Eddy current inspection technique

A current and eddy current technology, applied in the direction of electromagnetic measuring devices, electric/magnetic thickness measuring, measuring devices, etc., can solve the problems of local wall thickness reduction, inability to detect corrosion points, size increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

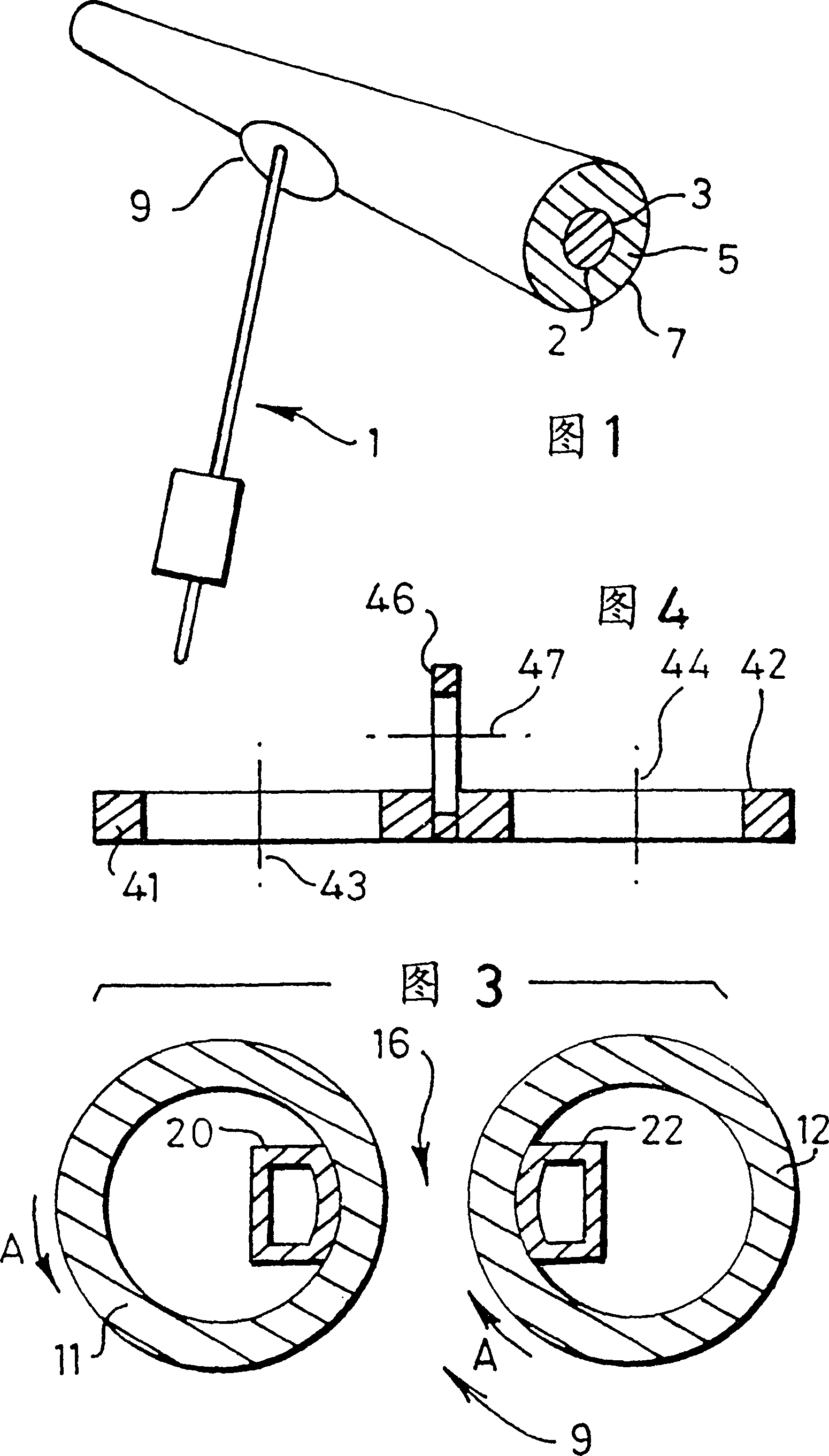

[0024] In the following description, the same reference numerals denote the same parts.

