Plasma display panel

A technology for display panels and phosphors, which can be applied to alternating current plasma display panels, gas discharge electrodes, solid cathode components, etc., and can solve problems such as the reduction of color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

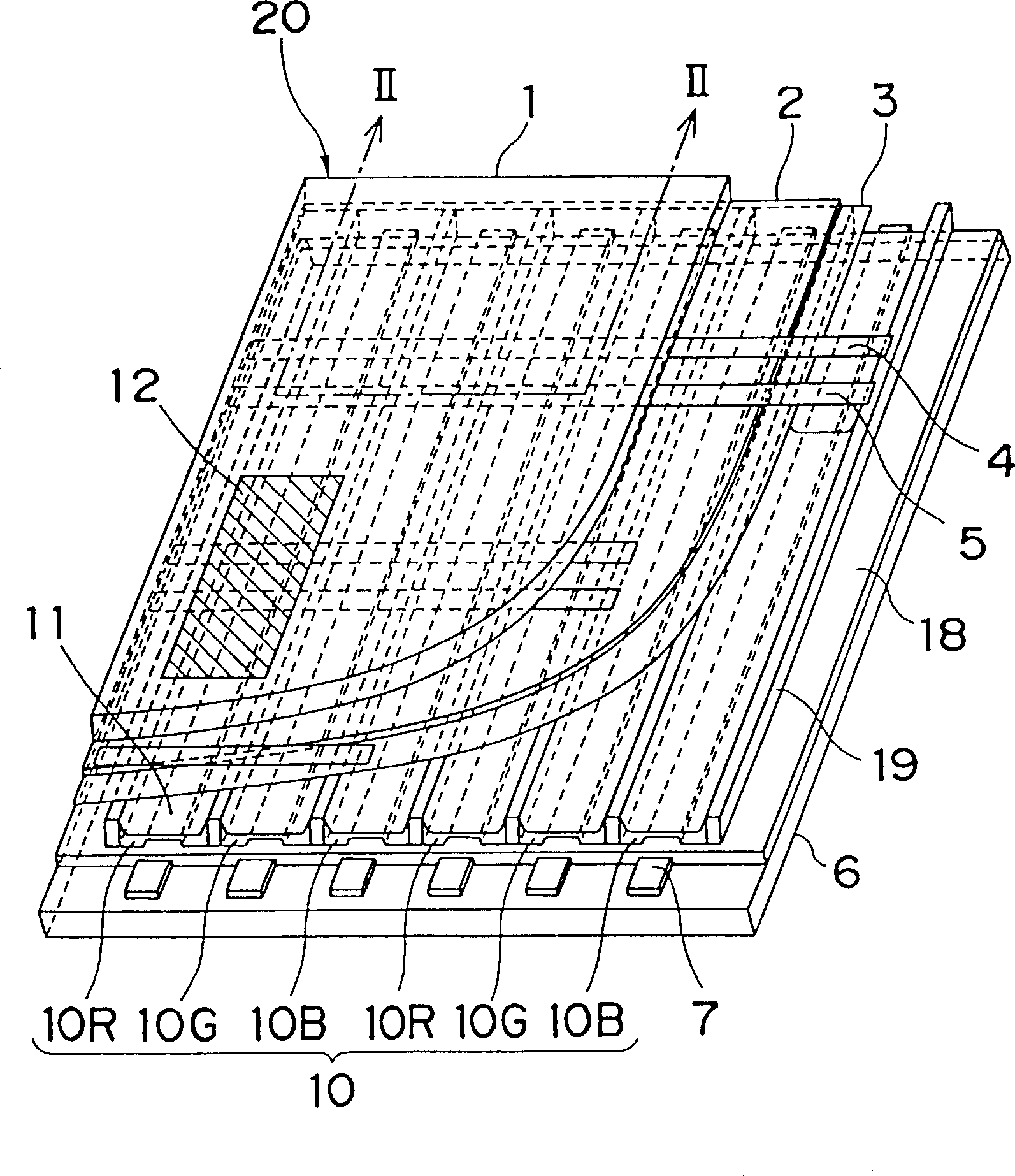

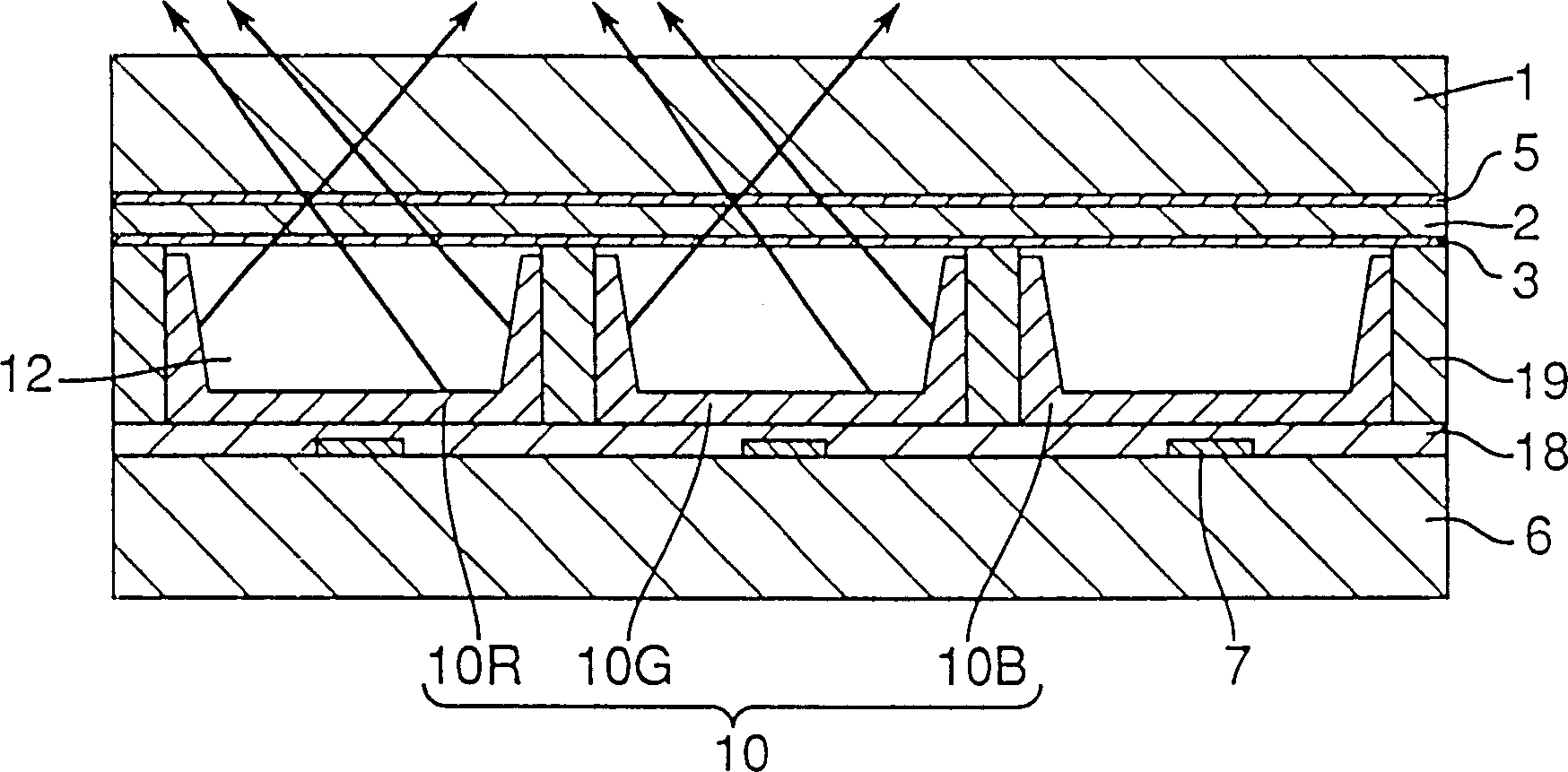

[0023] Hereinafter, an embodiment of the plasma display panel of the present invention will be described in detail with reference to the accompanying drawings.

[0024] figure 1 is an enlarged perspective view of a portion of a plasma display panel of the present invention, generally indicated by reference numeral 20 . As shown in the figure, the structure of the display panel 20 of the present invention is the same as Figure 5 The structure of the plasma display panel 20' shown in is basically the same. Therefore, the description of the structure of the plasma display panel 20 is omitted, and in figure 1 and Figure 5 The same parts and accessories having the same function in have the same reference number.

[0025] The difference between the plasma display panels 20 and 20' lies in the materials of the base glass layer and the ribs. Specifically, although the material of the base glass layer 8 and the ribs 9 of the plasma display panel 20' in the prior art has a white ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com