Special carrier for pneumatic logistics conveying inspection test tubes

A technology for transferring inspection and test tubes, applied in the field of logistics transfer bottles, can solve the problems of contamination of the inner space of the transfer bottle, no protection of the contents, loss of test specimens, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

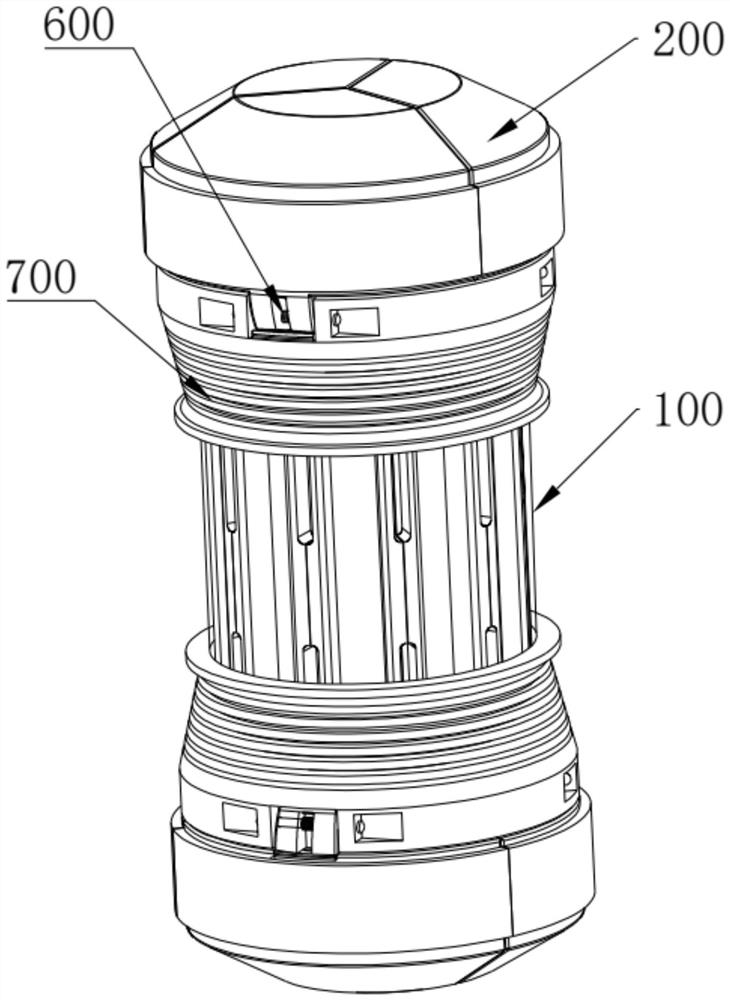

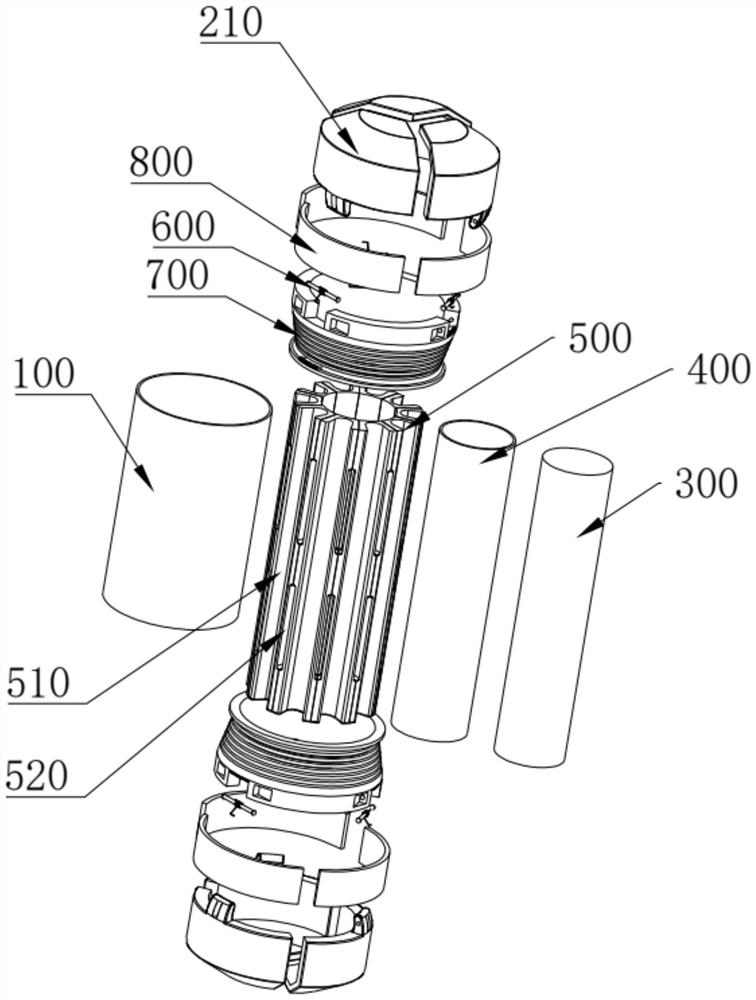

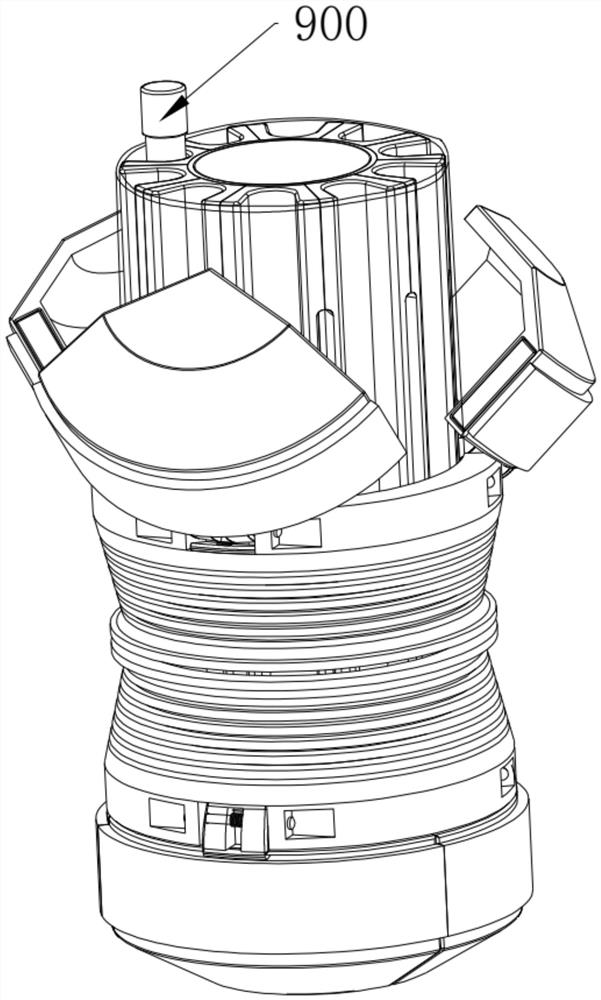

[0039] A special vehicle for pneumatic logistics conveying test tubes, such as Figure 1-4 As shown, it includes a bottle body 100 with a cavity inside and a bottle cap 200 that is closed at the bottle mouth of the bottle body 100, and is vertically arranged in the cavity of the bottle body 100 for fixing and buffering the test tube 900. Buffer components.

[0040] The test tube 900 is fixed and buffered by the vertically arranged fixed buffer assembly. When the blood, urine and stool reagent is delivered, the tube walls of the test tube 900 will not collide with each other during the transmission process, which effectively ensures the safety of reagent delivery and the stability of the substances in the reagent. . The hematuria and stool reagent is only shaken in the vertical direction in the test tube 900, which can ensure that the substances in the reagent will not be remixed after sedimentation and stratification, thereby avoiding the problem of the deterioration of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com