Pressure cavity

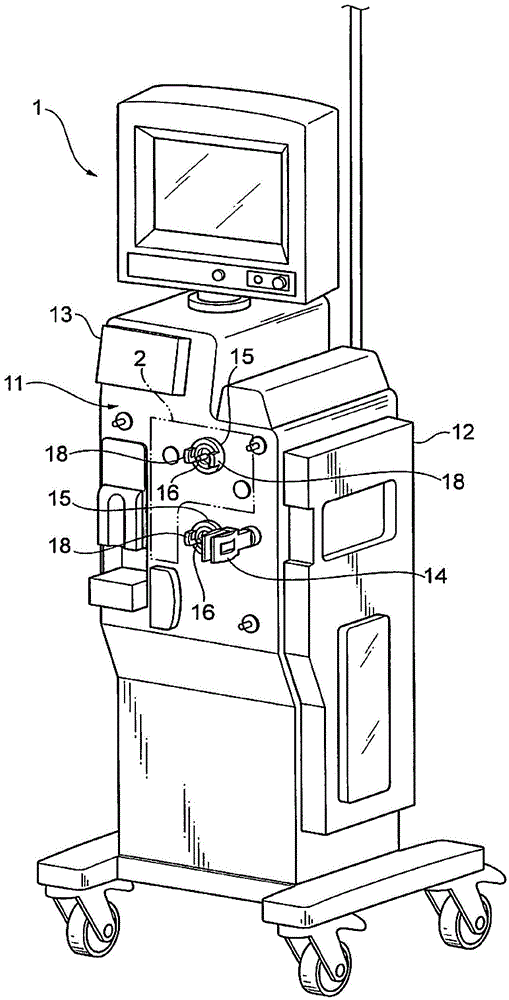

A technology of pressure chamber and pressure sensor, which is applied in the direction of pharmaceutical equipment, other medical equipment, dialysis systems, etc., can solve the problem of unstable negative pressure characteristics, achieve stable negative pressure characteristics, improve detection accuracy, and prevent negative pressure characteristics Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

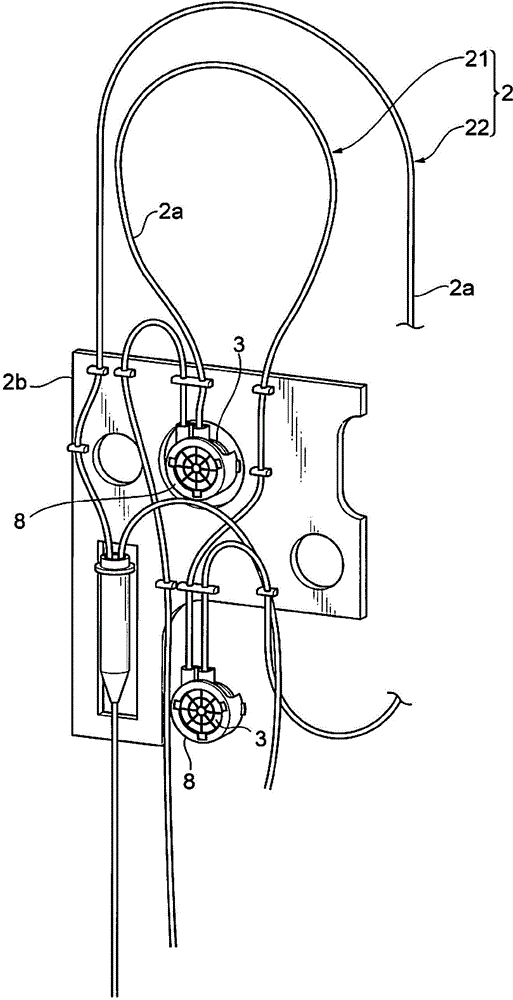

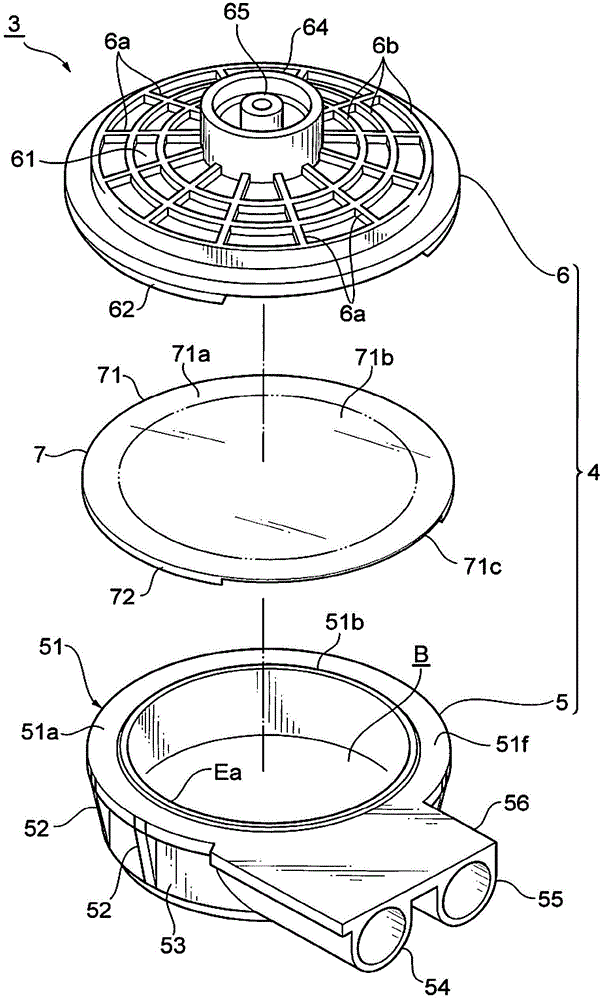

[0045] Next, the pressure chamber 3 of the first embodiment of the present invention will be described. Such as Figure 3 ~ Figure 7 As shown, the pressure chamber 3 has: a container body 4; and a diaphragm 7, which is located in the container body 4, is used to partition the blood chamber B and the air chamber A, and transmit the blood chamber B to the air chamber A through elastic deformation. Pressure.

[0046] The container main body 4 includes a main body casing 5 and a lid casing 6 for blocking the opening of the main body casing 5. In this embodiment, blood Ba is exemplified as a liquid that is required to avoid contact with air, and the main body housing 5 is an example of a liquid chamber container that forms a blood chamber (liquid chamber) B. In addition, the lid housing 6 is an example of a gas chamber container that is coupled to the main body housing 5 to form an air chamber (gas chamber) A communicating with the pressure sensor 1 a.

[0047] The main body housing ...

no. 2 Embodiment approach )

[0087] Next, refer to Picture 11 The pressure chamber 3A of the second embodiment of the present invention will be described. The pressure chamber 3A of the second embodiment has the same members and structure as the pressure chamber 3 of the first embodiment. Therefore, in the following description, the same members and structures are denoted by the same reference numerals as those of the pressure chamber 3 of the first embodiment, and detailed description is omitted, and the description will be centered on the differences.

[0088] Such as Picture 11 As shown, the pressure chamber 3A has: a container body 4A; and a diaphragm 7A in the container body 4A, which separates the air chamber A and the blood supply Ba (refer to Figure 8 ) The flowing blood chamber B is divided, and the internal pressure of the blood chamber B is transferred to the air chamber A through elastic deformation. Furthermore, the container main body 4A includes a main body casing (liquid chamber side conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com