Anti-oxidation polymerization inhibition UVLED coating

An anti-oxidative polymerization and oxygen-inhibited technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem that the surface of the paint film is easily affected by the inhibition of oxygen polymerization, and the surface hardness, scratch resistance and wear resistance of the paint film are not good. It can achieve the effect of eliminating oxygen polymerization inhibition, improving overall performance and reducing polymerization inhibition.

Active Publication Date: 2022-08-09

GUANGDONG HEYGEY LIGHT CURING MATERIALS

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005]

Aiming at the problems existing in the prior art: using UVLED lamps as the light source to light-cure the coating system, the surface of the paint film is easily affected by oxygen inhibition, resulting in poor surface hardness, scratch resistance and wear resistance of the coating film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

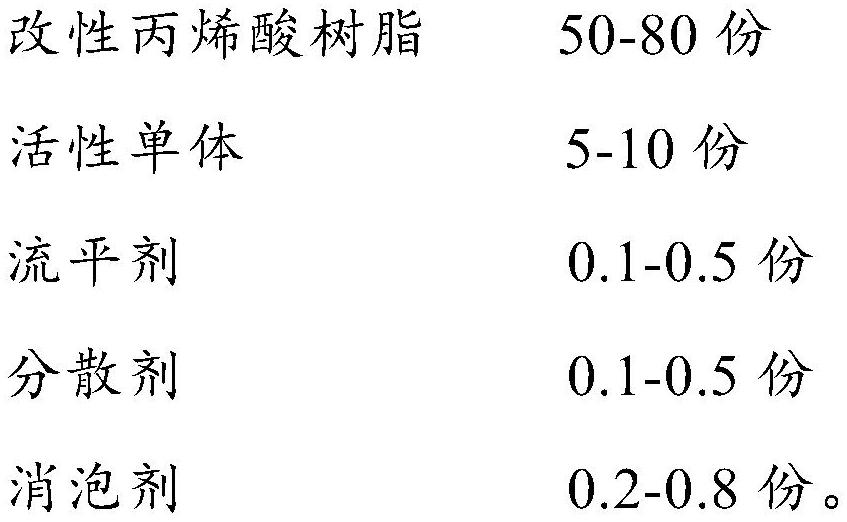

[0040] An anti-oxidative polymerization-inhibiting UVLED coating, in parts by weight, has the following components:

[0041]

Embodiment 2

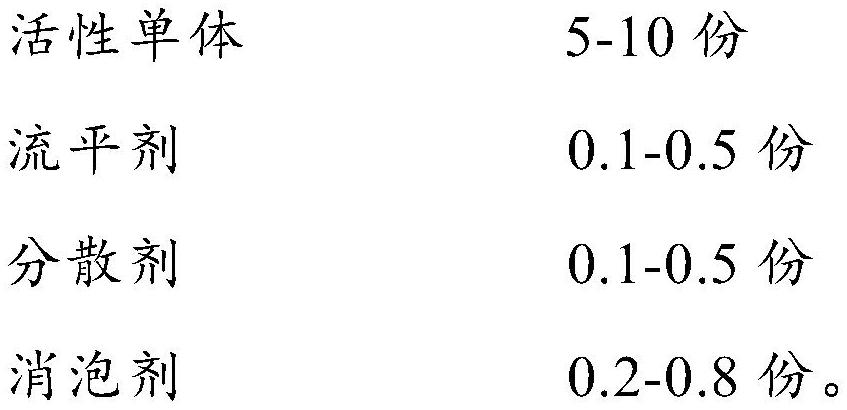

[0043]An anti-oxidative polymerization-inhibited UVLED coating, in parts by weight, has the following components:

[0044]

Embodiment 3

[0046] An anti-oxidative polymerization-inhibited UVLED coating, in parts by weight, has the following components:

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of photocureable coatings, in particular to an anti-oxidation polymerization inhibition UVLED coating. A UVLED lamp is used as a light source to carry out light curing on a paint system, and the surface of a paint film is easily influenced by oxygen inhibition, so that the surface hardness, the scratch resistance and the wear resistance of the paint film are poor. In order to solve the problems, the invention provides the anti-oxygen-inhibition UVLED coating, the self-made modified acrylic resin structure in the formula contains a large number of ethyoxyl groups, on one hand, alpha-H in the ethyoxyl groups is easily substituted by oxygen, and the reaction can consume part of oxygen in the system; on the other hand, the alpha-H can terminate peroxide free radicals formed by free radicals and oxygen to form new active free radicals, so that the polymerization inhibition effect of oxygen on the photocuring process is reduced.

Description

technical field [0001] The invention relates to the technical field of photocurable coatings, in particular to an anti-oxidative and polymerization-inhibited UVLED coating. Background technique [0002] In the light-curing coating system, the mercury lamp is the most commonly used. Although the mercury lamp has high energy, wide ultraviolet wavelength range and high light curing efficiency, the use of the mercury lamp will generate ozone molecules, which are harmful to human health and the ozone layer in the atmosphere. are very dangerous. [0003] UVLED lamps are energy-saving and environmentally friendly, with low heat release, long life, and no ozone generation. However, its conventional wavelength bands are 405, 395, 385, 365 nm, etc., all of which are medium and long wavelength bands. The matching degree between the wavelength of the light source and the absorption peak of the photoinitiator is not high, resulting in less free radicals, and the surface of the paint fil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/14C09D7/65

CPCC09D175/14C09D7/65C08L83/08

Inventor 赖俊伟彭建华吴勇

Owner GUANGDONG HEYGEY LIGHT CURING MATERIALS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com