Method for setting adjustable high-precision quantitative wine pumping device

A high-precision and adjustable technology, applied in the direction of flow control of electrical devices, comprehensive factory control, etc., can solve the problems of inconsistent product quality, large measurement error, small finished product error, etc., to solve the problem of discreteness and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

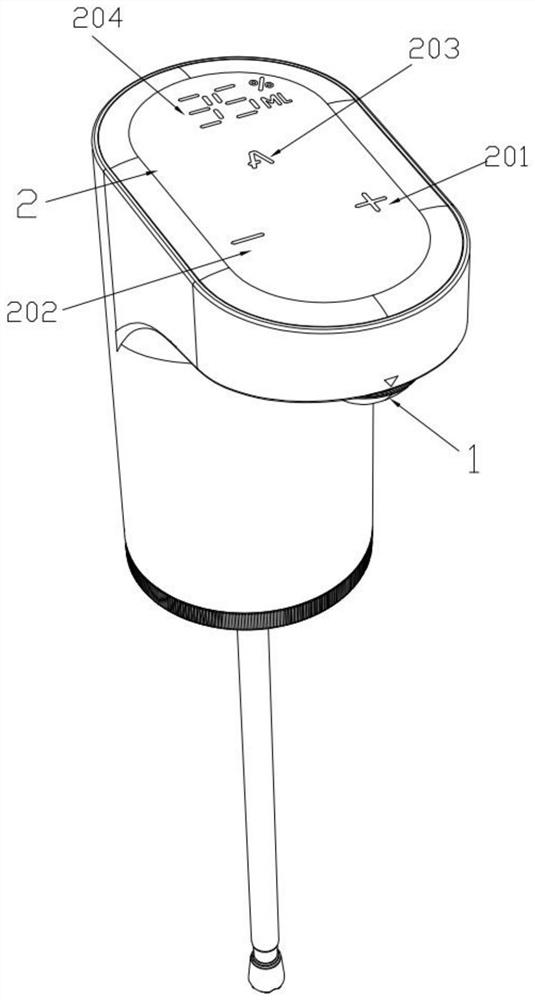

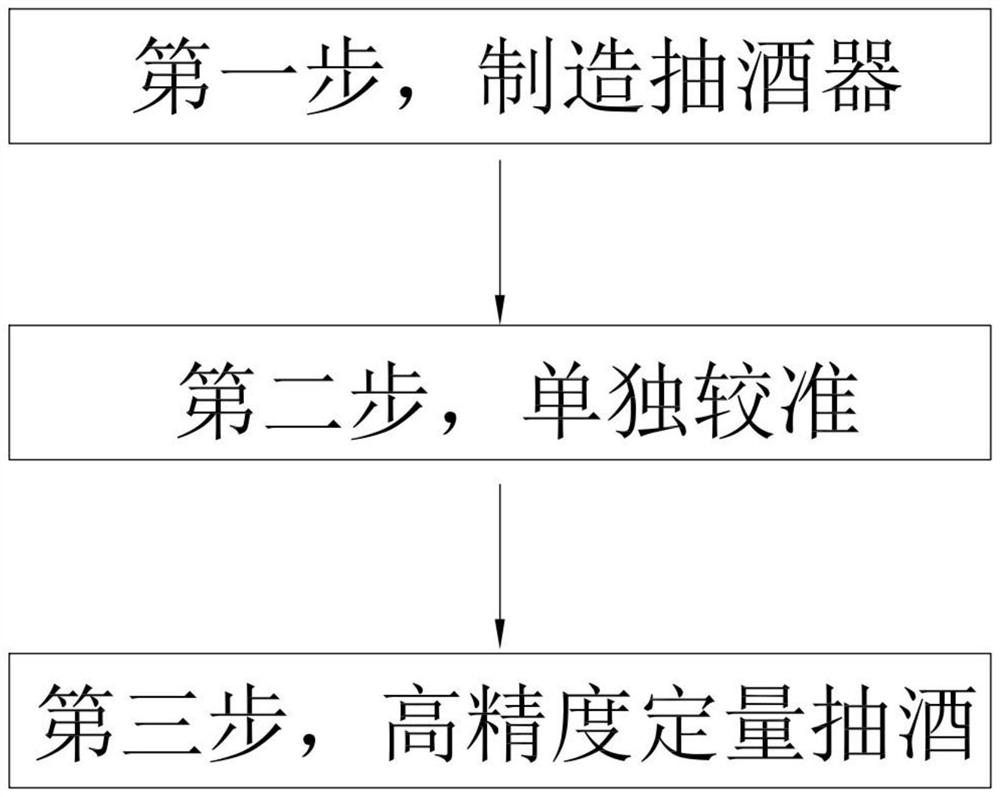

[0022] In this embodiment, refer to figure 1 and figure 2 , the specific implementation of the adjustable high-precision quantitative wine extractor setting method, comprising the following steps:

[0023] The first step is to manufacture the wine pump. The wine pump includes a pump, a main control chip, a power supply, a water outlet 1 and a main control panel 2. The main control panel 2 includes a display screen 204 and control buttons. The control buttons are used to set the output. The water volume, the display screen 204 is used to display the value of the set water output, and the control buttons include a capacity increase button 201, a capacity decrease button 202 and a sober button 203; the second step is to calibrate independently and enter the formula into the main control chip The wine pump is energized before leaving the factory. By controlling the operation of the pump of the wine pump, the running time T of the pump and the volume Q of the wine extracted duri...

Embodiment 2

[0027] In this embodiment, refer to figure 1 and figure 2 , the specific implementation of the adjustable high-precision quantitative wine extractor setting method, comprising the following steps:

[0028] The first step is to manufacture the wine pump. The wine pump includes a pump, a main control chip, a power supply, a water outlet 1 and a main control panel 2. The main control panel 2 includes a display screen 204 and control buttons. The control buttons are used to set the output. Water volume, the display screen 204 is used to display the value of the set water output, and the control buttons include a capacity increase button 201, a capacity decrease button 202 and a sober button 203;

[0029] The second step is to calibrate separately and enter the formula into the main control chip The wine pump is energized before leaving the factory. By controlling the operation of the pump of the wine pump, the running time T of the pump and the volume Q of the wine extracted d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com