Solar photo-thermal coupling phase conversion carbon dioxide reduction catalytic reaction system and method

A light-thermal coupling and carbon dioxide technology, applied in chemical instruments and methods, separation methods, energy input, etc., can solve problems such as discontinuity of solar energy, unstable influence of solar climate and meteorological conditions, and constant difficulty of sunlight temperature, etc. To achieve the effects of effective illumination and stability promotion, effective illumination and good stability, airtightness and light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

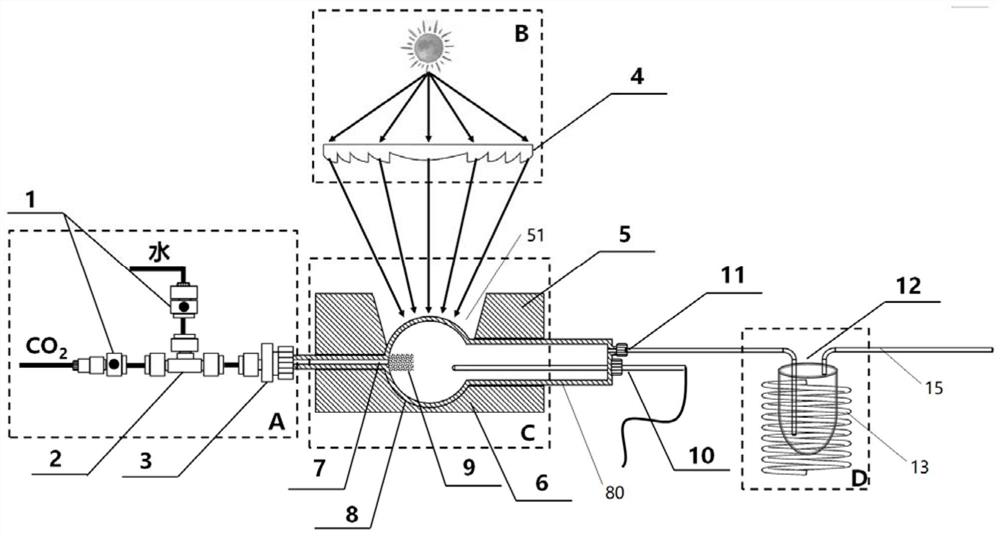

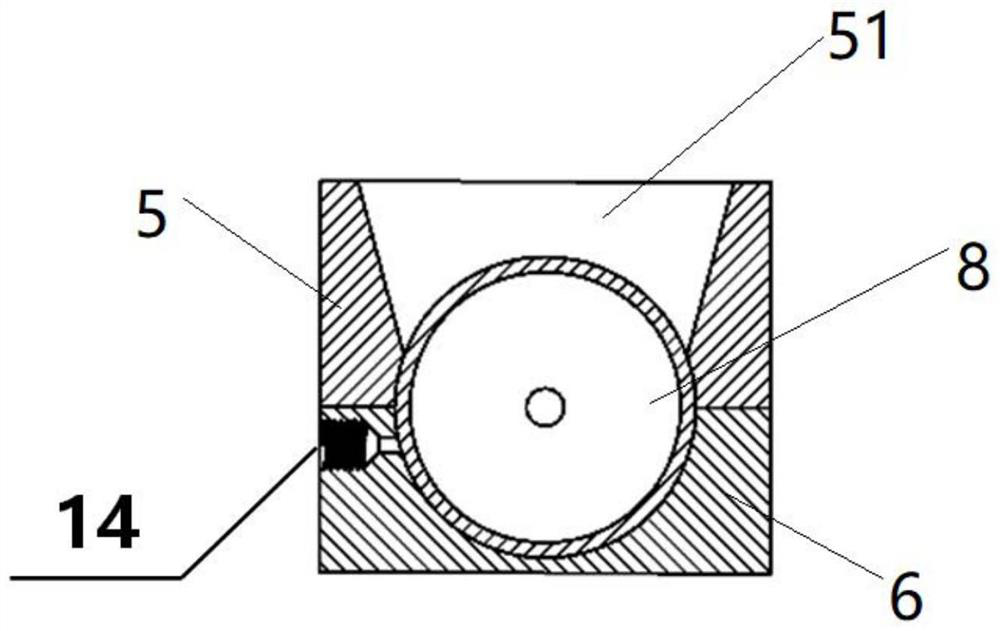

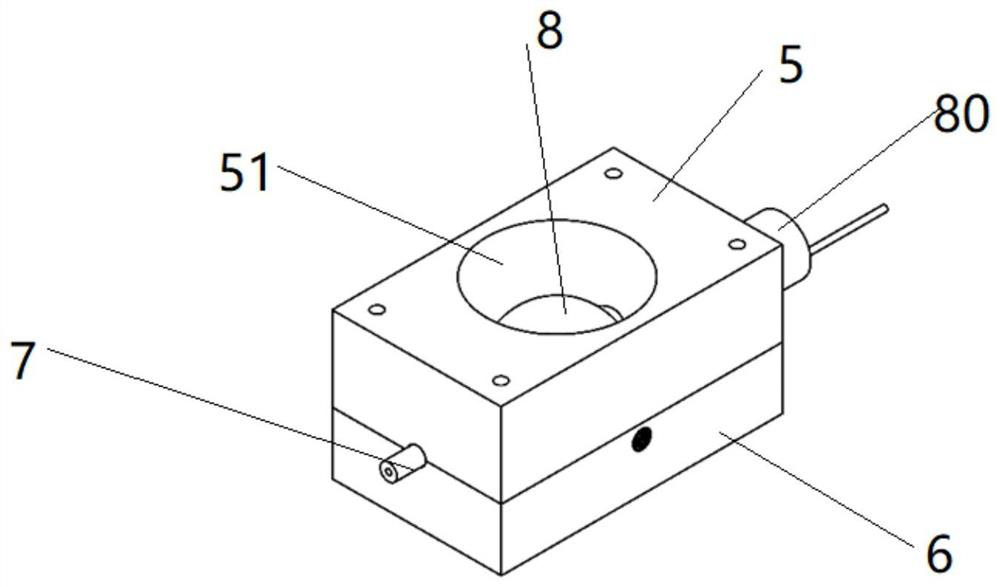

[0039] see Figure 1 to Figure 3 As shown, a solar-photothermal coupled phase conversion carbon dioxide reduction catalytic reaction system includes a feeding device A, a Fresnel lens concentrating device B, a high temperature phase inversion reaction device C and a product cooling analysis device D. Wherein the feeding device A, the high temperature phase inversion reaction device C and the product cooling analysis device D are connected through a conduit.

[0040] The feeding device A mainly includes: a flow control system 1, a T-type gas-liquid mixing valve 2 and a gas-liquid mixture dispersion system 3; the two input ends of the T-type gas-liquid mixing valve 2 are respectively connected to a water input pipe and a carbon dioxide input pipe; the water input pipe A flow control system 1 is provided on each of the carbon dioxide and carbon dioxide input pipes. The output end of the T-type gas-liquid mixing valve 2 is connected to the input end of the high temperature phase ...

Embodiment 2

[0050] The invention provides a solar photothermal coupled phase conversion carbon dioxide reduction catalytic reaction, comprising the following steps:

