Load cell assembly and weighing method

A technology of load cells and components, applied in weighing equipment, instruments, weighing and other directions using elastically deformable parts, can solve problems such as inapplicability and sensor system-level output errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

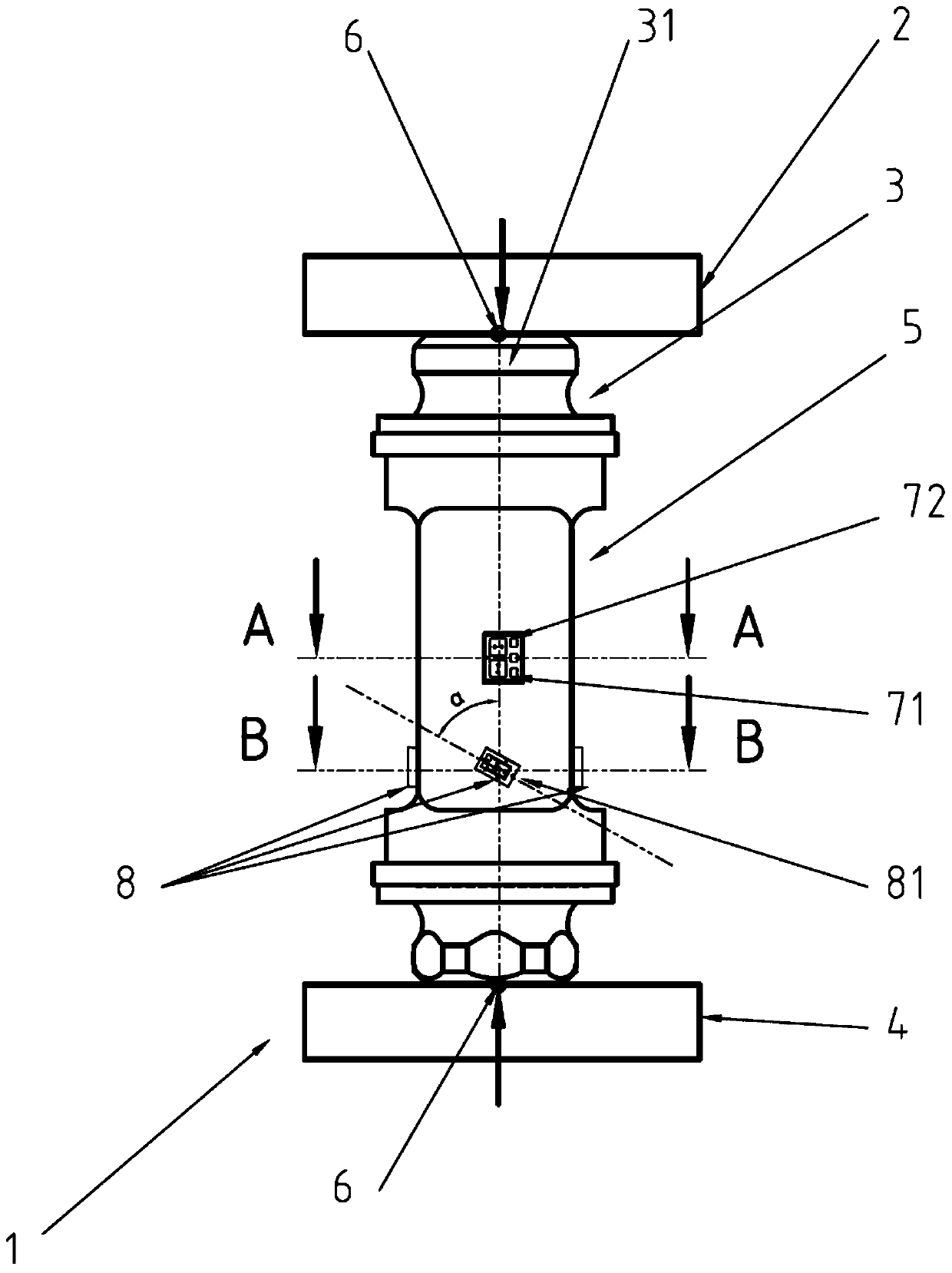

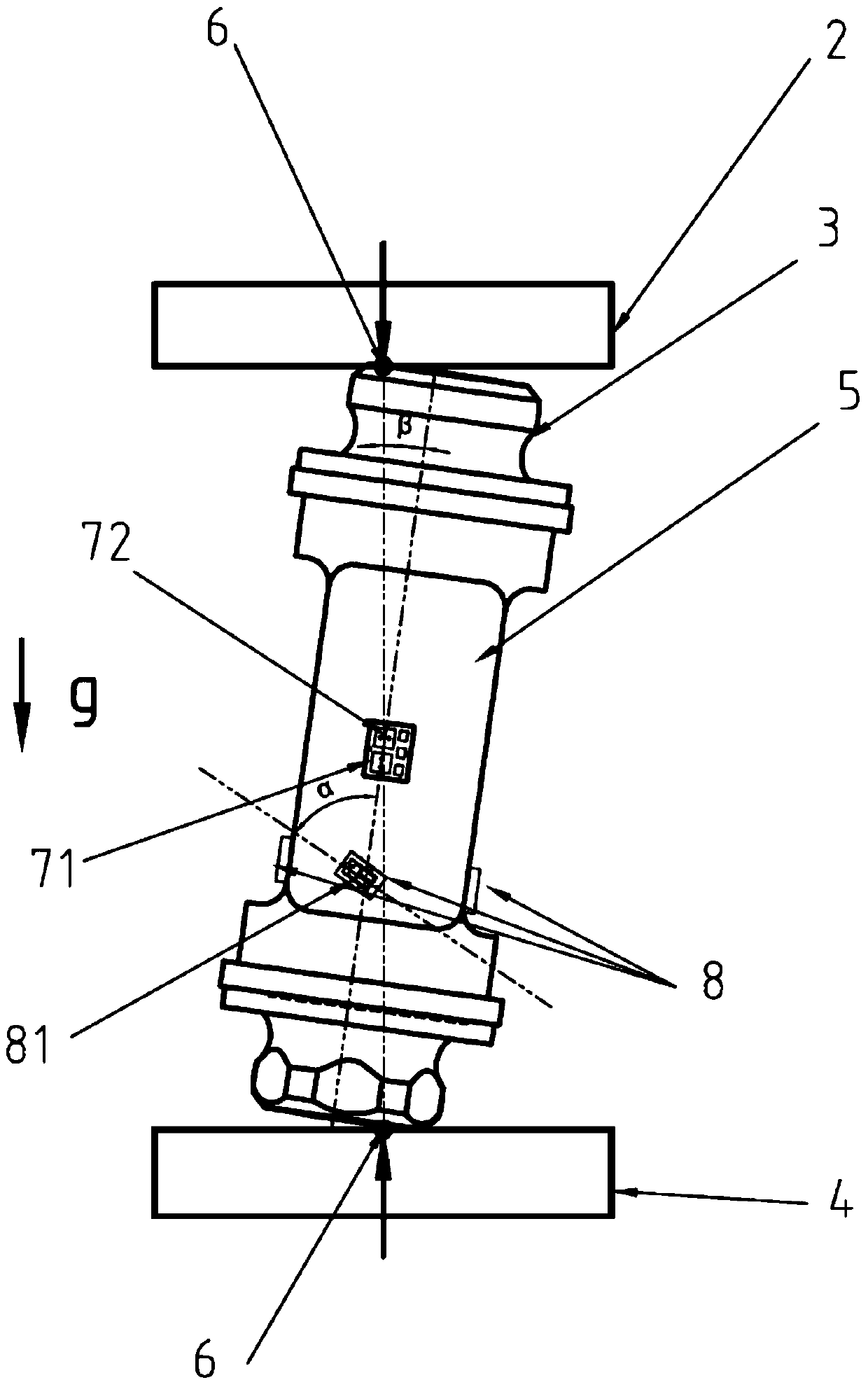

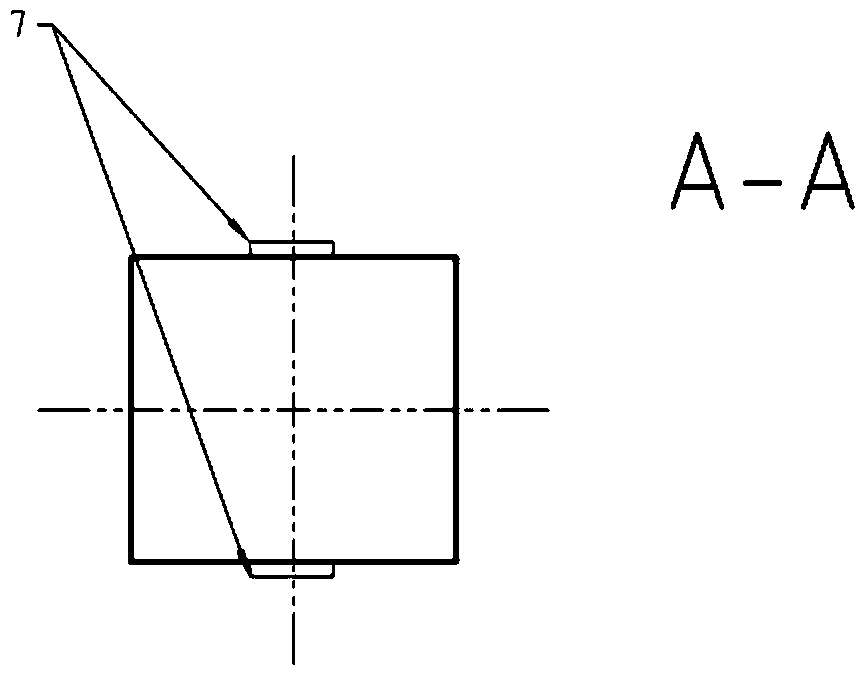

[0035] refer to Figure 1 to Figure 4 , the load cell 1 provided by the present invention is preferably a column load cell with a rocking column structure. The load cell 1 includes an upper pressure bearing surface 2, an elastic element 3, a lower pressure bearing surface 4, a primary strain unit and a secondary strain unit. The lower pressure bearing surface 4 is opposite to the upper pressure bearing surface 2 . The elastic element 3 has a central axis 31 located between the upper bearing surface 2 and the lower bearing surface 4 . The upper pressure bearing surface 2 and the lower pressure bearing surface 4 of the load cell 1 respectively have a contact portion 6 in contact with the elastic element 3 , the position of which is related to the processing accuracy, inclination angle and radius of the ball head of the elastic element 3 . Ideally, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com