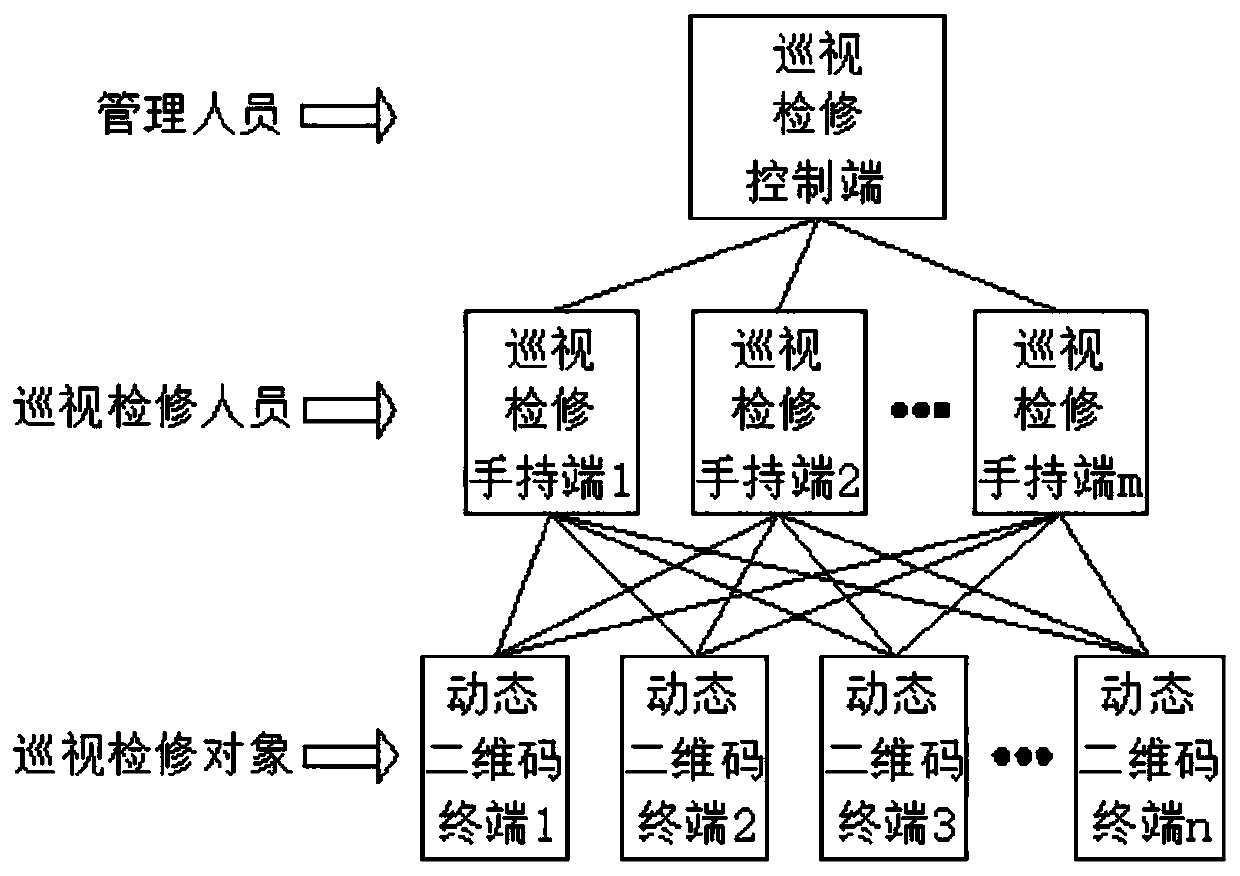

Intelligent inspection and maintenance method and system based on satellite dynamic two-dimensional code

A dynamic two-dimensional code, inspection and maintenance technology, applied in the field of automation, can solve problems such as the signal being easily affected by electromagnetic interference, the inability to detect and deal with equipment safety hazards in time, the inability to complete the statistical analysis and mining application of inspection and maintenance data, etc., to avoid problems such as The effect of manual tedious input work and avoiding the phenomenon of inspection and maintenance cheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The intelligent inspection and maintenance method based on the satellite dynamic two-dimensional code proposed by the present invention comprises the following steps:

[0032] (1) Generate a task book to be inspected and repaired, and arrange multiple objects to be inspected and repaired in order in the task book, and the task book includes the serial number n of each object to be inspected and repaired 0 , longitude and latitude position coordinates [a 0 ,b 0 ] and inspection and maintenance list;

[0033] (2) According to the longitude and latitude position coordinates of the objects to be inspected and overhauled in the task book [a 0 ,b 0 ] to find the target inspection and maintenance object;

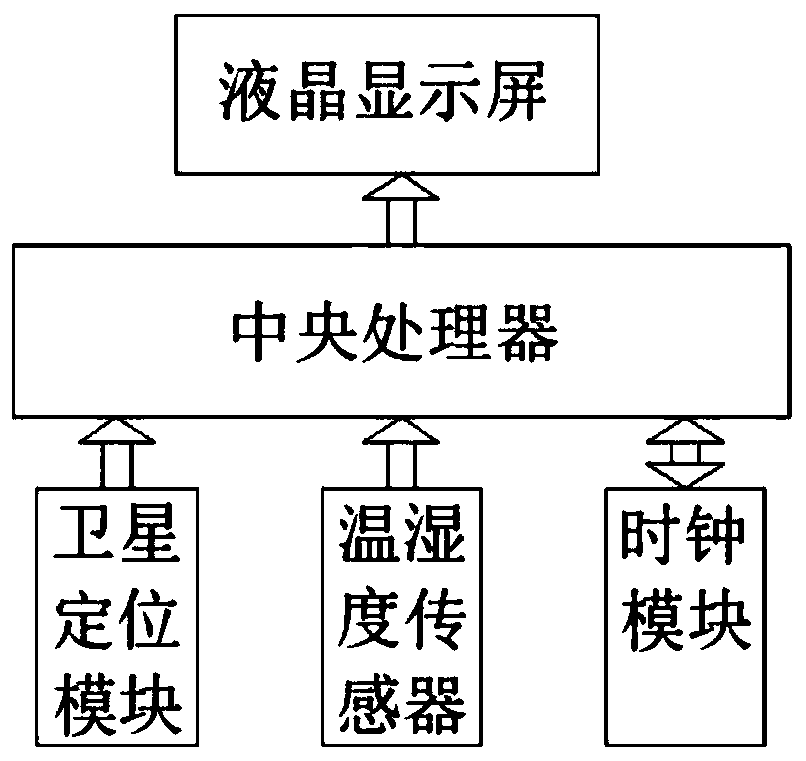

[0034] (3) Scan the dynamic two-dimensional code of the target inspection and maintenance object, and record the scanning time t 0 , to obtain the information [n, f(a), g(b), h(t), T, H] of the dynamic two-dimensional code when scanning, where n is the serial number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com