Integral axle weight scale for road vehicle and mounting method thereof

An all-in-one, vehicle technology, applied in special scales, measuring devices, instruments, etc., can solve the problems of low dynamic weighing accuracy, short transformation period, less maintenance workload, etc., so as to reduce equipment maintenance costs and reduce the height of the weighing platform. , the effect of safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

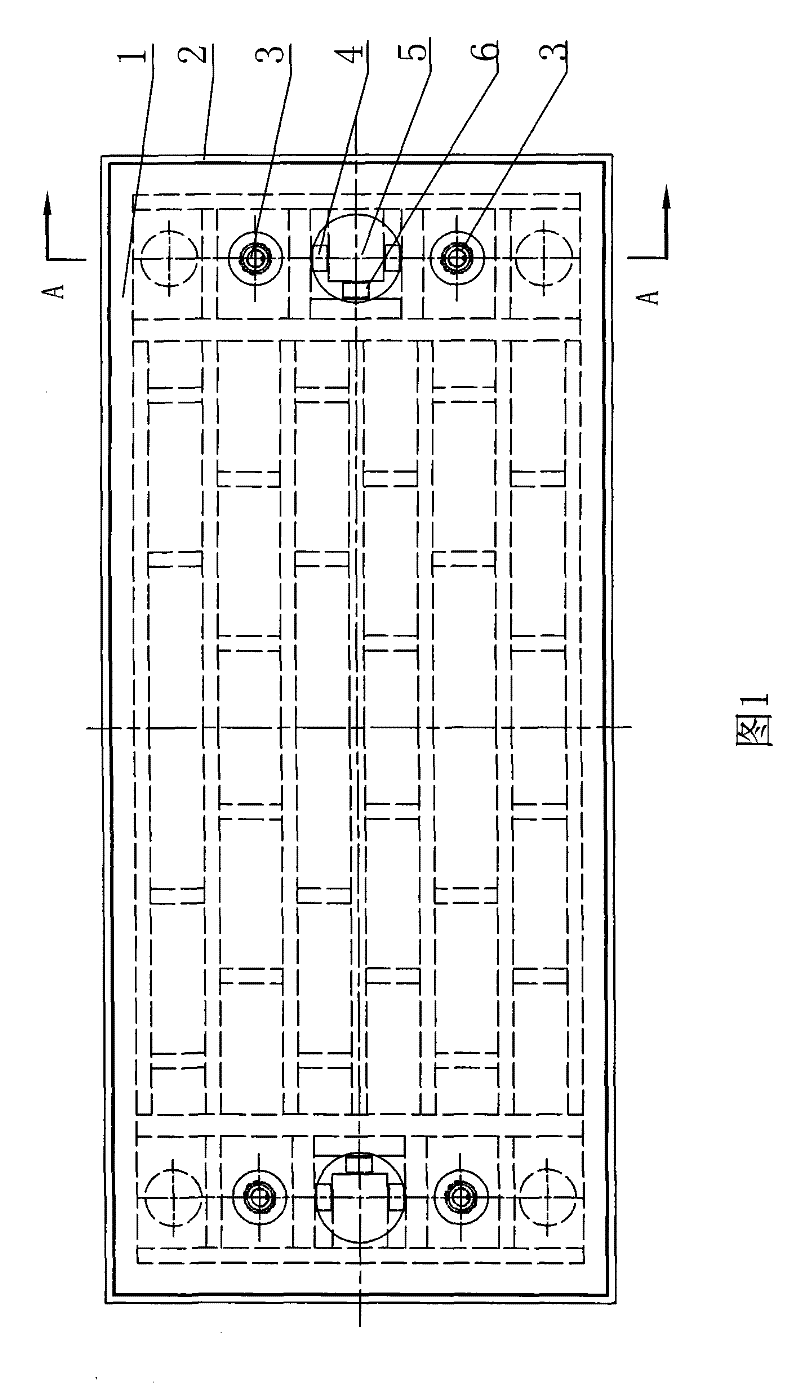

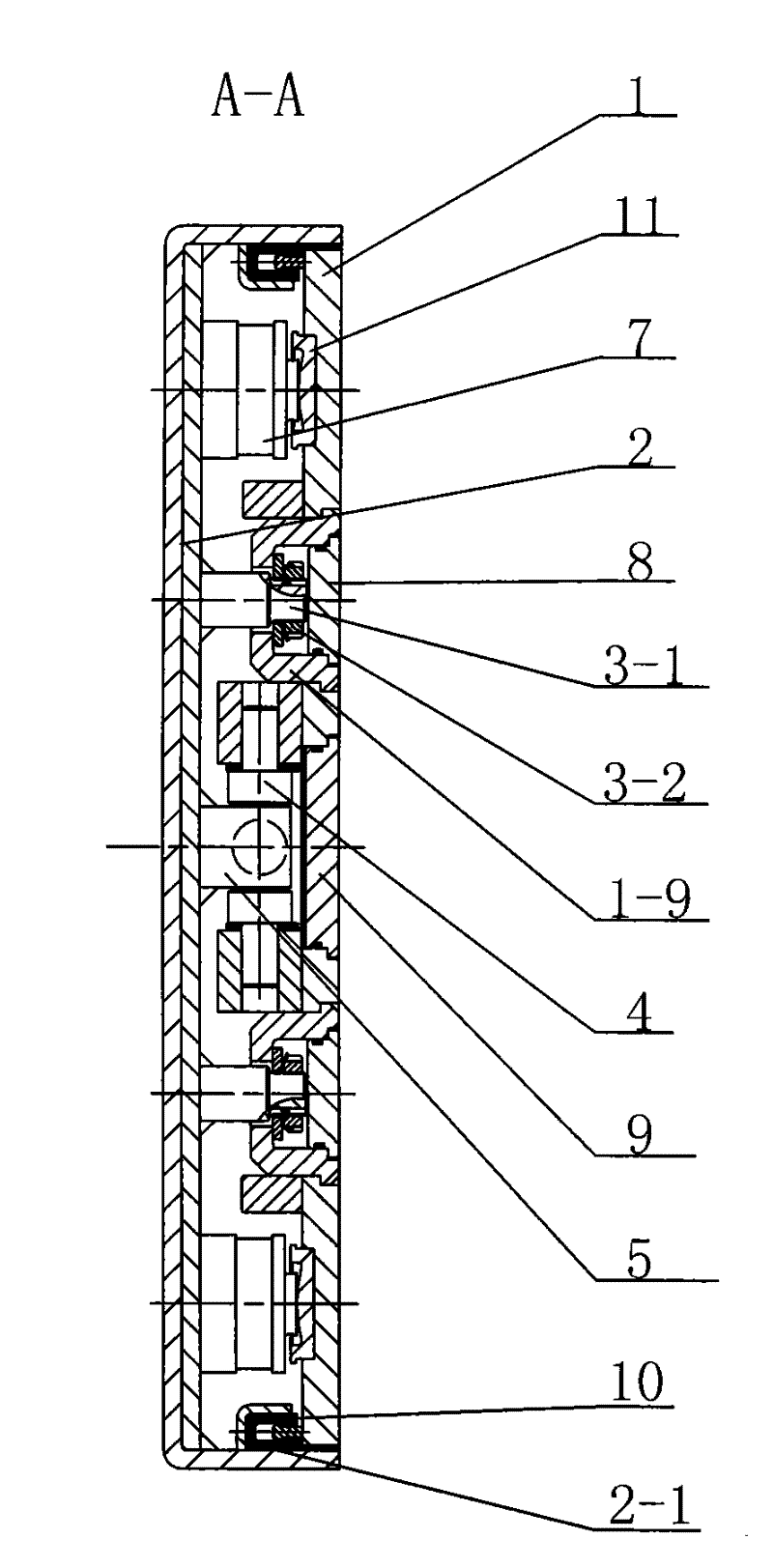

