Assembled welding part and machining method thereof

A processing method and welding technology, applied in metal processing equipment, manufacturing tools, edge parts of workpieces, etc., can solve the problems of unsightly welding or welding, cumbersome processes, poor consistency, etc., to solve poor welding and ensure the accuracy of external dimensions. , the effect of increasing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

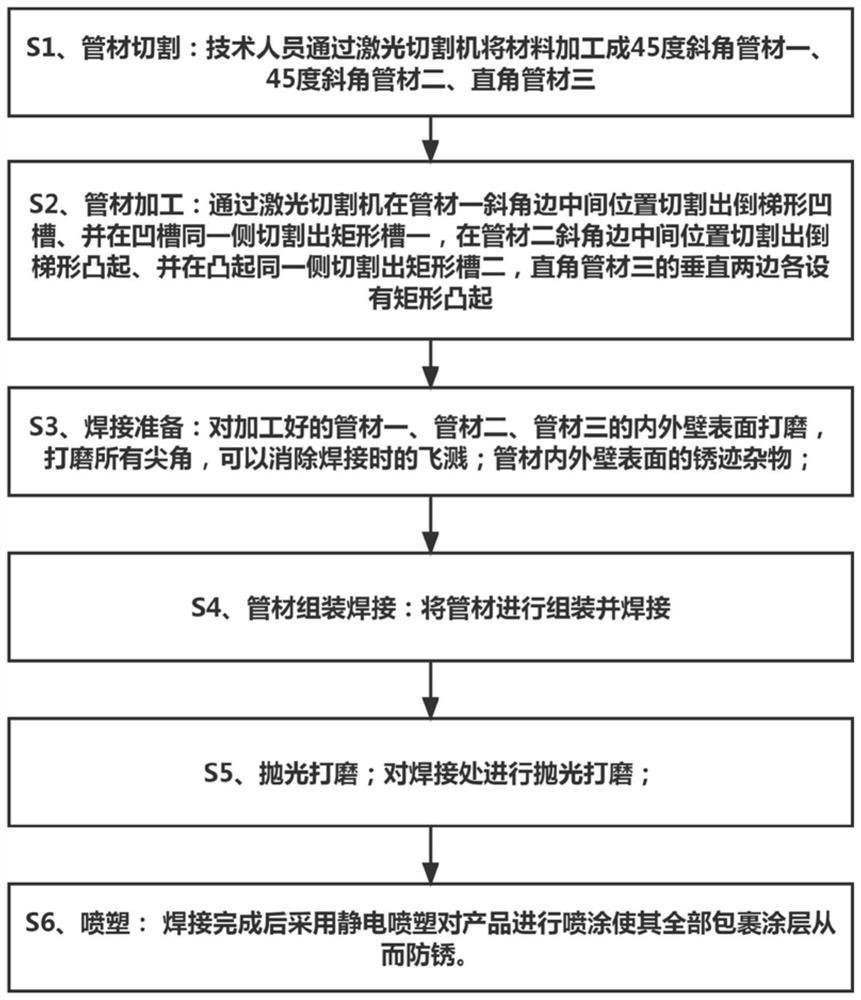

[0038] refer to Figure 1-6 , the invention discloses a processing method of an assembled weldment S1. Pipe cutting: technicians use a laser cutting machine to process the material into a 45-degree bevel pipe 1, a 45-degree bevel pipe 2, and a right-angle pipe 3 3;

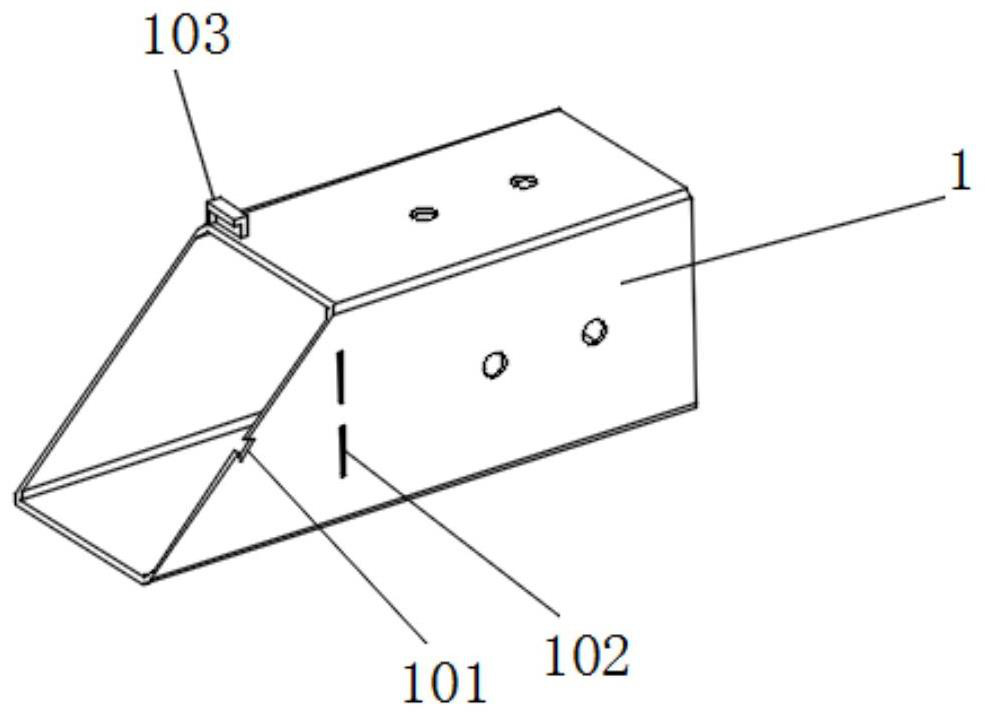

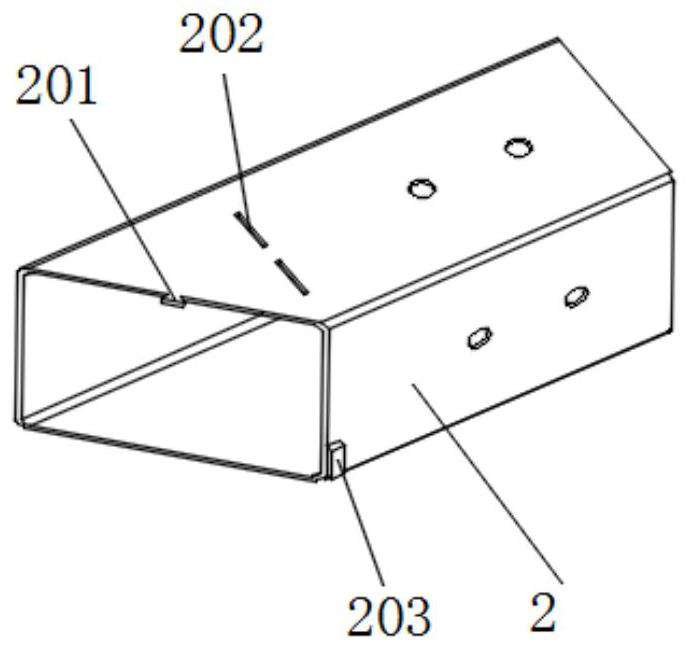

[0039] S2. Pipe material processing: Cut the inverted trapezoidal groove 101 at the middle position of the bevel edge of pipe material one 1 by the laser cutting machine, and cut the rectangular groove one 102 on the same side of the groove, and cut it at the middle position of the pipe material two bevel edge Inverted trapezoidal protrusion 201, and a rectangular groove 202 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com