Guided servo direction control valve

A directional control valve, servo-driven technology, applied in the direction of servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of complex system structure, high manufacturing cost, many leakage points, etc., to achieve simple system structure, reduce Additional energy consumption, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

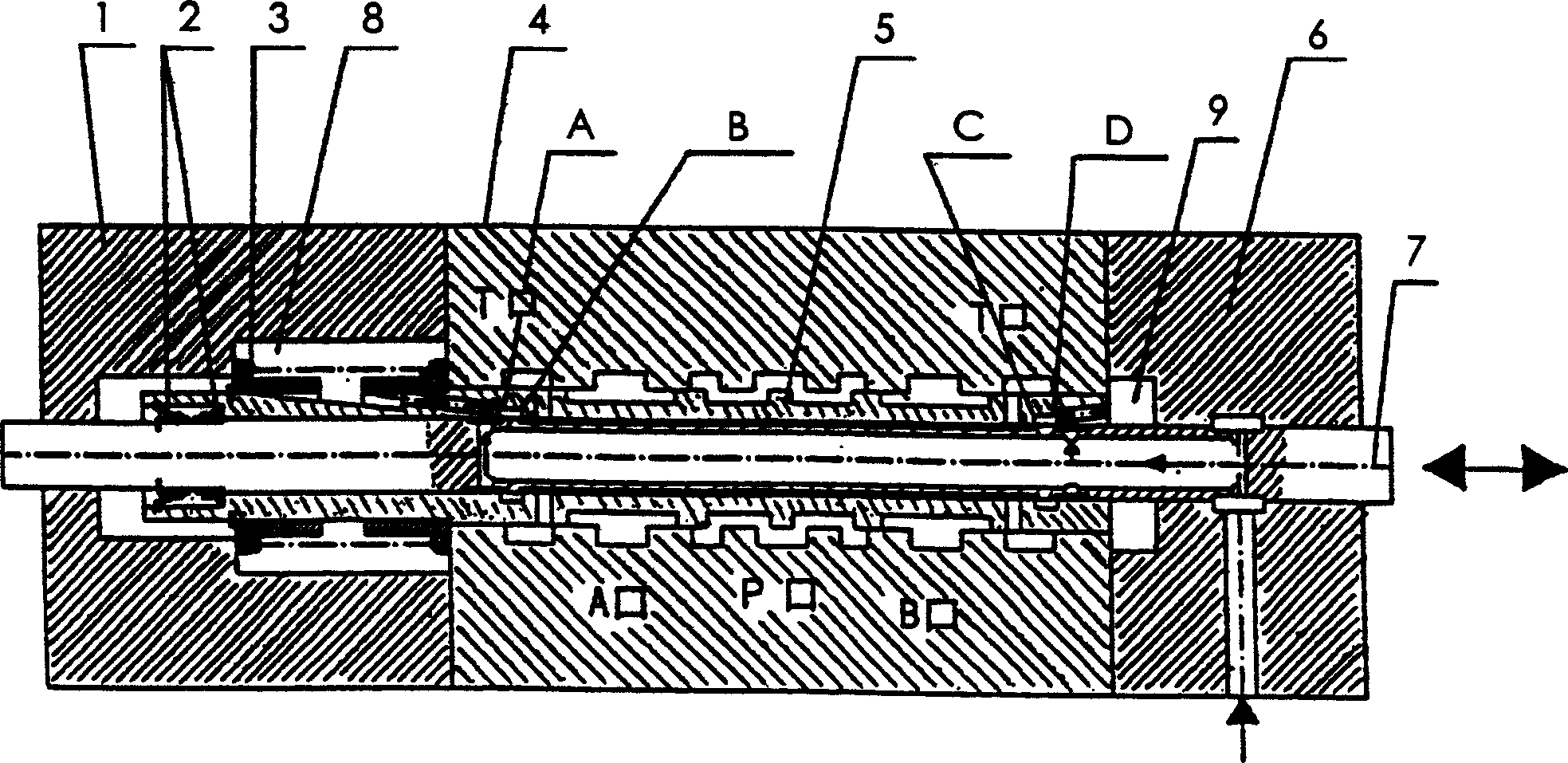

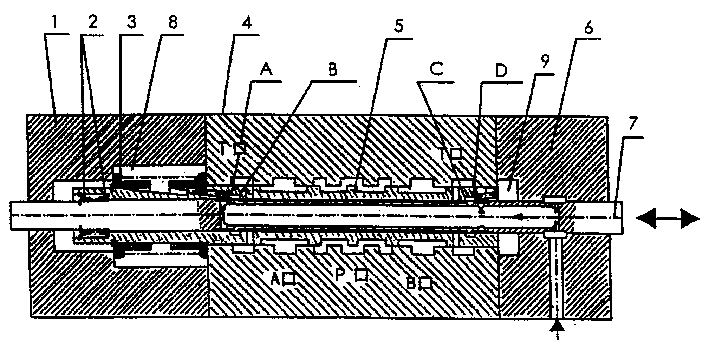

[0010] Such as figure 1 Shown, the present invention is made up of left end cover 1, control spool balance spring 2, main valve balance spring 3, main valve body 4, main spool 5, right end cover 6 and control spool 7. The left end cover 1 is connected and fixed on the main valve body 4 , and is sealed with the main valve body 4 to form a left control chamber 8 . There is a circular hole coaxial with the circular hole of the main valve body and with a diameter equal to the diameter of the control valve core 7 on the side, and determines the neutral position of the main valve. The right end cover 6 is connected and fixed on the valve body, and is sealed with the valve body 4 to form a right control chamber 9 . There is a round hole coaxial with the round hole of the main valve body and the diameter is equal to the diameter of the control valve core 7 on the side, and an annular groove with a certain width is arranged on the round hole, and an oil port is connected to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com