Excavator weighing method

An excavator and weighing technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, weighing, etc., can solve problems such as operator fluctuations, material property differences, and center of gravity differences. To achieve the effect of eliminating the influence of accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

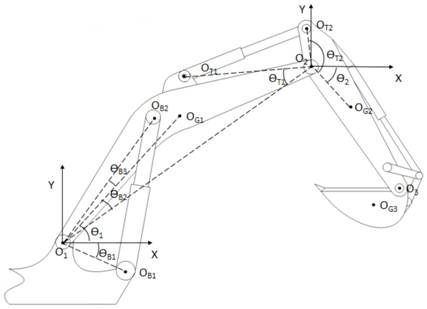

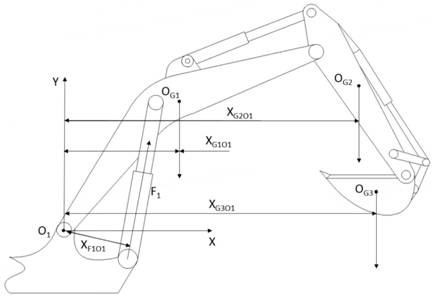

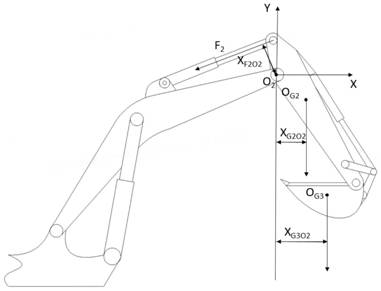

[0065] The implementation of the technical solution will be further described in detail below with reference to the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0066] Concept of the present invention: In this scheme, the bucket containing the material is regarded as a whole, and a center of gravity O is assumed for the whole in the space coordinates. G3 ; At a specific moment when the working device is stationary, use the known quantity and the collected quantity to simultaneously list the moment balance equation for two different points, and eliminate the assumed center of gravity O after the simultaneous combination G3 The effect on the solution for the weight G of the bucket loaded with material.

[0067] like Figures 1 to 3 As shown, an excavator weighing method is characterized in that, it includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com