Method for combining multiple brow-streaking needles into a whole

An eyebrow tattooing needle and integrated technology, which is applied in the field of multi-needle group positioning and shaping of eyebrow tattooing needles, can solve the problems of difficult alignment of needles, time-consuming assembly and processing, and high production costs, so as to reduce human error, ensure safety and sanitation, and manufacture The effect of program shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

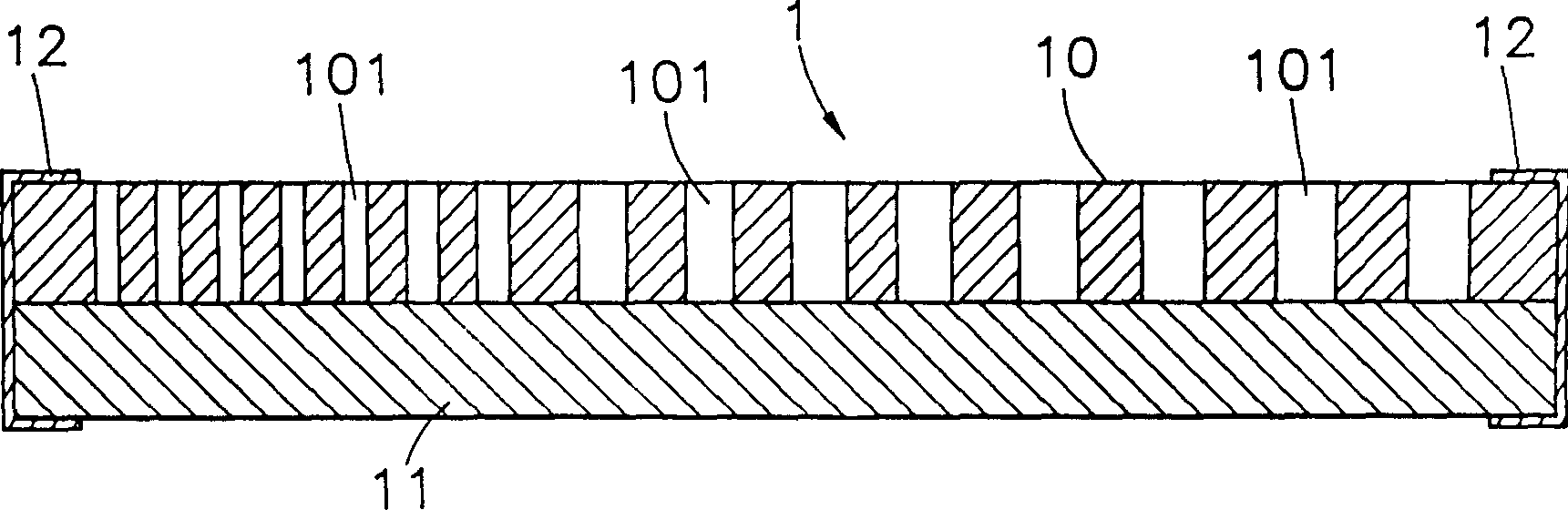

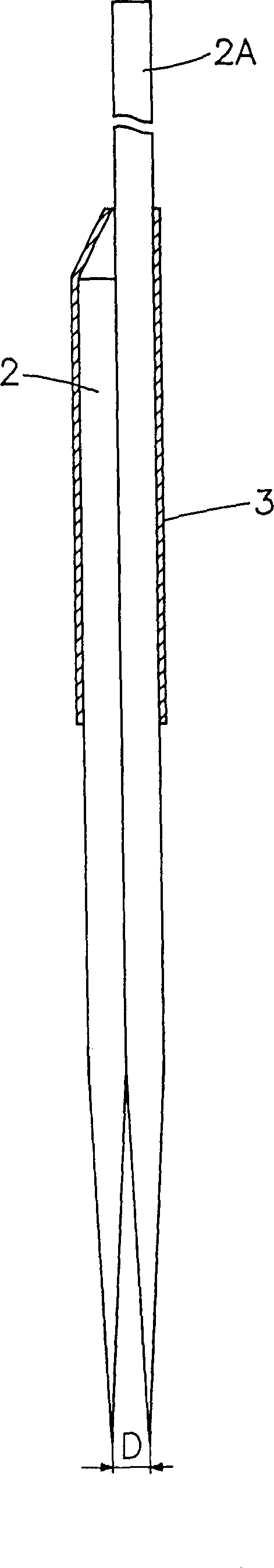

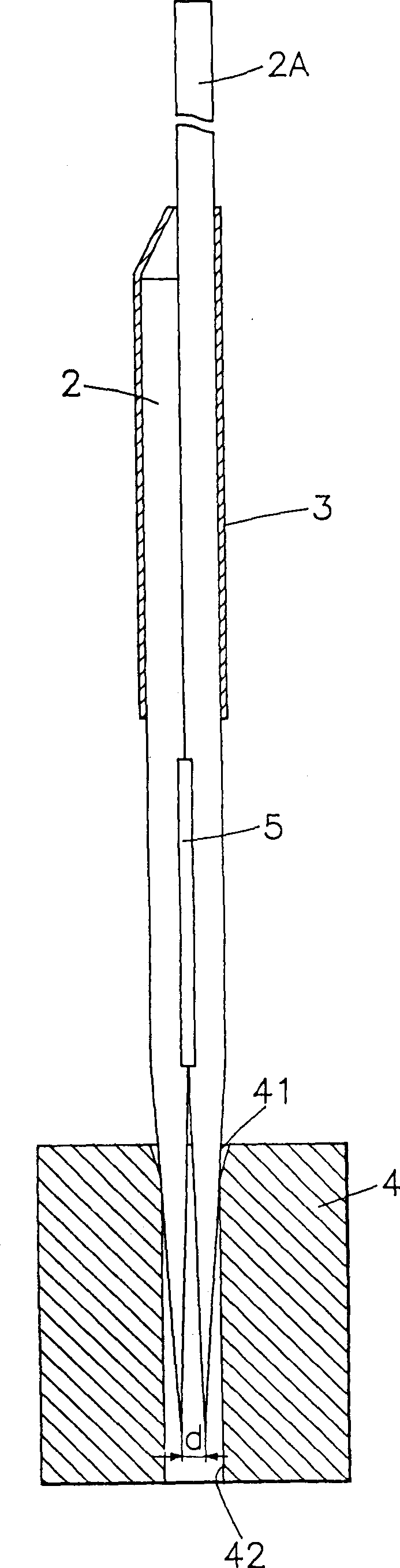

[0028] see figure 1 And Fig. 2, the method for integrating multiple needles of tattoo needles provided by the present invention is mainly to place a heat-resistant plate 10 (such as phenolic plastic bakelite or other materials suitable for the present invention) with a plurality of through holes 101 On the plane heat-resistant base pad 11 (such as glass or other materials suitable for the present invention), its corners around it are clamped with clamps 12 to form a fixed plate group 1 (such as figure 1 shown), in order to put several (more than one needle) short needles 2 (Figure 2 is an embodiment of a single short needle) into the through hole 101 to keep it upright, and put a heat shrinkable sleeve 3 into the short needle The other end of the needle set is not bound, and then insert a long needle 2A, so that the needle tips of the long and short needles are flush with the flat heat-resistant bottom pad 11, and then move it into the oven to heat to make the heat-shrinkable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com