[0051] water and CO 2 The gas enters the T-type gas-liquid mixing valve 2 through the flow control system 1 of each branch, thereby determining the water / CO of the reaction system. 2 Proportion. while water and CO 2 The gas enters the gas-liquid mixture dispersion system 3 in the form of a gas-liquid mixture after passing through the T-type gas-liquid mixing valve 2, and enters the phase inversion preheating pipe 7 through atomization and dispersion. The gas-liquid mixture passing through the phase inversion preheating tube 7 is formed to uniformly disperse water vapor and CO 2 The gas form is sprayed into the high temperature reaction zone 8 through the porous steam spray head 9 to participate in the reaction. The product is introduced into the product cooling analysis device D through the gas outlet 11, wherein the liq...

Embodiment 3

[0054] In this example, a solar photothermal coupled phase conversion carbon dioxide reduction catalytic reaction system of the present invention is used for Co 3 O 4 Loaded CuO x Thin-film Photothermal Catalysts Solar Photothermal Coupled Catalysis of CO 2 Reduction reaction: 1x1cm size Co 3 O 4 / CuO x The thin film photothermal catalyst is placed in the spherical reaction zone 81 . CO control via gas flow meter 2 The flow rate is 10sccm, the flow rate of the water controlled by the syringe pump is 20mL / min, the inner diameter of the phase conversion preheating pipe 7 is 1mm, and the length of the phase conversion preheating pipe 7 placed in the heating zone is 6mm; The inner wall ball diameter is 15mm, the porous steam jet head 9 is sintered integrally with the phase conversion preheating tube 7, the diameter is the same as the phase conversion preheating tube, the length is 1.2 times the diameter, and the pore size is 50nm; the built-in thermocouple 10 is T-shaped , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com