Desulfurization system multi-working-condition prediction method based on extreme learning machine

A technology of extreme learning machine and desulfurization system, which is applied in the field of multi-condition prediction of desulfurization system based on extreme learning machine, which can solve the problems of large delay and inability to accurately predict outlet concentration, so as to reduce the influence of delay time and improve prediction efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0084] The description in this section is only for a few typical embodiments, and the present invention is not limited to the scope of the description of the embodiments. Combinations of different embodiments, replacement of some technical features in different embodiments, and replacement of same or similar prior art means with some technical features in the embodiments are also within the scope of description and protection of the present invention.

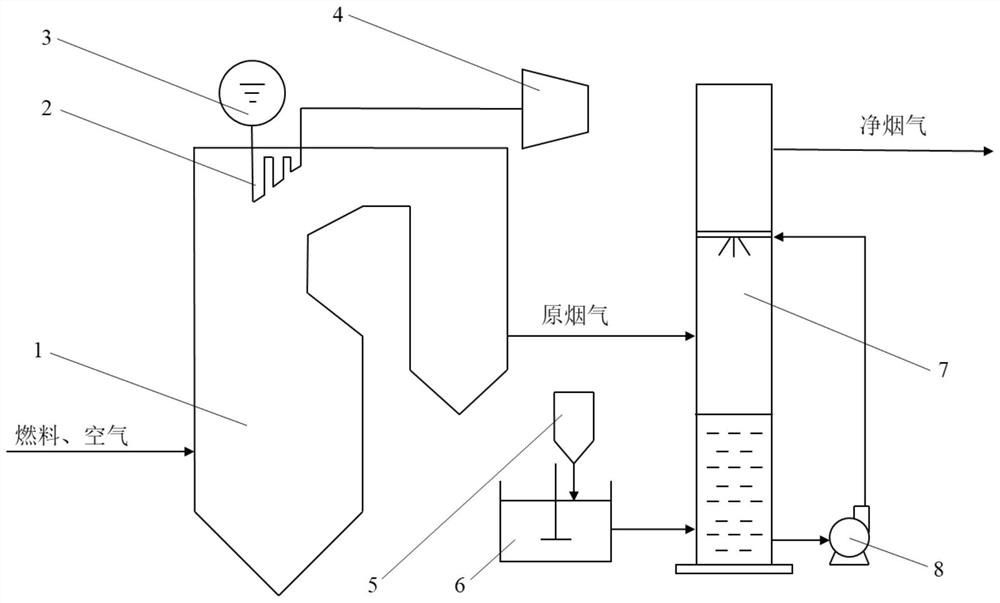

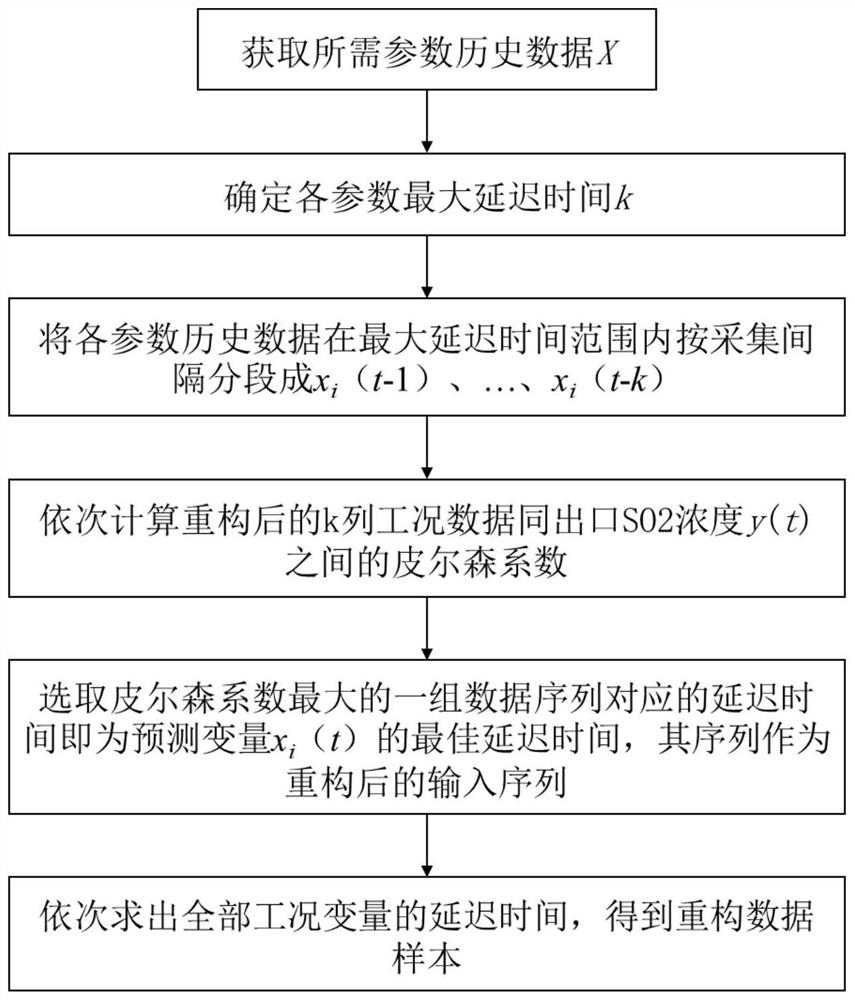

[0085] like figure 1 Shown is a process flow diagram of a thermal power plant wet desulfurization process to which this technical solution is applicable. The states o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com