[0025] FIG. 1 shows a probe 1 for detecting an object made of conductive material. This probe 1 can be used to detect the thickness of the pipe wall 2 on the pipe 3 to detect the corrosion state on the pipe wall 2. Corrosion may occur at the outside surface or inside surface of the pipe wall 2. A layer of insulating material 5 is arranged around the tube 3, and a sleeve 7 made of thin metal steel is covered on the outside of the insulating material layer 5. The probe 1 includes a device 9 for detecting an object made of conductive material, and the device 9 is held at a position opposite to the outer surface of the steel sleeve 7 during normal operation.

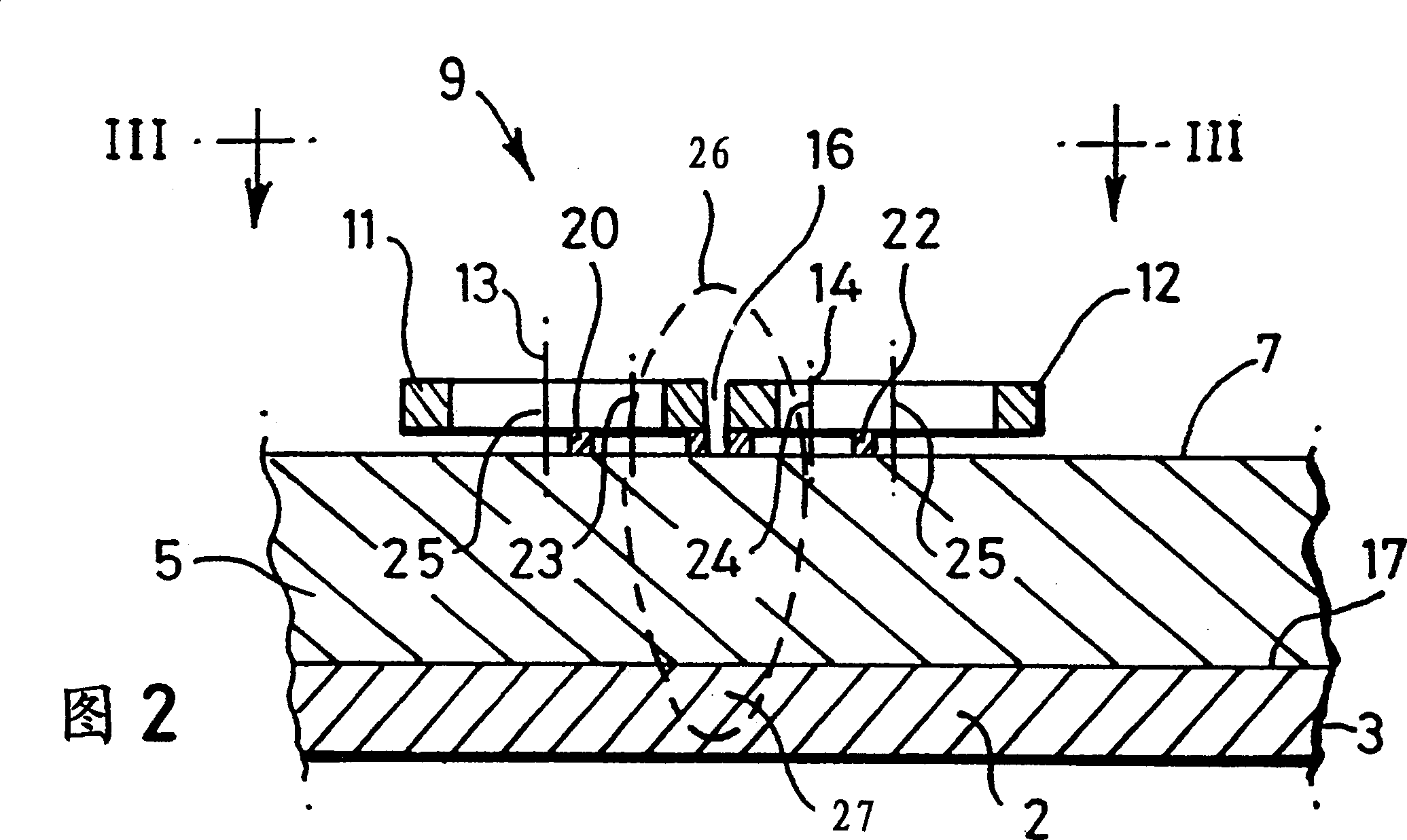

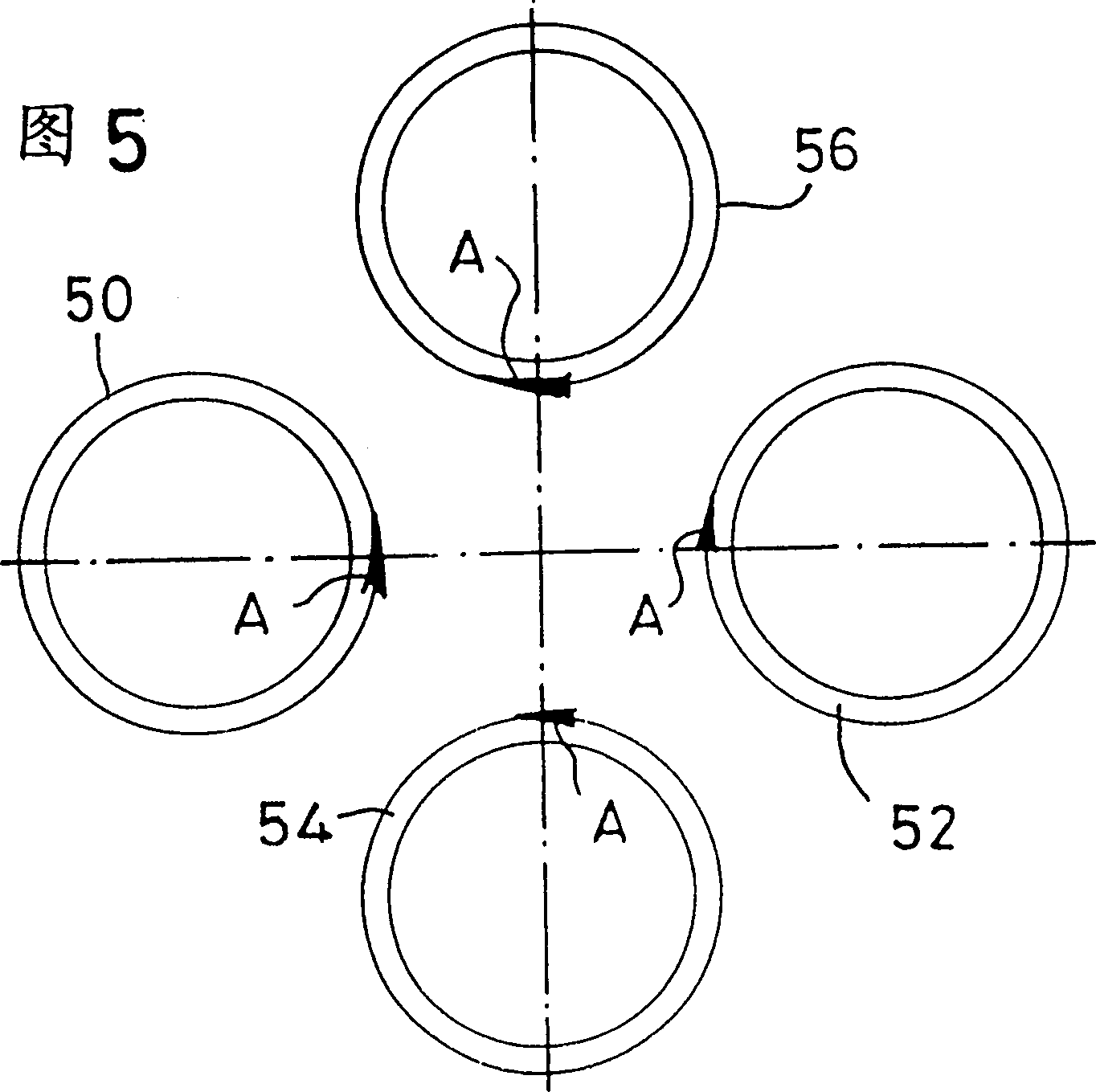

[0026] As shown in Figures 2 and 3, the device 9 for detecting objects made of conductive materials includes a non-steady-state signal transmitter for generating a non-steady-state electromagnetic field in an object such as a tube wall 2, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com