Antibacterial dumbbell material and antibacterial dumbbell

A technology for dumbbells and membrane materials, applied in dumbbells, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve problems such as accelerated aging, easy breeding of bacteria on the surface of dumbbells, rusting of dumbbell iron materials, etc., to prolong service life and provide comfort The effect of hand feeling and hygienic contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] An antibacterial dumbbell material and an antibacterial dumbbell, the antibacterial dumbbell material comprising a core material for preparing a dumbbell body and a film material for preparing a film layer coated on the surface of the dumbbell body;

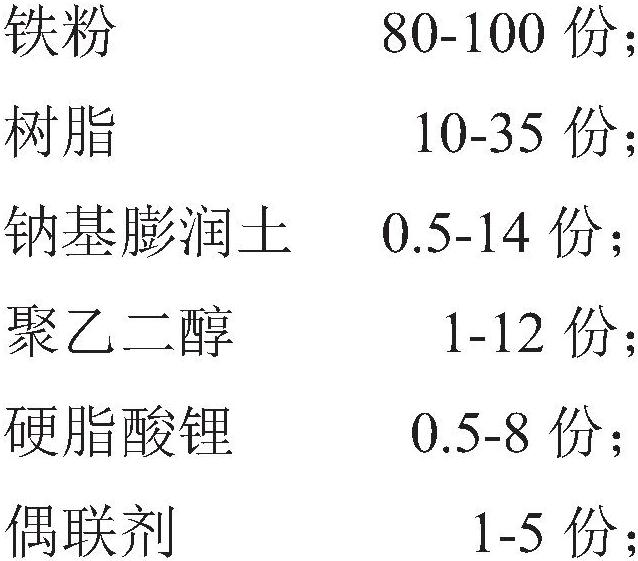

[0074] The core material includes the following components in parts by weight:

[0075]

[0076] Wherein, the resin is a mixture of epoxy resin E20 and polycarbonate, and the mass ratio of epoxy resin and polycarbonate is 7:3.

