Efficient filtering type shale gas exploitation device

A technology for shale gas extraction and high-efficiency filtration, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc. It can solve the problems of internal structure damage and inability to intercept stones, and achieve the effect of improving the screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

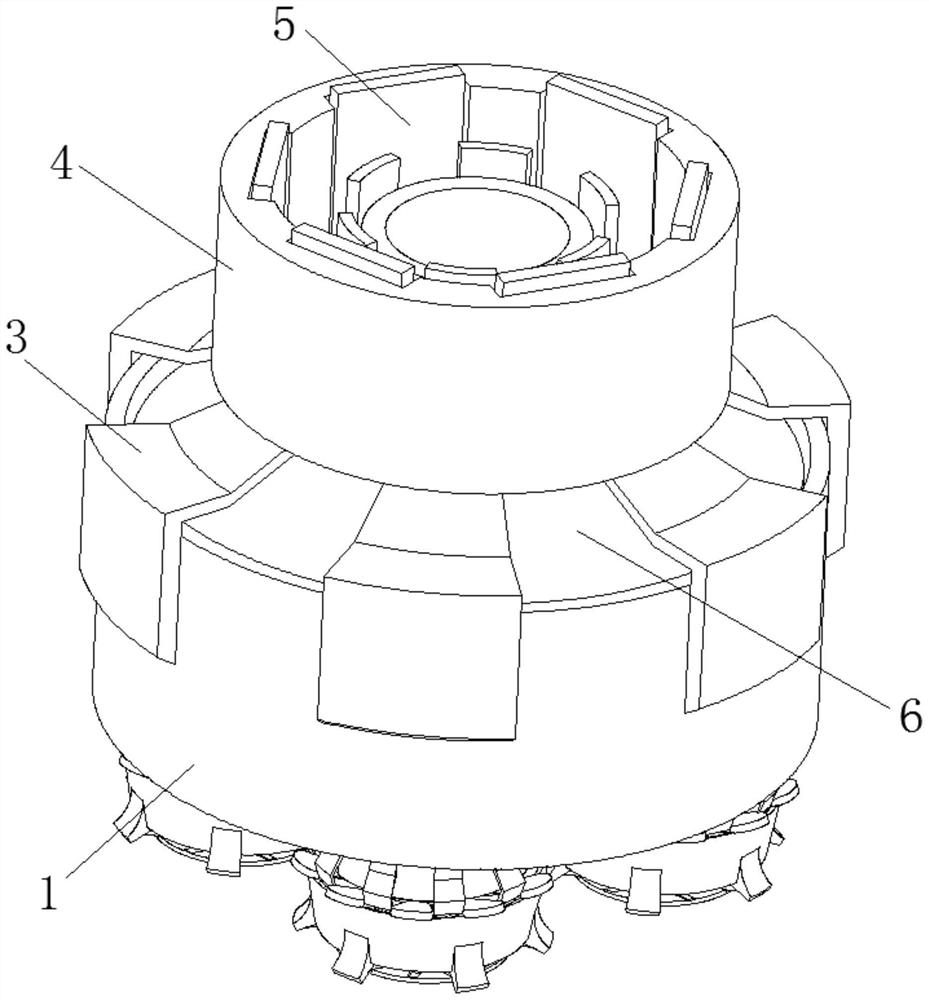

[0028] like Figure 1-2 As shown, the present invention provides a technical solution: a high-efficiency filtration type shale gas exploitation device, comprising a exploitation shell 1, the top of the exploitation shell 1 is fixedly connected with an outer anti-extrusion plate 3, the outer anti-extrusion plate 3 is The upper surface of the plate 3 is fixedly connected with a collection tube shell 4, the inner wall of the collection tube shell 4 is fixedly connected with an inner expansion plate 5, and the inside of the mining shell 1 is fixedly connected with a collection device 6, and the collection device 6 includes The upper sealing collecting pipe 61, the outer surface of the upper sealing collecting pipe 61 is sleeved inside the mining shell 1, the bottom of the inner surface of the mining shell 1 is fixedly connected with the mining unit 67, and the mining unit 67 penetrates the inside of the mining shell 1 The bottom of the surface extends to the bottom side, the top o...

