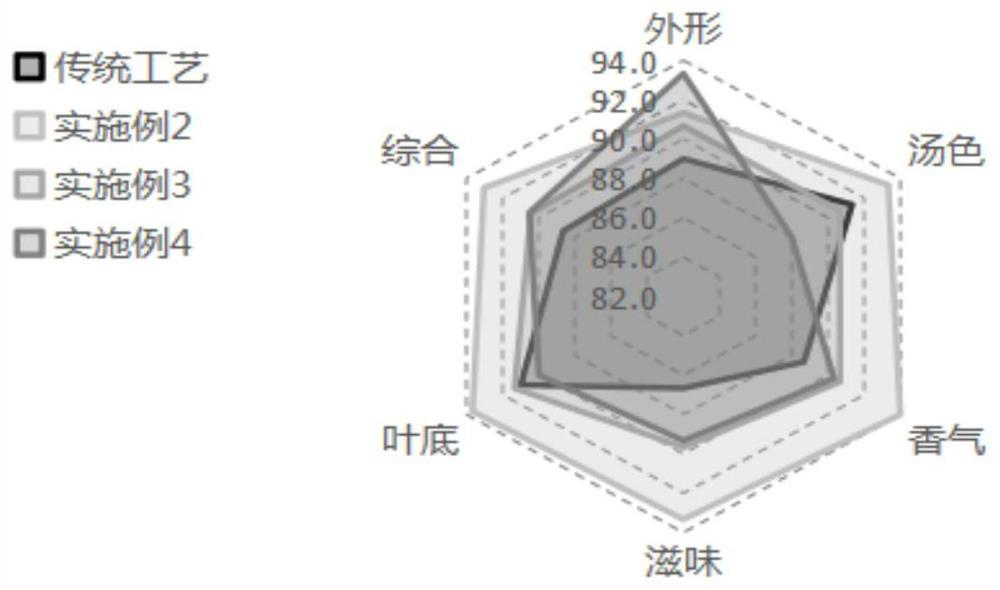

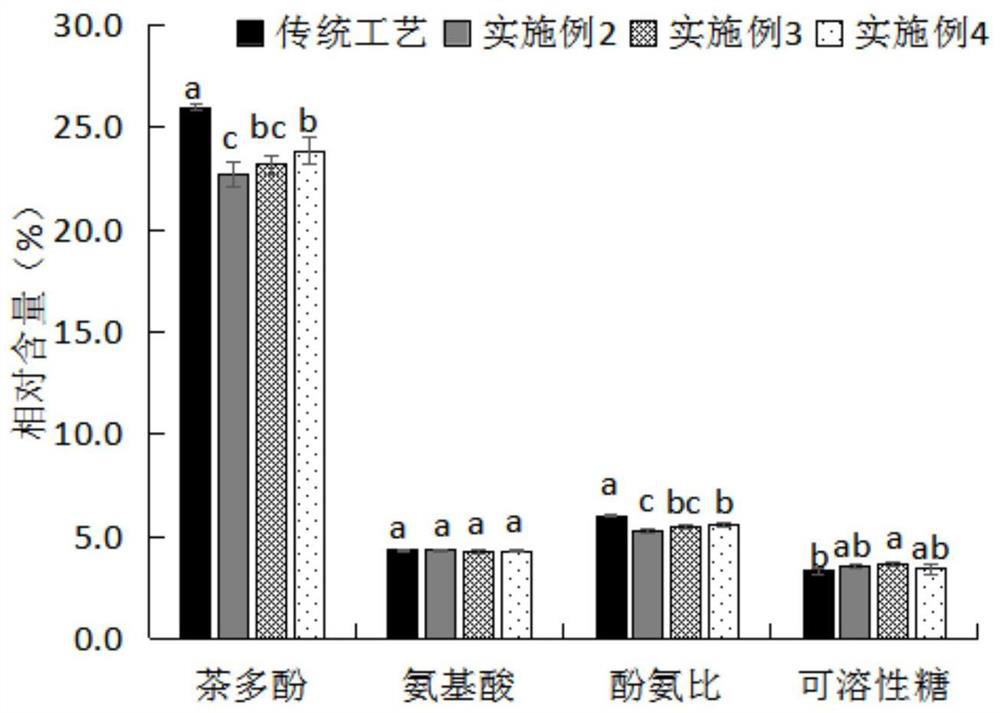

Processing method for reducing astringency and enhancing aroma of summer and autumn green tea

A processing method and technology of green tea, applied in tea treatment before extraction, adaptation to climate change, etc., can solve problems such as watery taste, poor air permeability, difficult temperature control, etc., and achieve increased aroma concentration, reduced bitterness, and strong chestnut aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A processing method of summer and autumn green tea to reduce fragrance, including the following steps:

[0028] Step 1: Preparation of raw materials. In the summer and autumn continuous sunny days, picking medium and small leaf tea trees 1 bud 2 leaf tea fresh leaves as raw materials. The tea tree varieties include Fuding Great White Tea, Bayute morning, Sichuan medium and small leaf groups, etc.;

[0029] Step 2: Raw material maintenance, take air conditioning temperature, control the ambient temperature of 25-28 ° C, 50-60 % humidity, 3-5cm thickness, boiling time 4-6h , Promote the enzymatic hydrolysis of large -molecular substances such as protein and starch, and generate amino acids and soluble sugar that is conducive to improving the quality of tea;

[0030] Step 3: Killing youth treatment, using a drum killing machine, controlling the leaf temperature 75-85 ° C, and taking more slow-down and killing youths. Make full use of hot steam penetration to ensure that fresh ...

Embodiment 2

[0036] A processing method of summer and autumn green tea to reduce fragrance, including the following steps:

[0037] Step 1: Preparation of raw materials, continuous sunny days in autumn, use small and small leaf breeding tea fresh 1 buds and 2 leaves as raw materials. Tea tree varieties include Fuding Great White Tea, Bayutetao, Sichuan medium and small leaf groups, etc.;

[0038] Step 2: Take the air conditioning temperature, control the ambient temperature of 28 ° C, 50 % humidity, 5cm thickness, 6h boiling time, and control the water content of the stalls by 70 %;

[0039] Step 3: Use 60 drums to kill the green leaf to kill the green leaves, control the leaf temperature of 80 ° C, control the amount of leaves of 50kg / h, 3min, and the water content of the blue leaves is 60 %;

[0040] Step 4: Put the killing leaves into the box fermentation machine, control the temperature of 35 ° C, and the air volume is 0.2m 3 / s, the thickness of the leaf layer is 10cm, and the stuffed pil...

Embodiment 3

[0044] A processing method of summer and autumn green tea to reduce fragrance, including the following steps:

[0045] Step 1: In the autumn consecutive sunny day, use small and small leaf breeding tea fresh 1 buds and 2 leaves as raw materials. Tea tree varieties include Fuding Great White Tea, Bayutetao, Sichuan medium and small leaf groups, etc.;

[0046] Step 2: Take the air conditioning temperature, control the ambient temperature of 28 ° C, 55 % humidity, the thickness of the stall 3cm, the spread time of 5h, and the water content of the stall leaves of 70 %;

[0047]Step 3: Use 60 drums to kill the green leaf to kill the green leaves, control the leaf temperature 70 ° C, control the amount of leaves of 55kg / h, 4min, and the water content of the blue leaves is 58 %;

[0048] Step 4: Put the killing leaves into the box fermented pile while it is hot, control the temperature 40 ° C, and the air volume is 0.3m 3 / s, the thickness of the leaf layer is 10cm, and the stuffed pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com