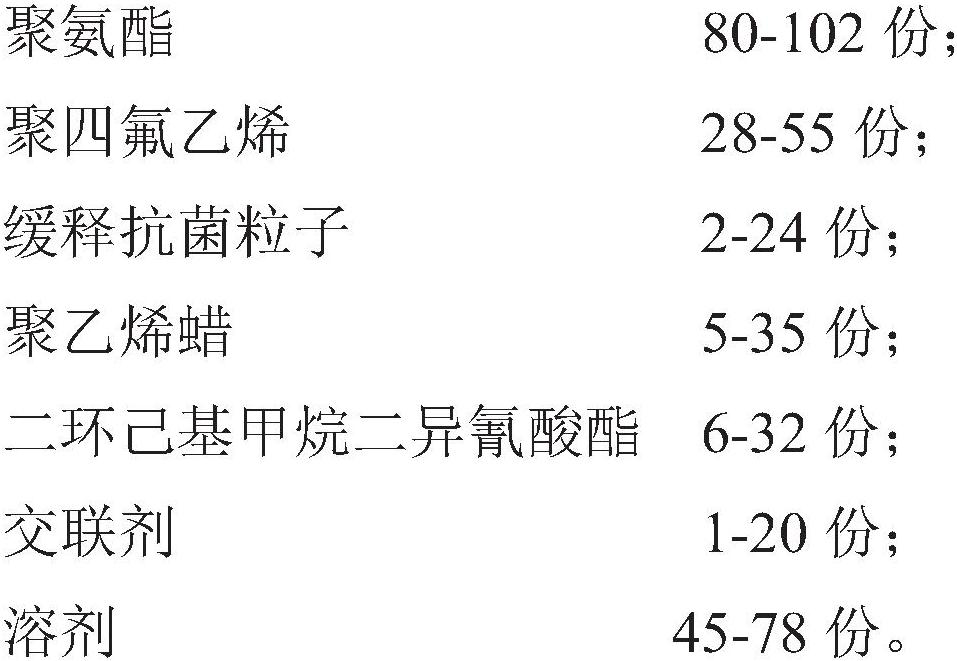

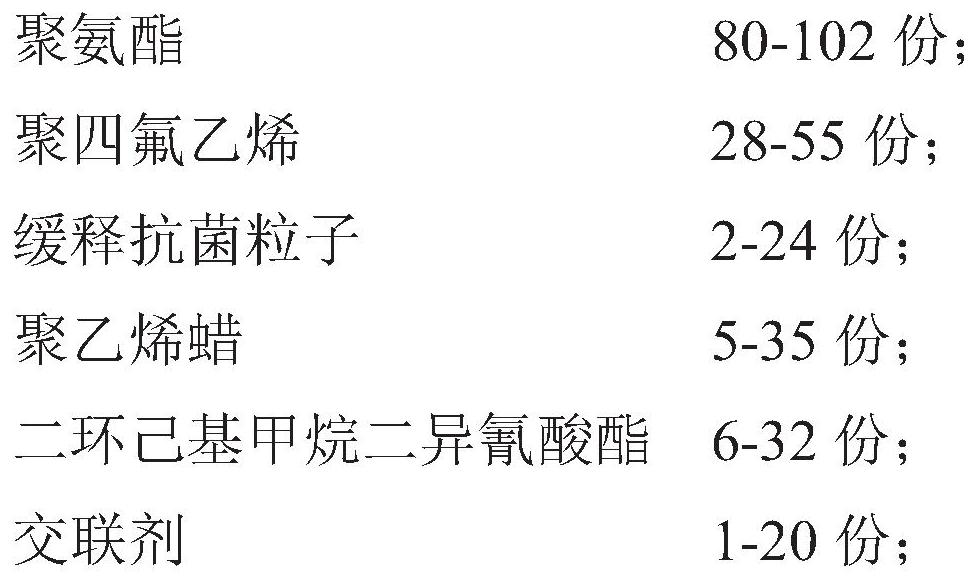

[0077] The film material includes the following components in parts by weight:

[0078]

[0079] Wherein, slow-release antibacterial particles are prepared by the following methods:

[0080] 1) Add ammonia water to the mixed solution of ethanol and deionized water, add dodecylamine and trimethylbenzene to the mixed solution under constant stirring at 50°C, and ultrasonically disperse for 6 minutes; add again under constant stirring at 40°C Tetraethyl orthosilicate, reacted for 4 hours, filt...

Embodiment 2

[0096] An antibacterial dumbbell material and an antibacterial dumbbell, the antibacterial dumbbell material comprising a core material for preparing a dumbbell body and a film material for preparing a film layer coated on the surface of the dumbbell body;

[0097] The core material includes the following components in parts by weight:

[0098]

[0099] Wherein, the resin is a mixture of epoxy resin E20 and polycarbonate, and the mass ratio of epoxy resin and polycarbonate is 7:3.

[0100] The film material includes the following components in parts by weight:

[0101]

[0102] Wherein, the preparation method of slow-release antibacterial particles is the same as that of Example 1. The preparation method of the antibacterial dumbbell is the same as that in Example 1.

Embodiment 3

[0104] An antibacterial dumbbell material and an antibacterial dumbbell, the antibacterial dumbbell material comprising a core material for preparing a dumbbell body and a film material for preparing a film layer coated on the surface of the dumbbell body;

[0105] The core material includes the following components in parts by weight:

[0106]

[0107]

[0108] Wherein, the resin is a mixture of epoxy resin E20 and polycarbonate, and the mass ratio of epoxy resin and polycarbonate is 7:3.

[0109] The film material includes the following components in parts by weight:

[0110]

[0111] Wherein, the preparation method of slow-release antibacterial particles is the same as that of Example 1. The preparation method of the antibacterial dumbbell is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com