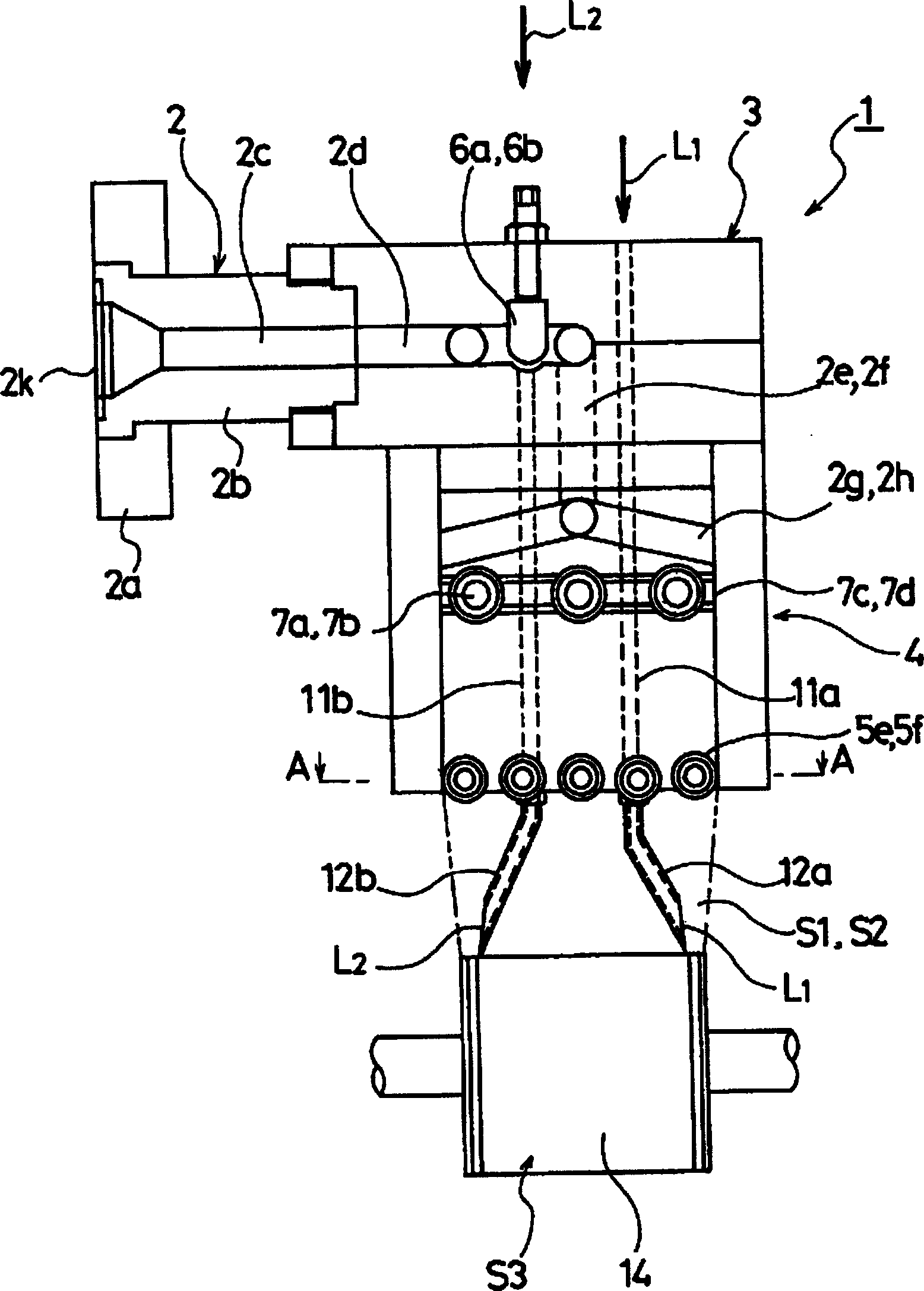

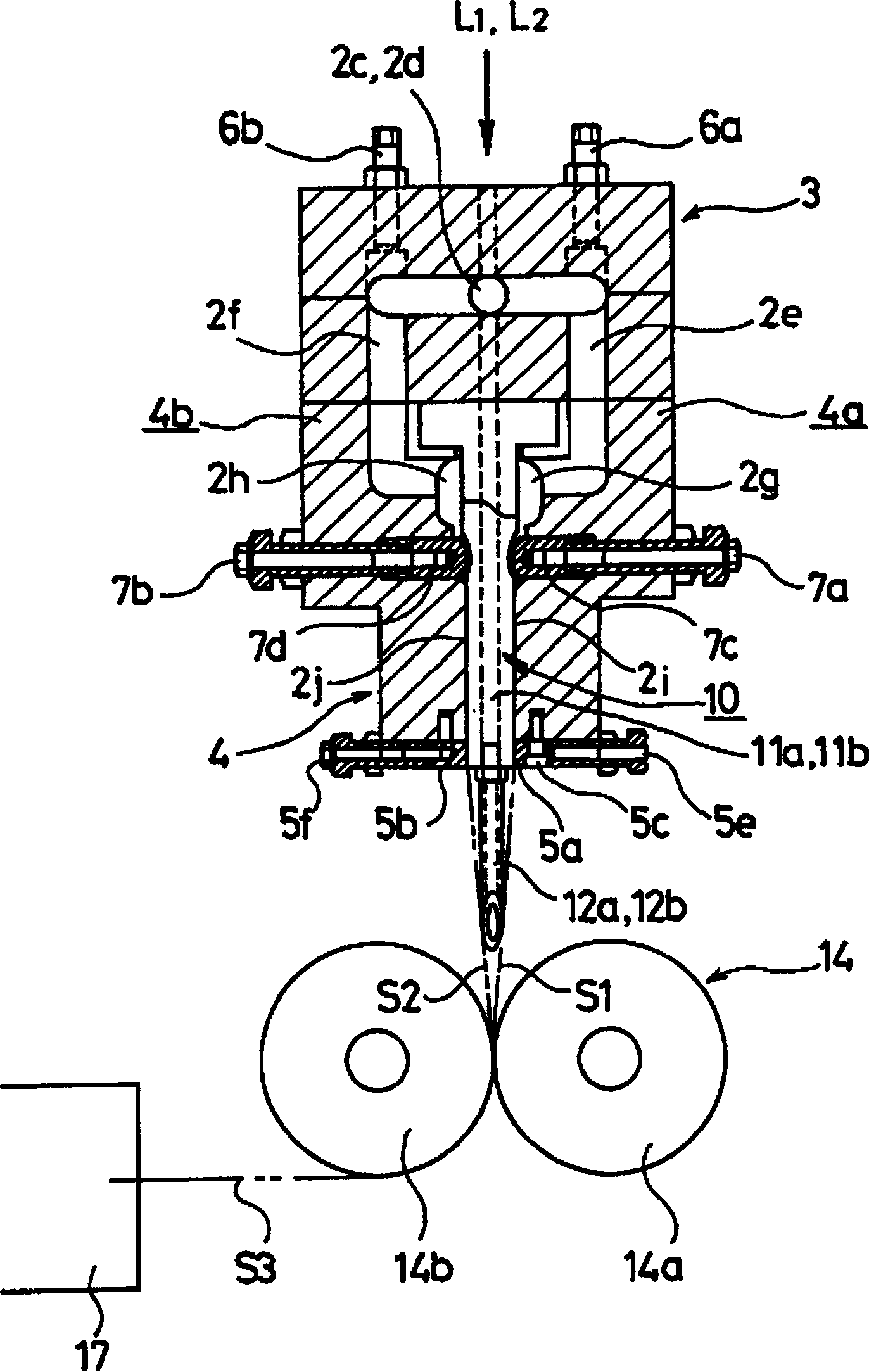

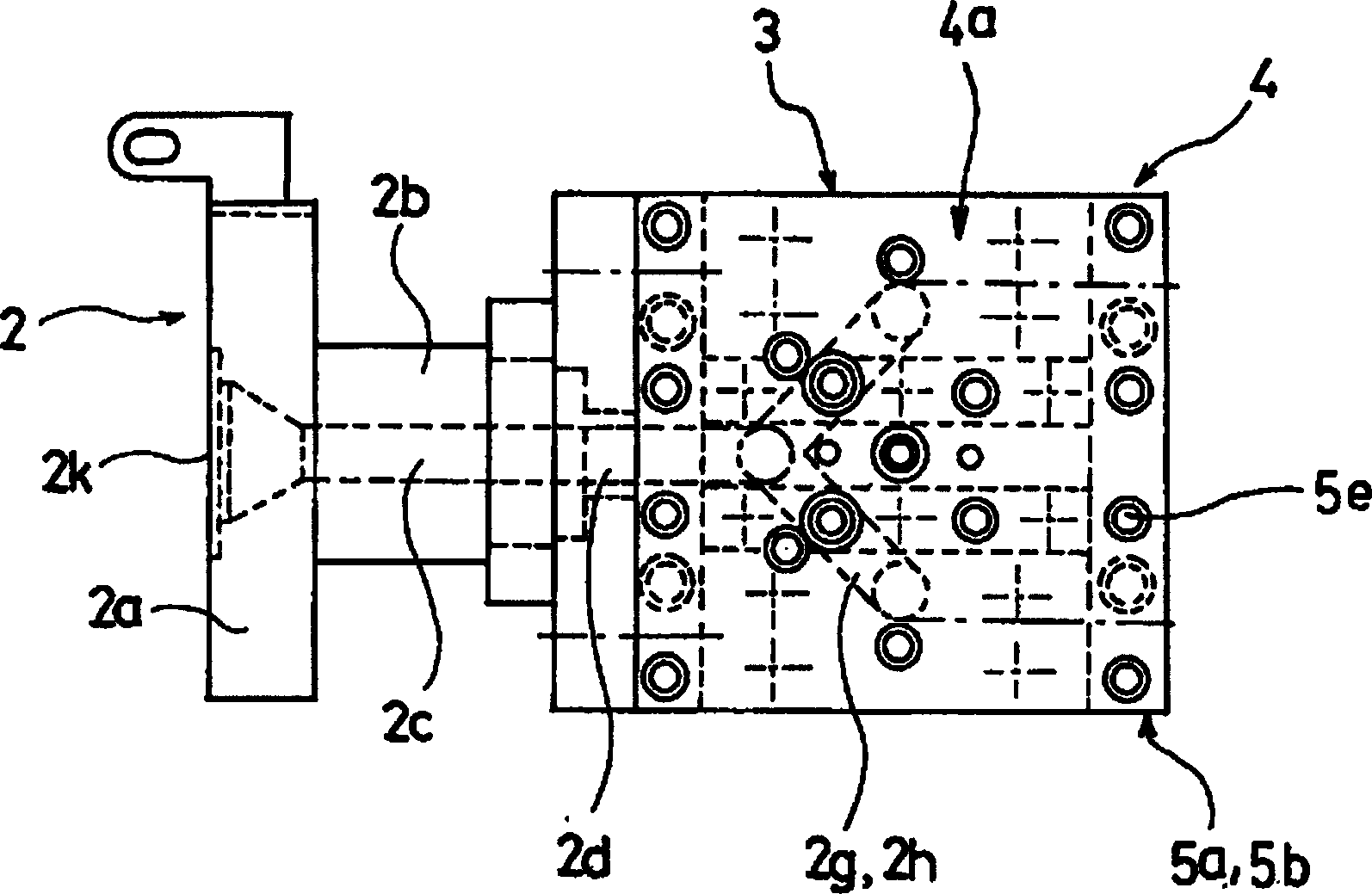

[0054] figure 1 It is a front sectional view of the forming apparatus of the conductive plastic sheet according to the embodiment of the present invention, figure 2 yes figure 1 A longitudinal section view of the device shown, image 3 is a plan view of the above forming device, Figure 4 is along figure 1 A cross-sectional view taken on line A-A in, Figure 5 6 is a schematic view showing the outline of the flow path of molten plastic in the metal mold, and FIG. 6 is a perspective view showing the outline of the entire molding device.

[0055] The forming device 1 of a conductive plastic sheet suitable for a planar heating element is composed of a metal mold device and an extrusion roller part 14. The former is a connection fitting 2 and a distribution fitting 3 connected to an extruder not shown in the figure. Composed of sheet material forming accessories 4; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com