Electrode material of carbon black-carbon nanotube mixed filled silica gel and process thereof

A carbon nanotube, mixed filling technology, applied in the direction of carbon silicon compound conductors, circuits, electrical components, etc., can solve the problem of inability to take into account electrical conductivity, flexibility and dimensional stability, reduce the mechanical strength and tensile properties of composite materials, electroosmosis The problem of high threshold value can achieve the effect of low AC impedance, optimized production process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

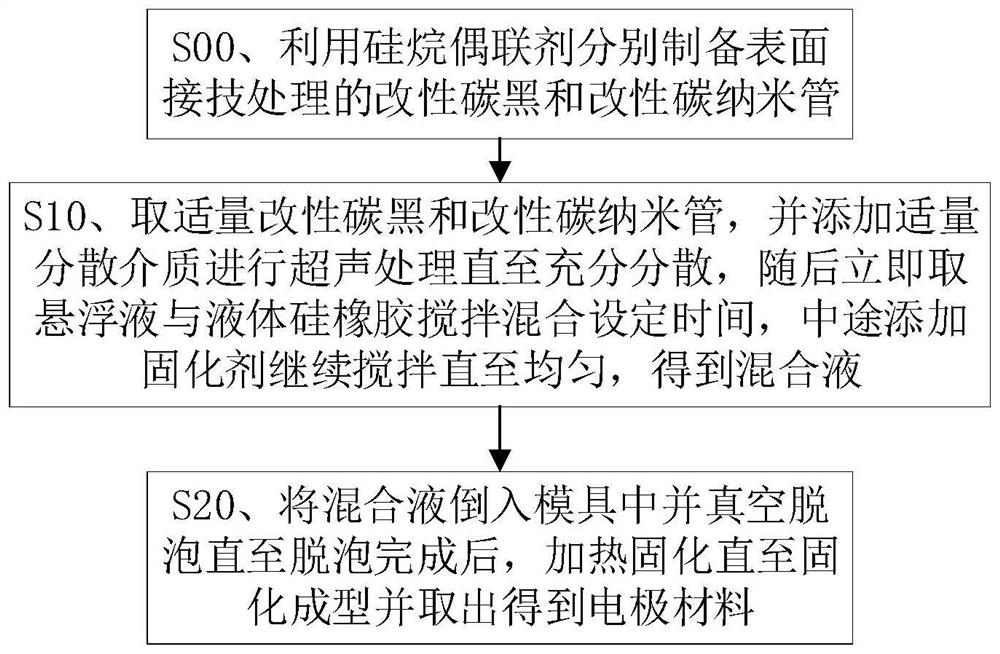

[0042] like figure 1 and Image 6 As shown, this carbon black-carbon nanotube hybrid electrode material filled with silica gel is applied to wearable devices, including the following steps:

[0043] S00, using a silane coupling agent to prepare modified carbon black and modified carbon nanotubes treated by surface grafting respectively;

[0044] Wherein, the weight ratio of carbon black (CB) to the silane coupling agent is 1:10-1:20.

[0045] Wherein, the weight ratio of carbon nanotube (CNT) to silane coupling agent is 1:15-1:30.

[0046] The carbon nanotubes are multi-walled carbon nanotubes produced by chemical vapor deposition.

[0047] Among them, the silane coupling agent is mainly acryloxysilane coupling agent, including but not limited to A-174 (3-methacryloyloxypropyltrimethoxysilane), Z-6033 (3-methacryloyloxypropyltrimethoxysilane) Acyloxypropylmethyldimethoxysilane), A-1597 (3-(trimethoxysilyl)propyl acrylate), M-0725 (3-(trimethoxysilyl)propylmethyl acrylate) ...

