Bleaching and dyeing wastewater collecting and separating device

A separation device and wastewater collection technology, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of unable to automatically lint, lint with too much water, and unable to control the flow of wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

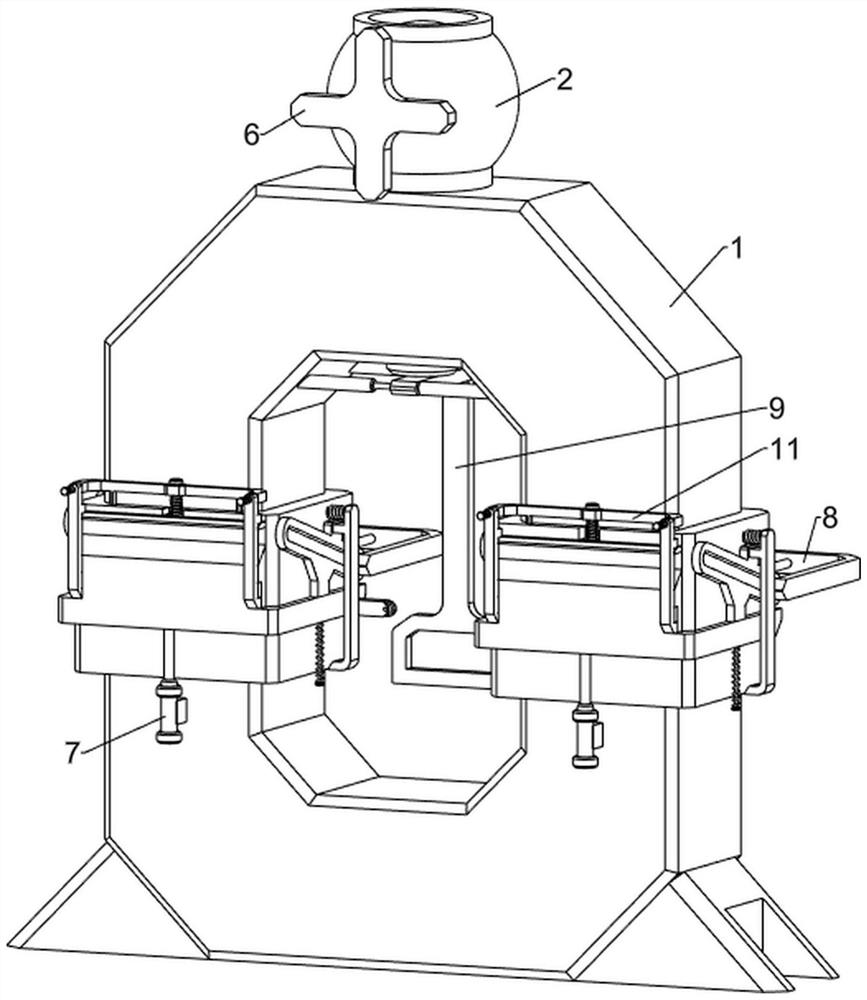

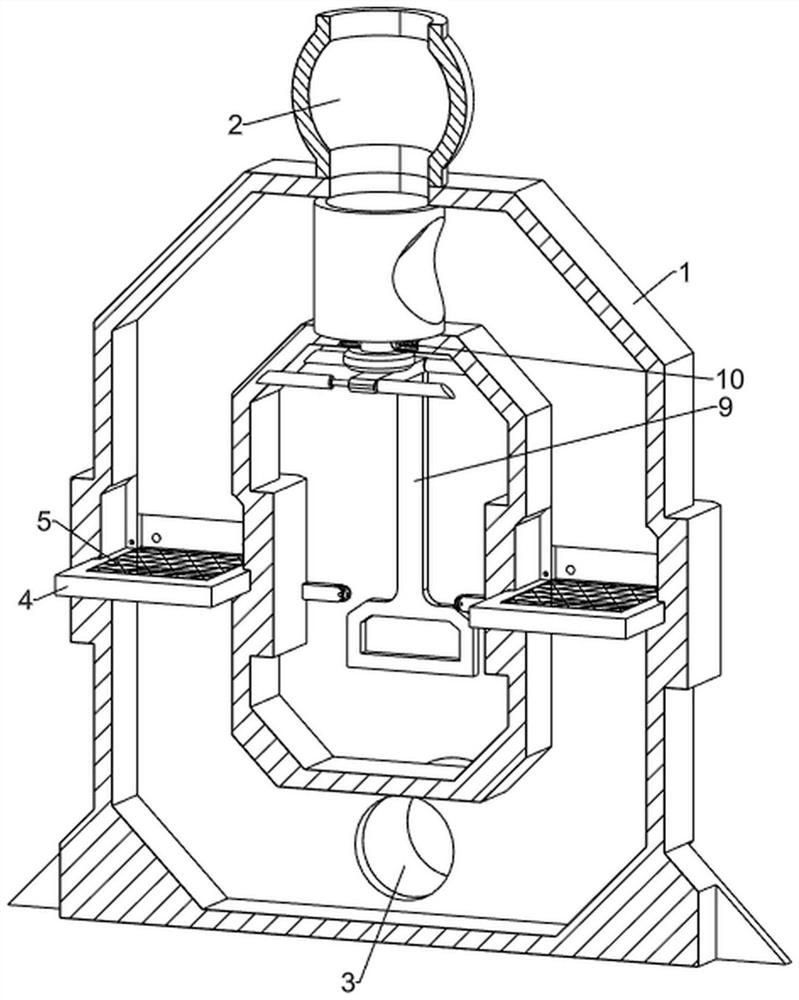

[0037] A bleaching and dyeing wastewater collection and separation device, such as figure 1 and figure 2 As shown, it includes a casing 1, a water inlet pipe 2, a drainage pipe 3, a support plate 4, a filter screen 5, a switch assembly 6, a closing assembly 7 and a scraping assembly 8. The upper side of the casing 1 is connected with a water inlet pipe 2, and the casing The lower side of the rear part of the body 1 is connected with a drain pipe 3, the inner side of the middle part of the housing 1 is symmetrically provided with a support plate 4, and the support plates 4 are connected with a filter screen 5, a switch assembly 6 is arranged on the drain pipe 3, A closing component 7 is symmetrically arranged, and a scraping component 8 is provided between the middle of the housing 1 and the closing component 7 .

[0038] like image 3 As shown, the switch assembly 6 includes a ball valve 61, a connecting rod 62 and a handle 63, a ball valve 61 is rotatably provided in the w...

Embodiment 2

[0043] On the basis of Example 1, as Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, it also includes a conversion assembly 9. The conversion assembly 9 includes a guide block 91, a turntable 92, a second connecting rod 93, a first guide rod 94, a third connecting rod 95, a fourth connecting rod 96, and a support rod 97. And the roller 98, the upper part of the inner side of the housing 1 is rotatably provided with a guide block 91, the lower side of the middle part of the guide block 91 is connected with a turntable 92, the lower side of the turntable 92 is connected with a second connecting rod 93, and the upper part of the housing 1 is symmetrically connected with A first guide rod 94, a third connecting rod 95 is slidably connected between the first guide rods 94, the third connecting rod 95 is slidably and rotatably connected with the second connecting rod 93, and the lower part of the third connecting rod 95 is connected at the rear side There is a fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com