Confluence mechanism on beverage back-end secondary packaging line and intelligent control method of confluence mechanism

A technology for secondary packaging and beverages, applied in automatic packaging control, conveyor control devices, packaging, etc., can solve the problems of non-normal operation, affecting the confluence of the confluence mechanism, product congestion, etc., to reduce collision energy, avoid product steering, The effect of avoiding channel congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

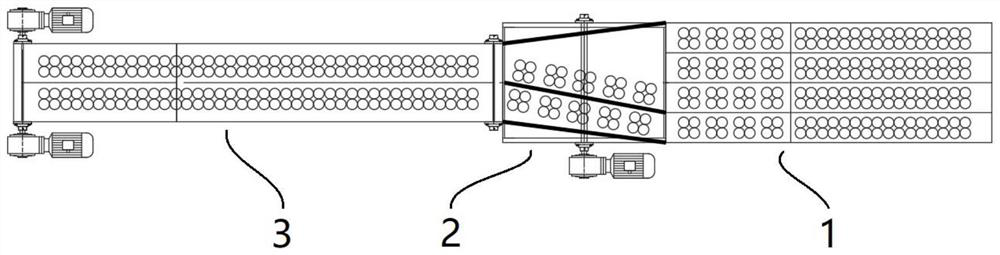

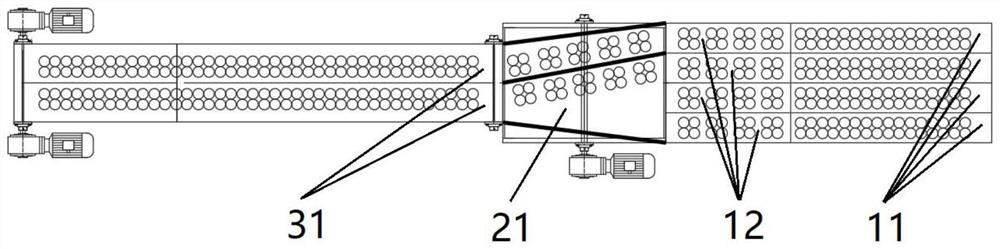

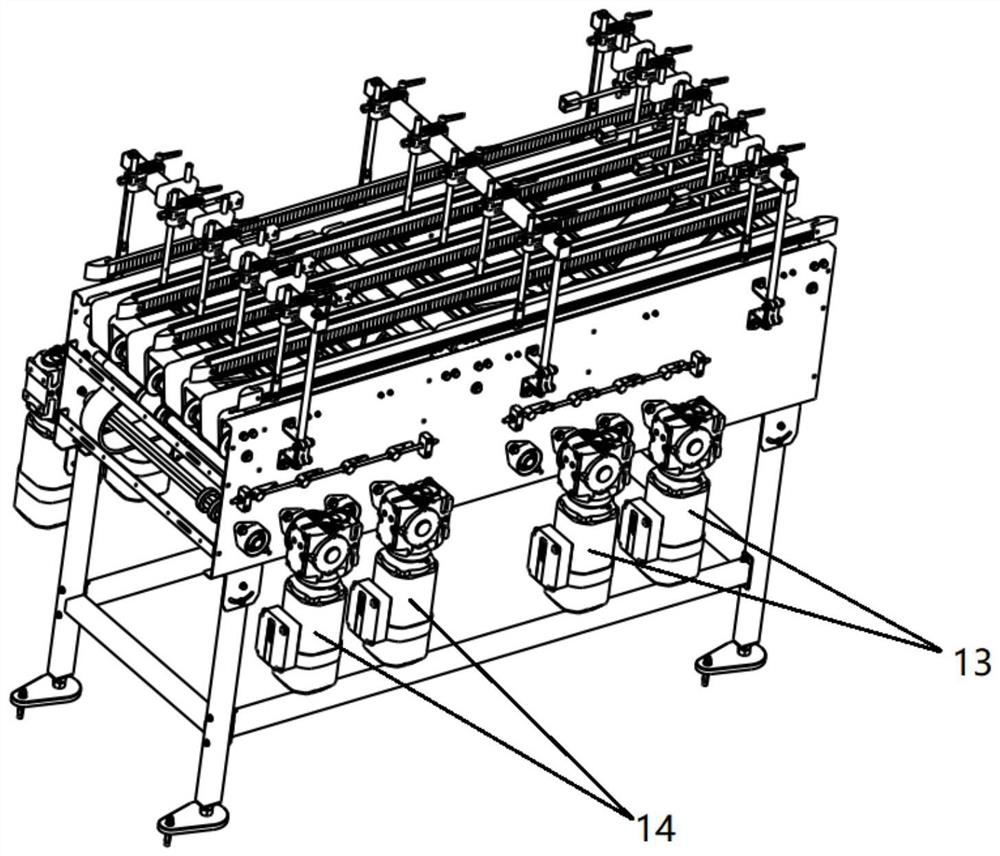

[0056] like Figure 1-9 As shown in the figure, Embodiment 1 provides a confluence mechanism on the secondary packaging line of the beverage rear channel, which is also a four-in-two confluence mechanism, including a four-channel separation conveying mechanism 1, a lane-changing mechanism 2, a dual-channel conveying mechanism 3, The first sensor 4, the second sensor 5, the third sensor 6, the emergency stop switch 7, the alarm 8, the controller 9 (PLC board, microprocessor, etc.) and the rack (the three mechanisms can share a whole rack, They can also be provided with independent racks. The racks play the role of fixing and supporting. The racks are conventional designs and will not be introduced in detail).

[0057] The four-channel separation conveying mechanism 1 includes four parallel channels, and each channel is provided with a first conveyor belt 11 and a second conveyor belt 12 . The first conveyor belt 11 is a low-speed conveyor belt, the second conveyor belt 12 is a...

Embodiment 2

[0065] Embodiment 2 provides an intelligent control method for the confluence mechanism on the secondary packaging line of the beverage rear lane, which is implemented based on the confluence mechanism provided in Embodiment 1, including a lane change control method, a replenishment control method, and a card pack emergency stop alarm. method.

[0066] The lane change control method includes the following steps:

[0067] Step S11, the front end of the lane-changing dial is located between the two lanes on one side, the two second conveyor belts on the side rotate to transport the product forward, and the two second sensors on the side continuously generate and send the second type Electrical signals, the controller receives the second type electrical signals sent by the two second sensors on the side and counts them;

[0068] Step S12, when the count value is equal to the preset number threshold, the controller controls the two second motors on the side to stop rotating; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com