Multi-laser coupled three-dimensional complex curved surface multi-scale structure manufacturing equipment and method

A technology for complex curved surfaces and manufacturing equipment, applied in laser welding equipment, manufacturing tools, welding equipment, etc. To meet the needs of mass production and other issues, to achieve the effect of simple and easy technical means, highlighting substantial progress, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

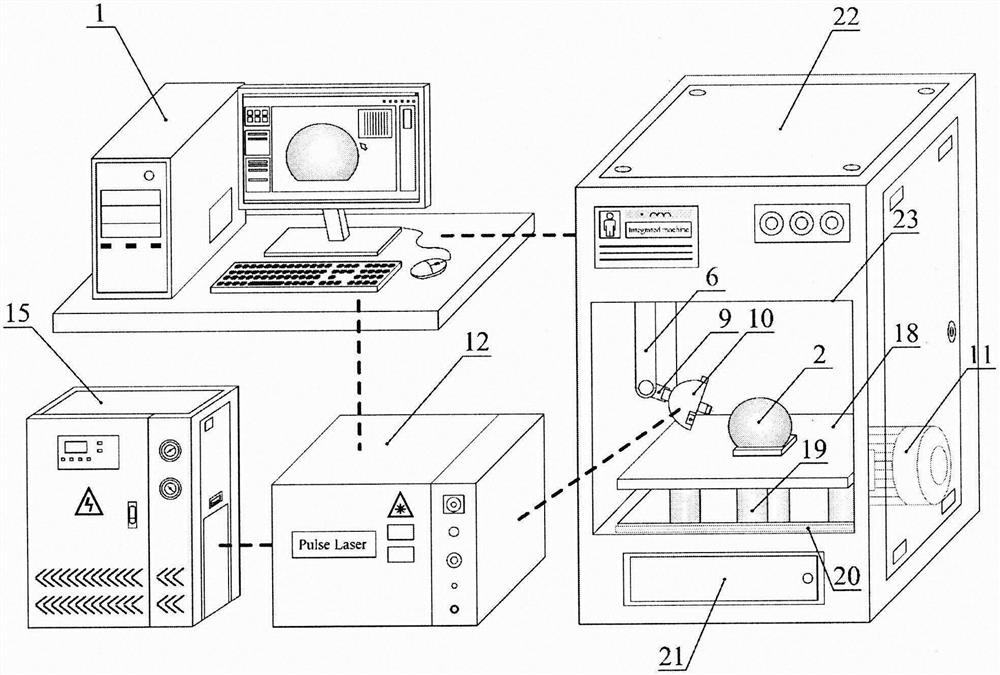

[0035] like figure 1 shown. The invention discloses a multi-laser coupling three-dimensional complex curved multi-scale structure manufacturing equipment, comprising a computer control system, a displacement system, a three-dimensional scanning system, a pattern design system, a processing planning system, a laser etching system and a collection system;

[0036] The computer control system is connected to the displacement system, the three-dimensional scanning system, the pattern design system, the processing planning system, the laser etching system and the collection system;

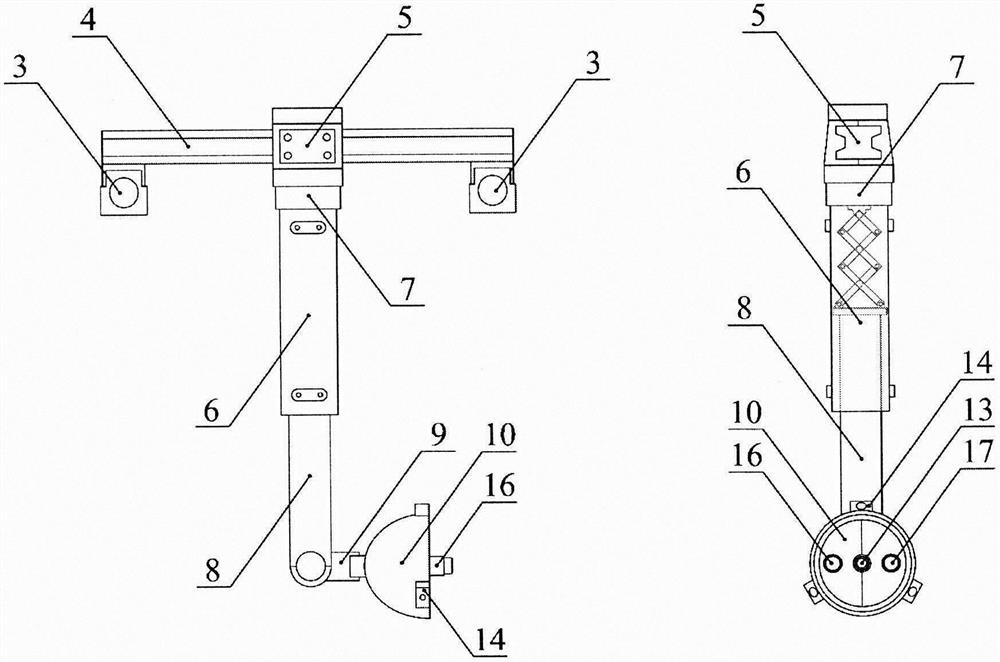

[0037] The displacement system is used to drive the dynamic displacement of the laser head in the three-dimensional space, so as to cooperate with the laser head to perform three-dimensional scanning and laser etching processing on the processed object 2, including: dual rails 3, guide rails 4, sliders 5, and robotic arms 6 , Rotating mechanism 9 , laser head converter 10 , motor 11 . Among them, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com