Method and system for conducting three-level air preheating through waste heat of garbage power station

A garbage power station, air preheating technology, applied in separation methods, combustion methods, chemical instruments and methods, etc., can solve problems such as incomplete recovery of deaerators, high-grade energy loss of units, and decline in unit efficiency, so as to improve energy Utilization efficiency, realizing cascade utilization, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

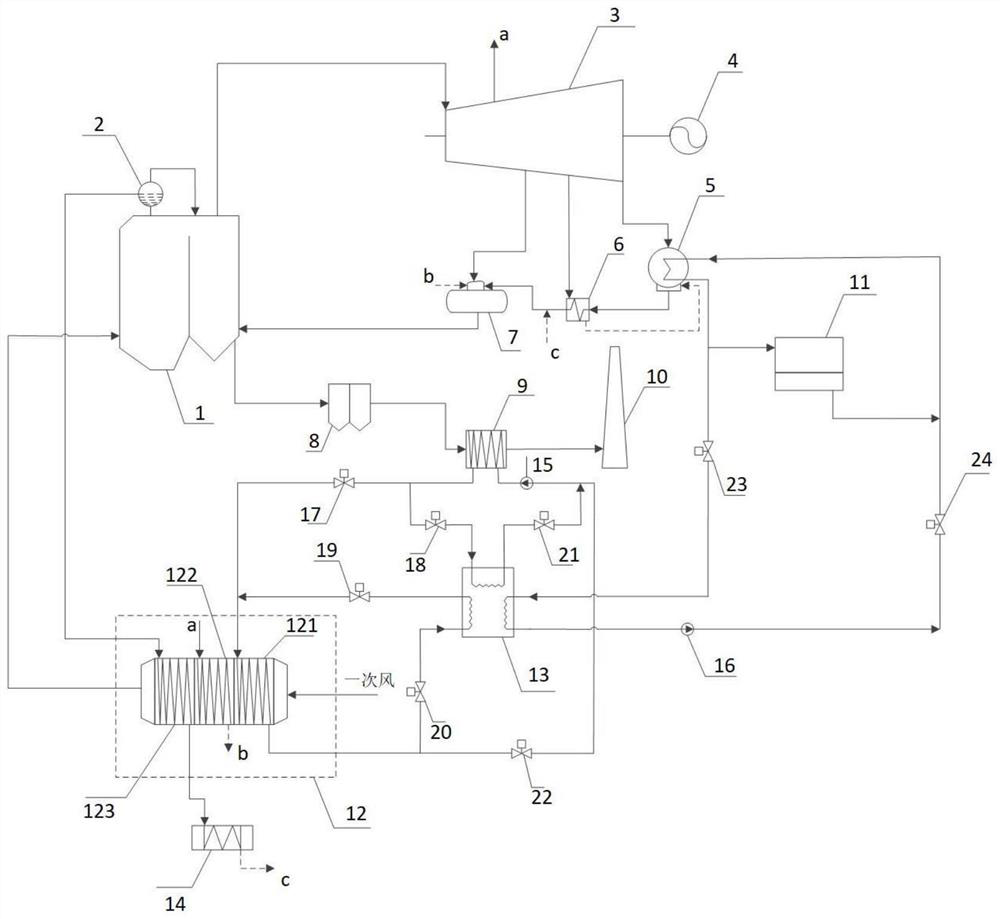

[0025] like figure 1 As shown in the figure, a method for using waste heat from a waste power station to perform three-stage air preheating includes the following steps: the heating heat source of the primary heater 121 switches the first electric valve 17 and the second electric valve 121 according to the temperature of the circulating water at the outlet of the condenser 5 The electric valve 18, the third electric valve 19, the fourth electric valve 20, the fifth electric valve 21, the sixth electric valve 22, the seventh electric valve 23 and the eighth electric valve 24, while adjusting the working mode of the absorption heat pump 13, Select the high temperature circulating water from the outlet of the flue gas heat exchanger 9 or the high temperature heat medium water from the outlet of the hot water side of the absorption heat pump 13 .

[0026] When the temperature of the circulating water at the outlet of the condenser 5 is greater than or equal to the preset temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com