Slope compensation circuit applied to current mode DC-DC converter

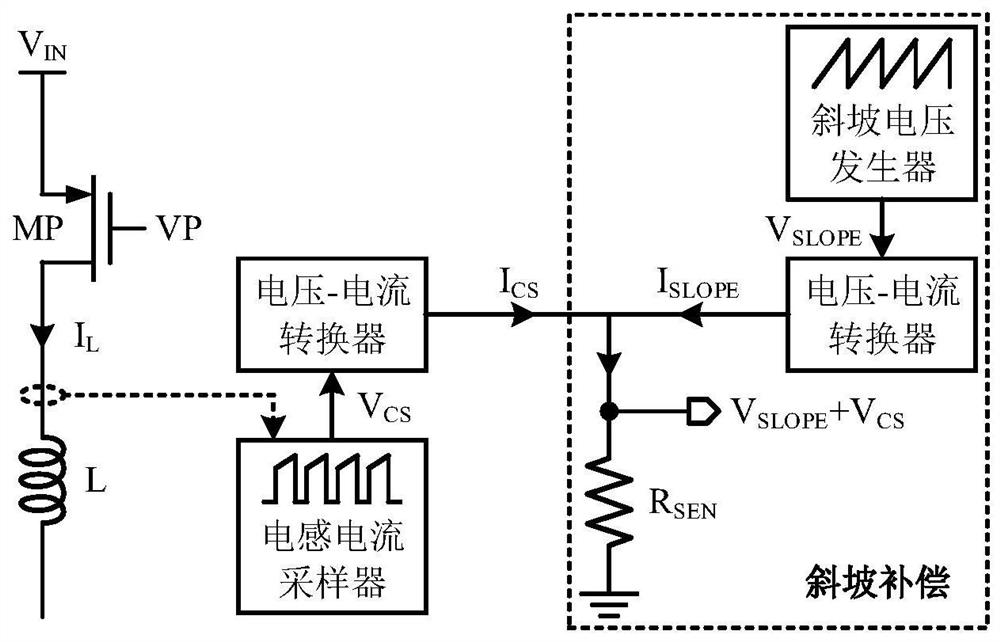

A technology of slope compensation and converter, which is applied in the direction of high-efficiency power electronic conversion, output power conversion device, electrical components, etc., can solve the problem of increasing converter chip area and controlling circuit power consumption, large circuit scale, and voltage-current converter Complicated structure and other issues, to achieve the effect of reducing power consumption, reducing chip area, and reducing circuit scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

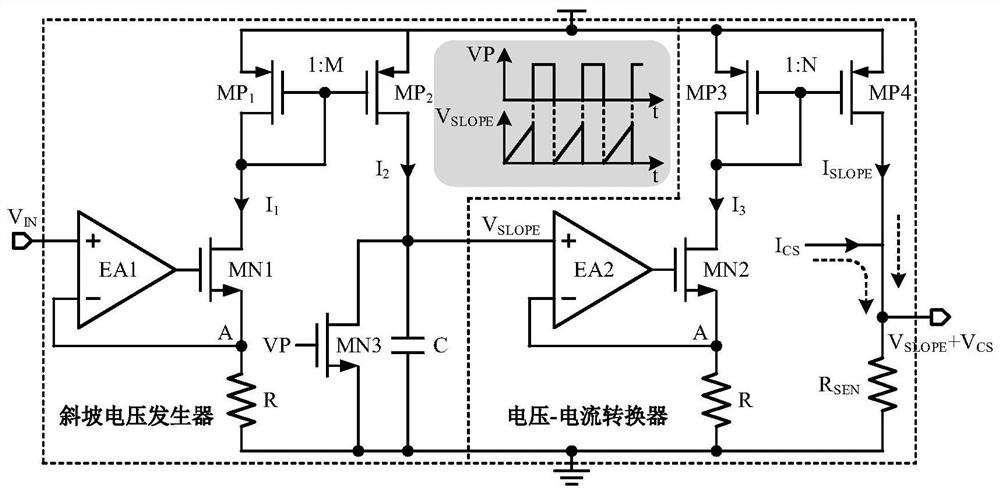

Method used

Image

Examples

Embodiment 1

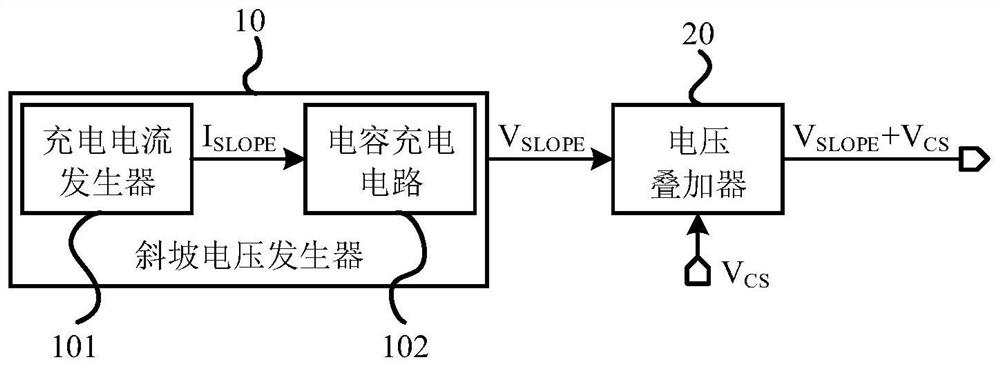

[0040] See image 3 , image 3 It is a structural block diagram of a slope compensation circuit provided by an embodiment of the present invention. As shown in the figure, the slope compensation circuit of this embodiment includes a slope voltage generator 10 and a voltage stacker 20, wherein the slope voltage generator 10 is used for Generate ramp voltage V SLOPE ; the voltage superimposed 20 is used to ramp the voltage V SLOPE with the inductor current sampling voltage V CS superimposed, and output the superimposed signal V SLOPE +V CS , to achieve slope compensation.

[0041] The ramp voltage generator 10 includes a connected charging current generator 101 and a capacitor charging circuit 102; the output terminal of the capacitor charging circuit 102 is connected to the input terminal of the voltage stacker 20; the charging current generator 101 is used to generate the charging current I SLOPE ; Capacitor charging circuit 102 is used for charging current I according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com