Multi-station fixing device for workpiece machining based on numerical control lathe

A technology of numerical control lathes and fixing devices, which is applied in the field of numerical control lathes, can solve the problems of inconvenient fixing devices, multi-process processing of workpieces that cannot be processed, and inconvenient angle adjustment of workpieces, etc., and achieve the effects of simple angle adjustment, enhanced stability, and simple intermittent adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Please refer to Figure 1 to Figure 11 :

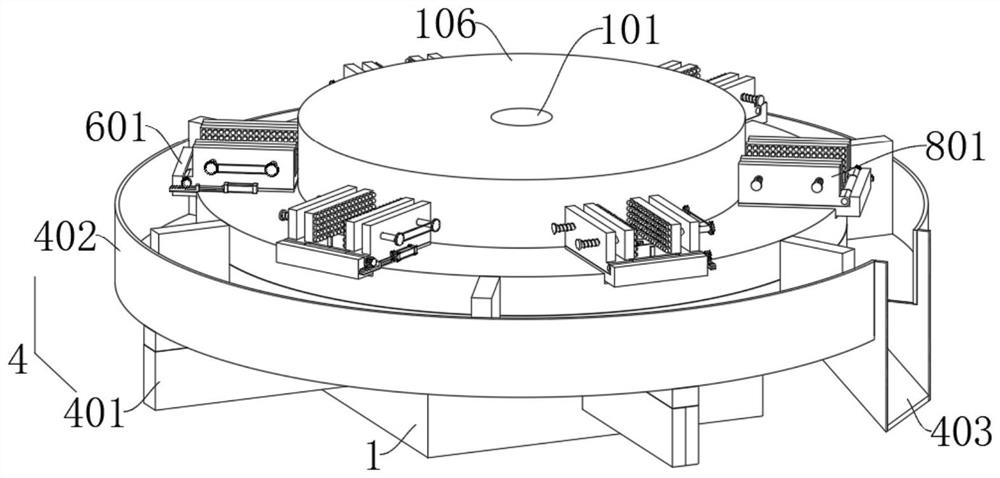

[0047] The invention provides a multi-station fixing device for workpiece processing based on a numerically controlled lathe, comprising: a base 1;

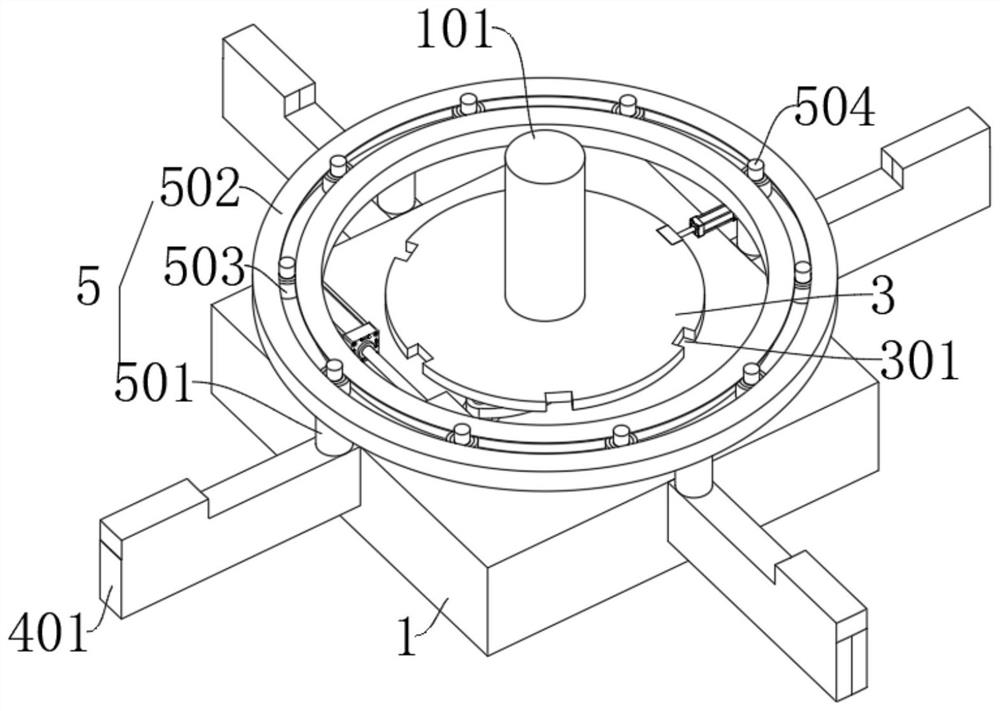

[0048] A bearing is fitted inside the base 1, a support shaft 101 is fitted inside the bearing, and a positioning plate 3 is fixed on the outside of the support shaft 101; the positioning plate 3 is provided with a positioning groove 301, and the positioning grooves 301 are arranged in a circular array; positioning; A positioning block 303 is slidably arranged on the inner side of the groove 301, and the positioning block 303 is fixedly arranged on the top of the cylinder B302; its specific function is: using the positioning groove 301 to cooperate with the positioning block 303 to achieve the effect of fixing the support shaft 101 and the processing table 106; A ratchet wheel 102 is fixed on the outside of the support shaft 101 , a bearing is fitted on the outside of ...

Embodiment 2

[0054] Example 2: Please refer to Figure 12 :

[0055] The connecting mechanism 5 includes: a connecting column 501, a connecting ring 502 and a ball 505; the connecting column 501 is fixedly arranged on the top of the support frame 401, and the connecting column 501 is arranged in a circular array; the connecting ring 502 is fixedly arranged on the top of the connecting column 501; the ball 505 is installed Inside the top side of the connecting ring 502, the balls 505 are arranged in an annular array, and the top of the balls 505 is in contact with the bottom of the processing table 106; its specific function is: by providing the arrayed balls 505, the stability of the processing table 106 is enhanced. effect; it is beneficial to enhance the stability of the fixing device.

Embodiment 3

[0056] Example 3: Please refer to Figure 9 :

[0057] The fixing mechanism 8 includes: a fixing frame 801, a threaded rod 802, a synchronizing wheel 803, a guide rod 804, a splint 805, a sliding rod 806 and a positioning plate 807; the fixing frame 801 is fixedly arranged outside the auxiliary shaft 602, and the main body of the fixing frame 801 is set as C-shaped structure; the threaded rod 802 is set inside the fixing frame 801 through a threaded connection; the synchronizing wheel 803 is fixedly arranged on the outside of the threaded rod 802, and a timing belt is set on the outside of the synchronous wheel 803; the guide rod 804 is slidably arranged inside the fixing frame 801, and The guide rod 804 and the threaded rod 802 are arranged symmetrically; one set of the splint 805 is fixedly arranged on the top of the guide rod 804, and the other set of the splint 805 is fitted with a bearing inside, and the bearing is fitted on the outside of the threaded rod 802; the splint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com