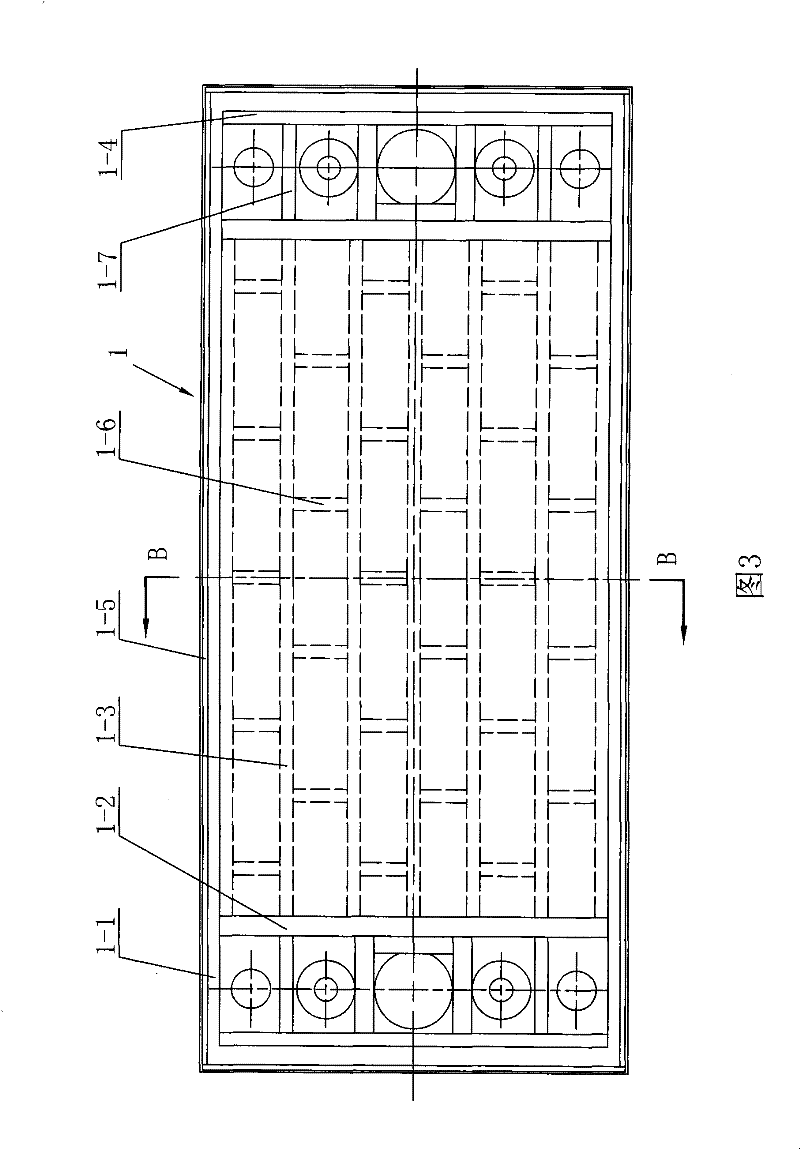

[0020] The road vehicle integrated axle load scale of the present invention comprises a weighing platform 1, a load cell 7 and a weighing instrument. As shown in Figures 1 to 4, the weighing platform 1 of the present invention includes a weighing platform panel 1-1, a mesh rib plate fixed on the bottom of the weighing platform panel 1-1 and two longitudinal end plates 1-4, so that the weighing platform 1 has The structural design of the thin weighing platform is realized due to good mechanical properties, and the height of the weighing platform 1 is between 50-110 mm. See Fig. 1, shown in 2, at least two load cells 7 of the present invention are installed on the box-shaped weighing base 2, and this load cell 7 can adopt column type sensor, button ring type sensor, wheel-spoke type sensor or disc type For low-height load cells such as sensors, 2-8 load cells 7 can be respectively arranged on the side or corner seats on the box-shaped scale base 2, and the output signal lines of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com