Liquid container, Liquid supply system

A liquid container and liquid supply technology, applied in the direction of printing, etc., can solve the problems of thickening of the inner wall and increase of the bonding layer, and achieve the effect of reducing the buffer space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

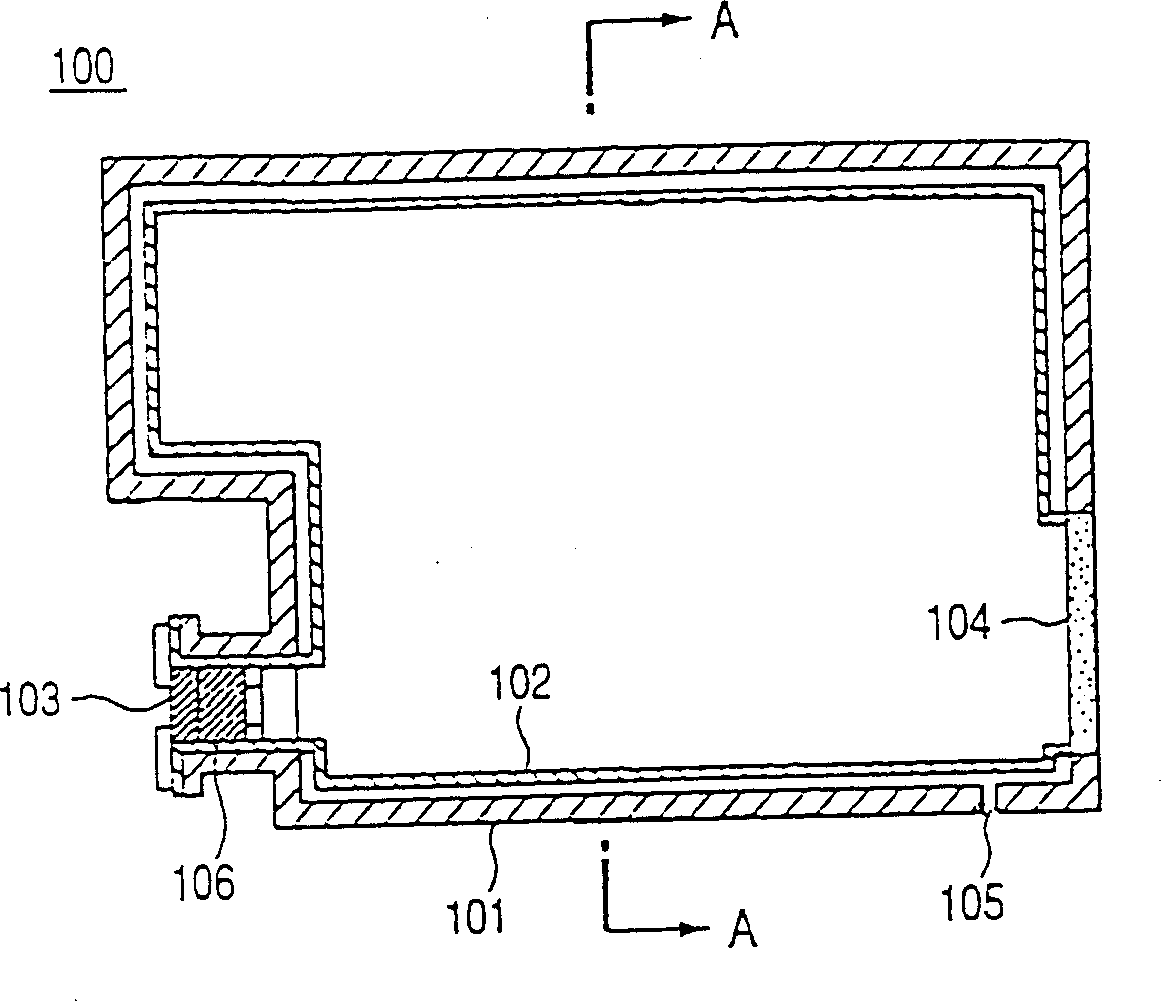

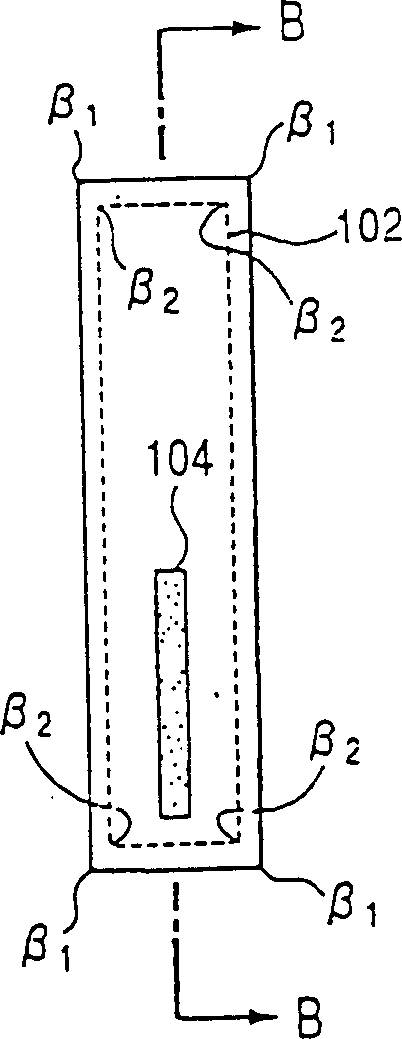

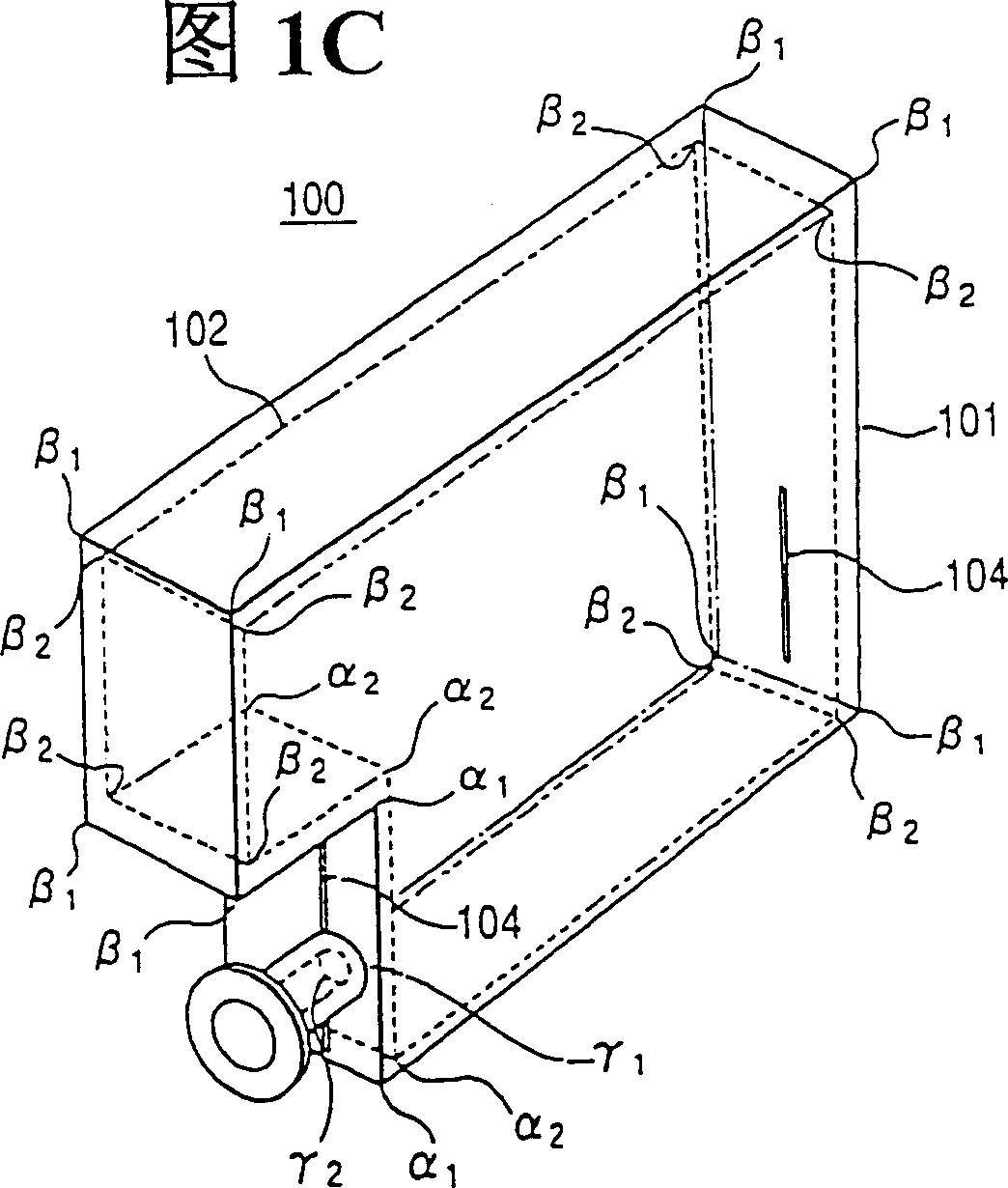

[0061] Figure 1A The inner wall 102 of the ink cartridge 100 shown to 1C is composed of a different material. According to the materials applicable to the inner wall, the characteristics of the negative pressure are tested through the change of temperature.

[0062] The results of the inspection are shown in the following Table 1, wherein the capacity of the ink cartridge is 12CC; the thickness of the inner wall 102 is 200um (hereinafter referred to as the maximum thickness); the width of the ink cartridge is about 10m; and the outside temperature is 5°C and 35°C.

[0063] Material

5℃

35℃

Changes in negative pressure characteristics

PET

-95mmAq

-96mmAq

good

APL

-115mmAq

-110mmAq

good

HDPE

(comparative example)

-140mmAq

-30mmAq

bad

[0064] As can be seen from Table 1 above, when the inner wall is composed of PET (polyethylene terephthalate) or APL (Apel: registered trademark by...

no. 2 example

[0073] The outer wall 101 and inner wall 102 of the ink cartridge can be made of different materials, respectively. Furthermore, the inner wall 102 can be constructed by laminating several sheets of different materials.

[0074] The inventor has prepared one such as structure embodiment A (see Figure 10 ) ink cartridge, by using 1000 μm thick PP (polypropylene) to construct the outer wall 101, while using EVOH (EVH saponified product (ethylene ethyl acetate)) with a thickness of 10-15 μm to construct the outermost layer 102a of the inner wall, using The middle sheet layer 102b of the inner wall is constructed with APL having a thickness of 200-230 μm and a mixed resin containing a functional adhesive resin therein, and the innermost sheet layer 102c of the inner wall is constructed with HDPE (high-density polyethylene) having a thickness of 60 μm, and they are Rolled together to form the inner wall. The inner wall thickness of Structural Example A is about 300 μm.

[0075]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com