Process for synthesizing biphenylamine from phenylamine by adding nitrogen gas to reactor

A diphenylamine method and reactor technology, which are applied in the preparation of amino compounds from amines, the preparation of amino-substituted hydrogen atoms, and organic chemistry, can solve the problems of high cost and incomplete reduction of hydrogen consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

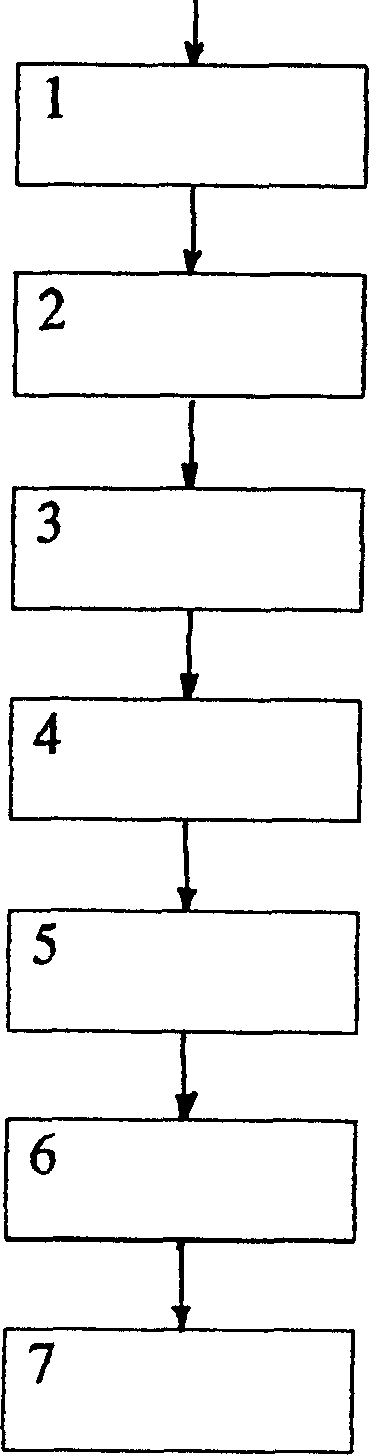

Image

Examples

Embodiment Construction

[0007] Aniline is determined by the volume of the aniline metering tank (v=6m 3 ), a metering pump (piston pump), with a flow rate of 2t / h after metering, through a nitrogen buffer bag (P=2.0MPa, V=0.3m 3 ) into the aniline heating 2, the raw material product heat exchanger is preheated, and then heated to 340 ° C by an electric heater and enters the reactor. Nitrogen is added to the reactor. The pressure in the reactor is 2MPa, and 10m of catalyst 3 The space velocity ratio with aniline is 0.2 / h, and the temperature is 340°C. The model of the catalyst is FD-20, which is produced by Fushun Petrochemical Research Institute. The material at the outlet of the reactor is lowered to below 150°C through the raw material product heat exchanger, and then decompressed to below 0.1MPa, and then enters the gas-liquid separator 4. High-temperature separator, the gas phase in the high-temperature separator is cooled to below 40°C by the condenser and enters the low-temperature separator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com