Tyre bead with extended mobility

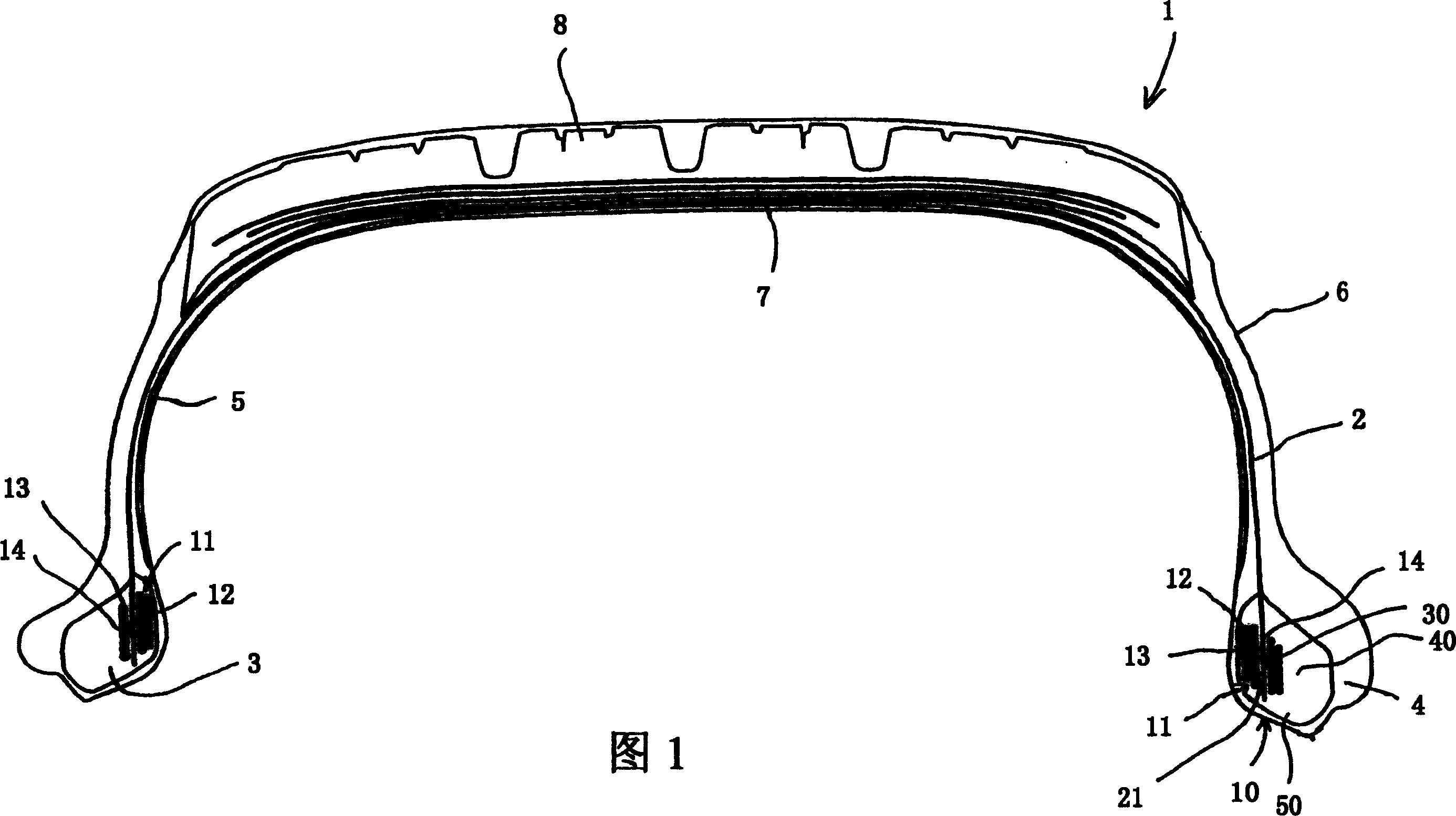

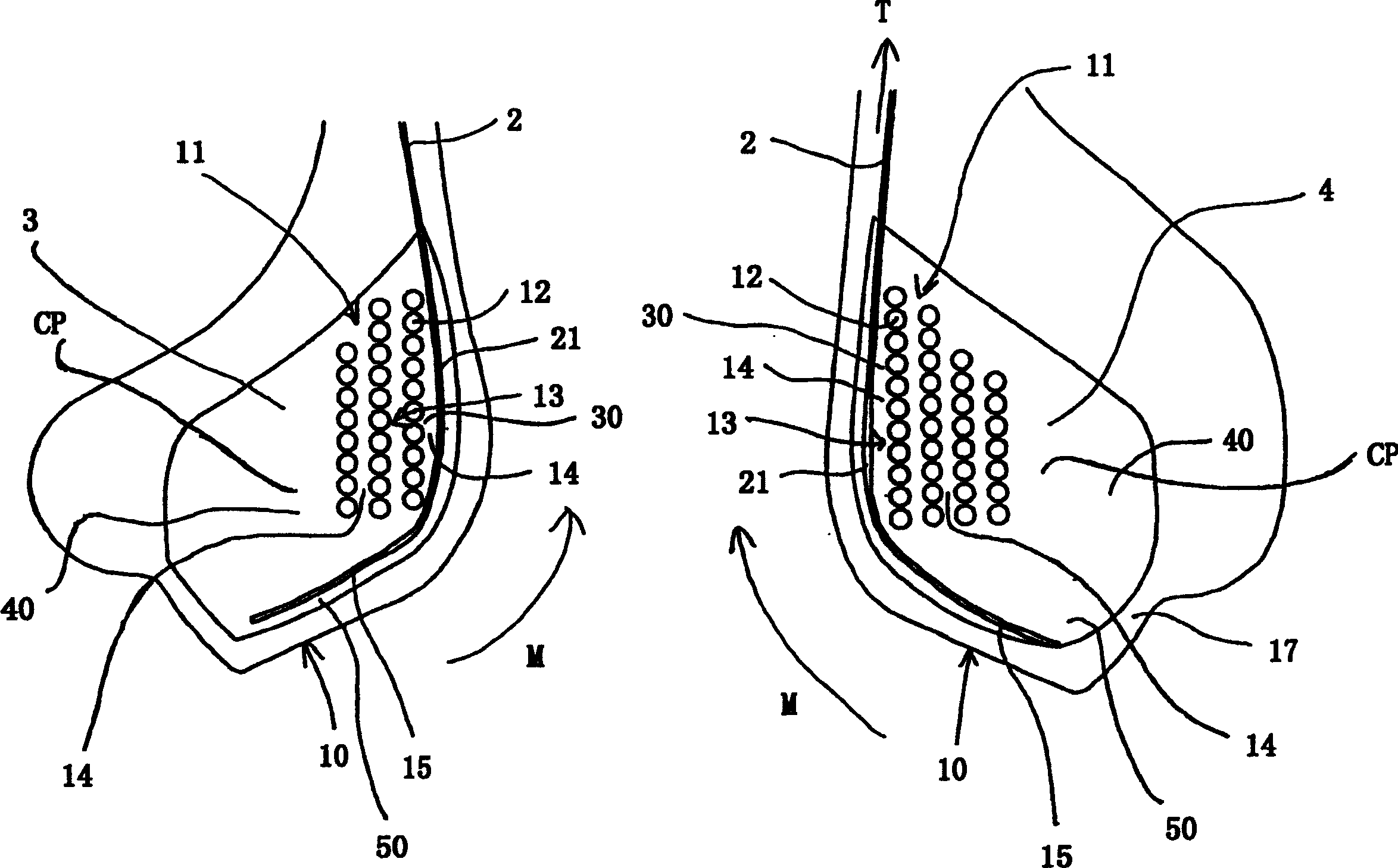

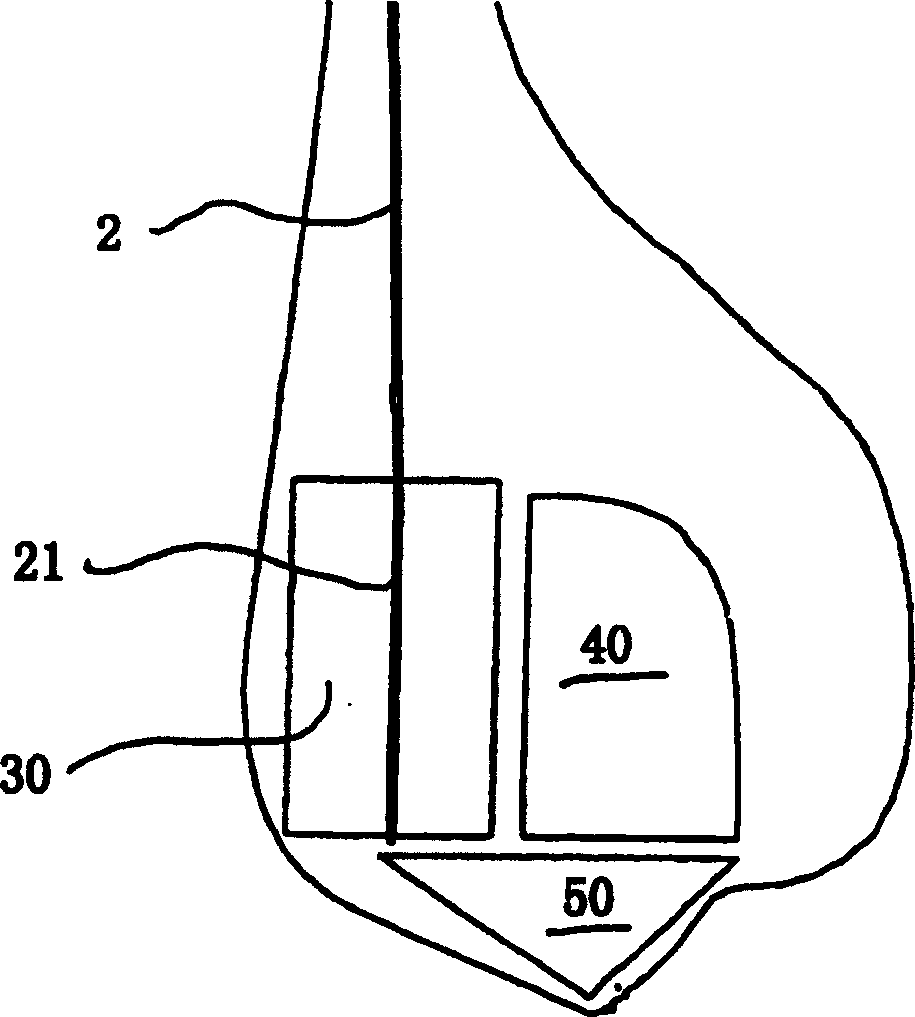

一种轮胎、胎圈的技术,应用在轮胎零部件、胎沿、车轮等方向,能够解决轮胎安装/拆卸困难等问题,达到良好轴向保持、优化设计和制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In this specification, the term "cord" generally refers to monofilaments and multifilaments or assemblies, such as steel cords, plied wires or any equivalent type of assembly, regardless of the material and treatment of these cords. They may be surface-treated, coated or pre-finished, for example to aid in bonding with rubber.

[0097] On the other hand, "radial structure" is understood as an arrangement at 90°, but according to custom, it can also be an angle close to 90°.

[0098] As is known, generally the carcass ply is inverted about a bead wire. The bead wire then acts to fix the carcass. In this way, in particular, it withstands the tensile forces that occur on the carcass cords, for example under the action of inflation pressure. The structures described in the literature are able to guarantee a similar fixing effect. It is also known to ensure the clamping of the bead on the rim with bead wires of conventional form. The constructions described in the litera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com