Tunnel waterproof structure and method

A technology for waterproof structures and tunnels, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as flash welding, unable to arch wall coils, water leakage, etc., achieve convenient grouting, improve waterproof effect, and Good pulp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

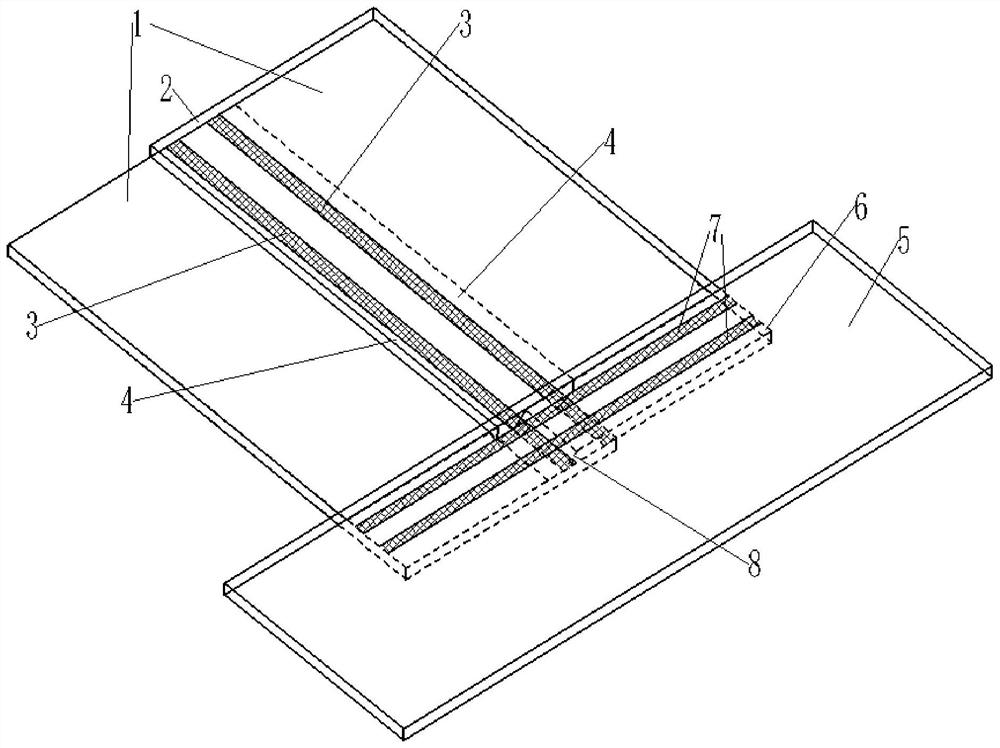

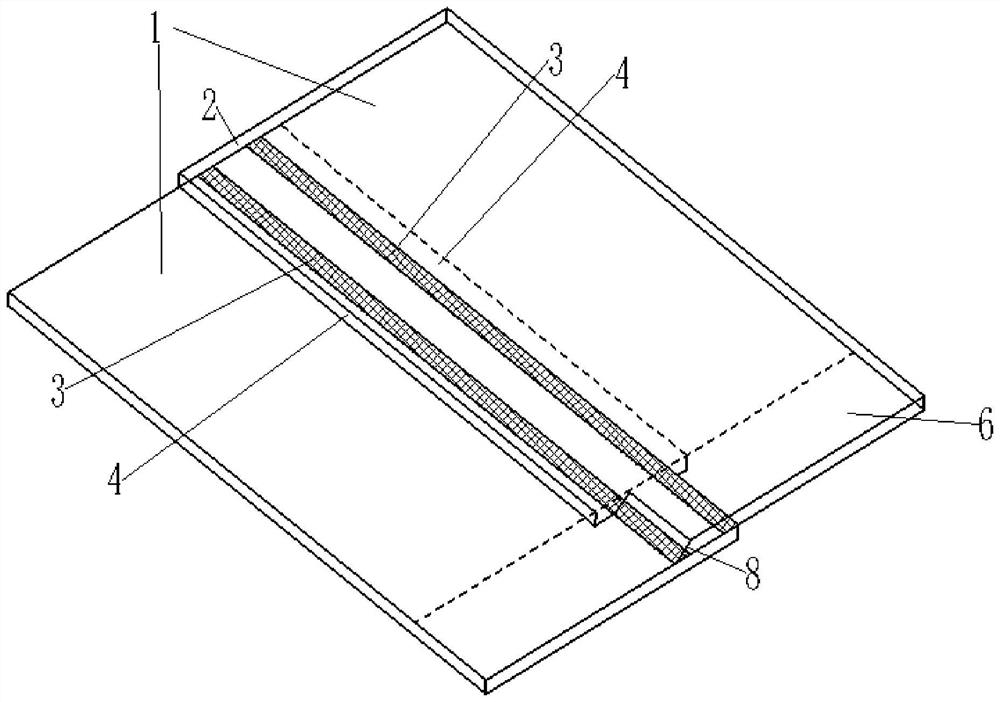

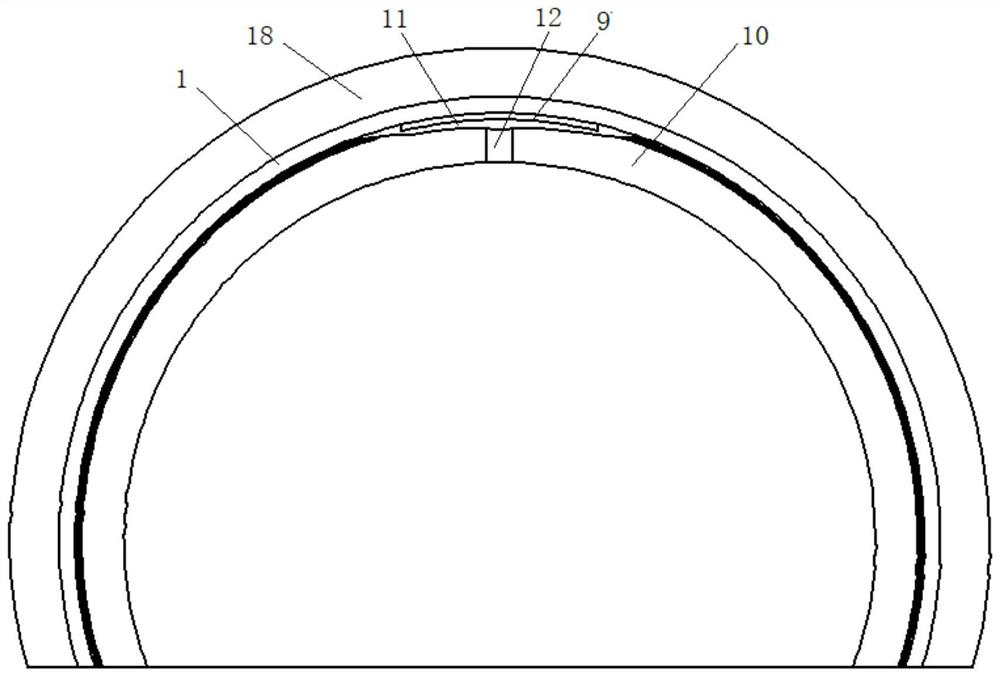

[0105] like Figure 1 to Figure 7 As shown, the present invention provides a tunnel waterproof structure, the waterproof structure includes:

[0106] The first waterproof coiled material 1 is laid on the tunnel arch wall, and two adjacent first waterproof coiled materials 1 are overlapped by their first overlapping edges 2, and the two overlapping first overlapping edges 2 are overlapped with each other. Connected by the first bar-shaped welding portion 3, the first waterproof membrane 1 forms a flash portion 4 on the outer side of the first bar-shaped welding portion 3;

[0107] The second waterproof coiled material 5 is laid on the inverted arch of the tunnel and overlapped with the second lap edge 6 of the first waterproof coiled material 1, and the second waterproof coiled material 5 and the second lapped edge 6 pass through the second The second strip welding part 7 is perpendicular to the first strip welding part 3;

[0108] The flash portion 4 between the second overl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com