Embodiment 2

[0064] Based on Embodiment 1, this embodiment provides a preferred example, and the specific steps are as follows:

[0065] Step 1: Dissolve 1 g of high-conductivity carbon black and 20 g of silane coupling agent A-174 in 200 mL of anhydrous toluene, cover with plastic wrap, ultrasonically treat it in a water bath at 70°C for 1 hour, and then cool to room temperature. To the mixture was added the initiator AIBN 1 g and reacted in an oxygen-free environment in an oil bath at 65°C for 24 hours. After the reaction, the product was naturally cooled and washed with toluene, and then centrifuged by a high-speed centrifuge at a speed of 1400 rpm and a centrifugation time of 10 minutes. Conductive carbon black.

[0066] Step 2: Dissolve 1 g of carbon nanotubes and 30 g of silane coupling agent A-174 in 200 mL of anhydrous toluene, cover with plastic wrap, ultrasonically treat in a 75°C water bath for 1 hour, and then cool to room temperature. To the mixture was added AIBN 1 g and re...

Embodiment 3

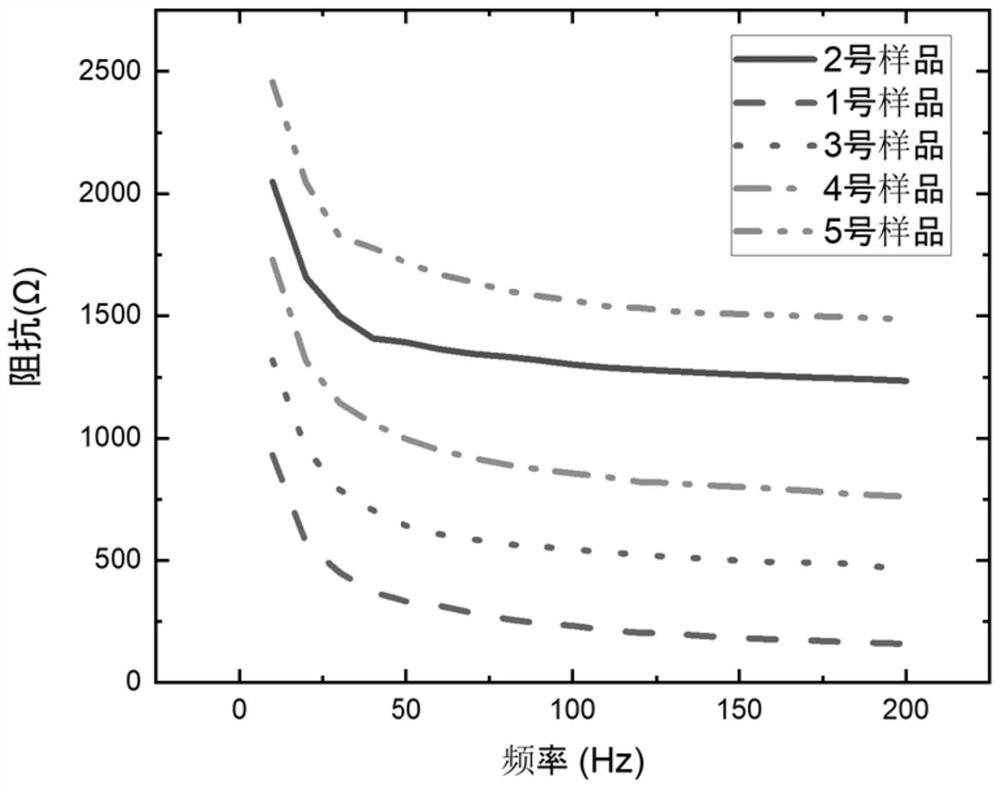

[0070] This implementation is based on Example 1. As a control group, the difference from Example 2 is that: high-conductivity carbon black-carbon nanotubes are not subjected to surface grafting treatment. 1 g of joint agent KH550 was dispersed in an appropriate amount of DMF, followed by mechanical stirring for 5 minutes, ultrasonic dispersion for 30 minutes, and the rest of the operations were the same to obtain No. 2 sample of conductive silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com