Semi-synthesized olefins conversion catalyst containing modified nano aluminium oxide

A nano-scale, alumina technology, applied in physical/chemical process catalysts, molecular sieve catalysts, catalytic cracking, etc., can solve problems such as limiting the processing capacity of catalytic cracking units, gasoline selectivity decline, and zeolite crystal destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

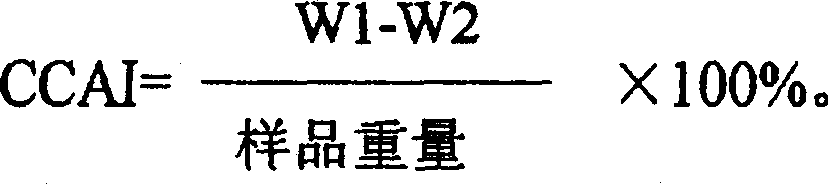

Method used

Image

Examples

example 1

[0023] Add 65L of mixed solution of cerium chloride, zirconium chloride and magnesium chloride to 23529g, n-m alumina. The content of cerium chloride in the solution is 21.5g / l, the concentration of zirconium chloride is 12g / l, and the concentration of magnesium chloride is 142g / l. Soak for 1.5 hours , and then filtered and dried to obtain modified nano-alumina A, which contains 4.0% Ce, 2.0% Zr, and 1% Mg.

example 2

[0025] To 23529g n-mAl 2 o 3 Add 65L of a solution containing 42.5g / L of cerium chloride, soak for 1.5 hours, filter, dry, and roast at 400°C for 2 hours, then add 65L of a solution containing 12.8g / l of magnesium sulfate, soak for 1.5 hours, filter, drying. The resulting modified n-mAl 2 o 3 The Ce content in B is 8.0%, and the Mg content is 3.5%.

example 3

[0027] To 23529g n-mAl 2 o 3 Add 80L of a solution containing 42.5g / L of zirconium sulfate solution, soak for 1.5 hours, filter and dry, and the obtained modified nano-alumina C has a Zr content of 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com