Structure of station side wall formed by combination of omega-shaped inserting plates and convex pilasters and construction method

A technology of inserts and pilasters, which is applied in basic structure engineering, underwater structures, excavation, etc., can solve the problems of late start of research on subway prefabricated structures, narrow construction work space, low construction efficiency, etc., and achieve improved structural construction. The effect of improving the quality, avoiding the difficulty of supporting the formwork and improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

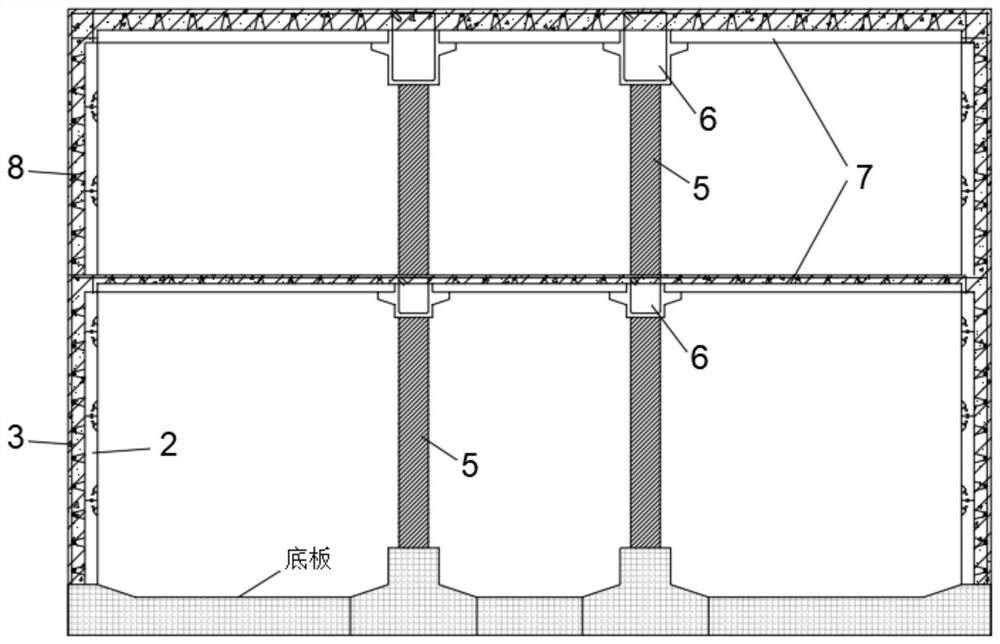

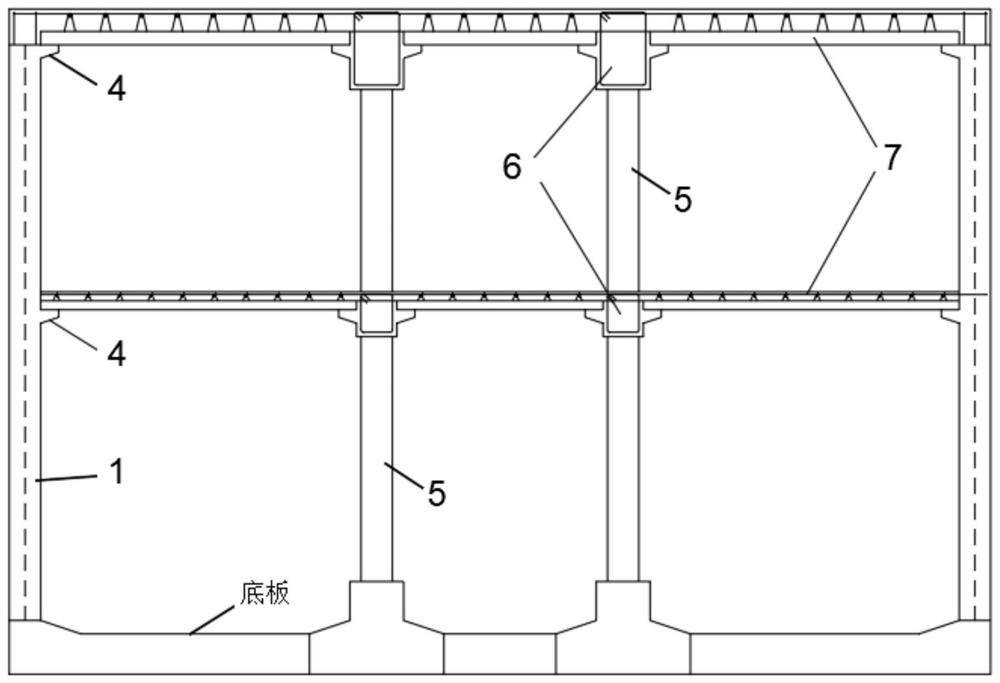

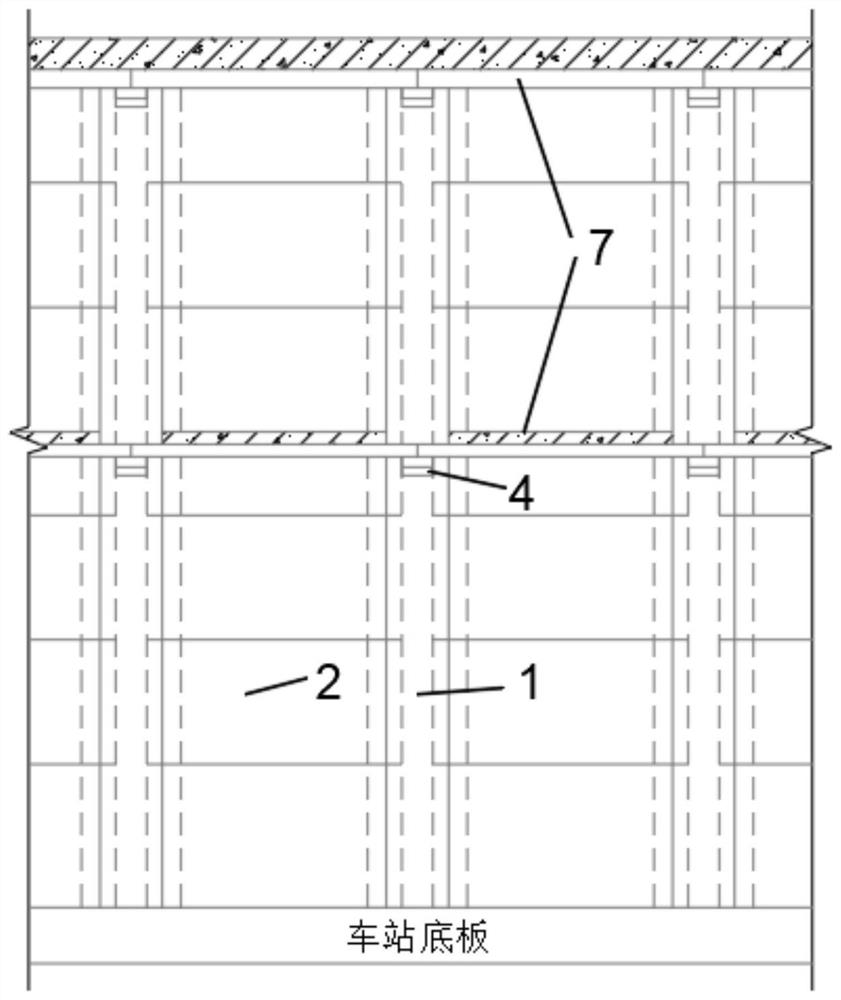

[0053] Step 1: Preparatory work for the required components: After the foundation pit excavation and support are completed, the bottom plate and the bottom longitudinal beam are constructed, and the prefabricated pilasters 1, omega-shaped prefabricated inserts 2 and other components are factory-fabricated and transported in batches to the scene;

[0054] Step 2: Installation of the prefabricated pilaster 1: The prefabricated pilaster 1 and the bottom plate are connected by a grouting sleeve;

[0055] Step 3: On-site assembly of the Ω-shaped prefabricated plug-in board 2 on the side wall of the negative second floor: Assemble the prefabricated plug-in board 2 on the negative second-floor side wall on site, and the two Ω-shaped prefabricated plug-in boards 2 are connected by curved bolts. The plug board 2 is connected with the prefabricated pilaster 1 by bolts;

[0056] Step 4: The pouring of the pouring layer 3 behind the wall;

[0057] Step 5: Installation of the prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com