Embodiment 2

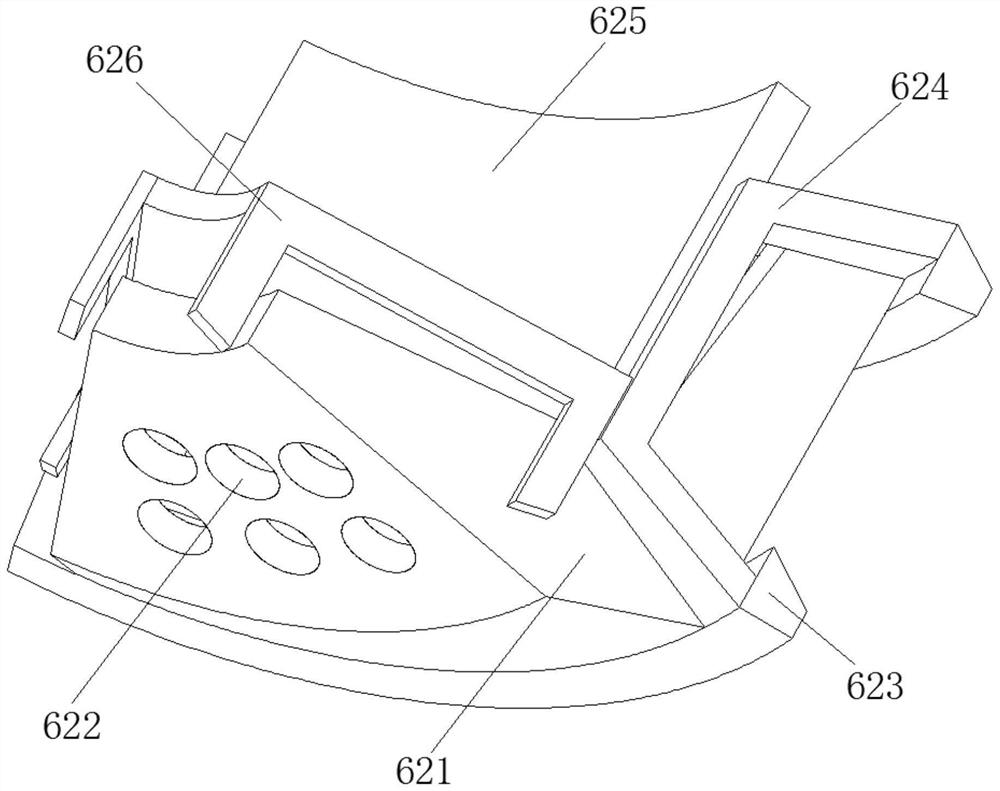

[0033] like image 3 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the plugging device 62 includes a pressure flap 621, and the back of the pressure flap 621 is fixedly connected to the end of the inner sleeve rod 64 , the upper and lower sides of the back of the pressure flap 621 are fixedly connected with a side glue cover 623 , and both sides of the side glue cover 623 are fixedly connected with a stress pressure rod 624 .

[0034] An inner air guide plate 625 is fixedly connected between the opposite surfaces of the stress pressure rod 624, and a card insertion rod 626 is fixedly connected to the side of the bottom of the inner air guide plate 625, and the bottom ends of the card insertion rod 626 are respectively It is sleeved on the outer surface of the bottom of the pressure folded plate 621 , and the bottom surface of the pressure folded plate 621 is provided with screening through holes 622 . When the flow rate o...

Embodiment 3

[0039] like Figure 4-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the mining unit 67 includes an inner impurity preventing device 671, and the outer surface of the bottom of the inner impurity preventing device 671 is fixedly connected with an external The board member 676, the inner board 672 is fixedly connected to the space between the external board member 676.

[0040] A screening sleeve 673 is fixedly connected to the bottom of the inner plate 672 , a preset pressing block 675 is fixedly connected to the bottom of the screening sleeve 673 , and a circular hole plate 674 is fixedly connected to the bottom of the predetermined pressing block 675 .

[0041] The inner anti-miscellaneous device 671 includes an inner connecting casing 6711, the top of the inner connecting casing 6711 is fixedly connected between the opposite surfaces of the external plate 676, and the inner connecting casing 6711 is sleeved w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com