Method and system for monitoring hydrogen leakage amount of stator cooling water of generator

A generator and cold water technology, applied in the direction of water testing, nuclear power generation, greenhouse gas reduction, etc., can solve the problems that cannot be completely eliminated, cannot be monitored in real time and accurately, and cannot be protected from gas removal, etc., to achieve simple composition, The effect of small measurement error and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

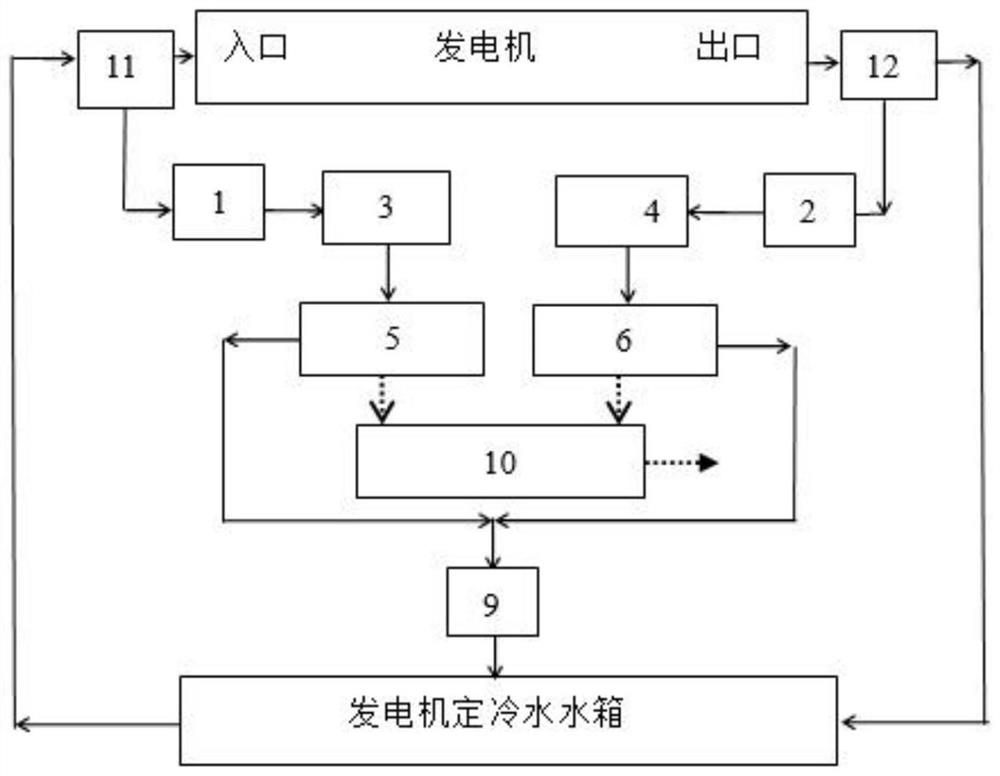

[0046] see figure 1 It is a system of the present invention for directly monitoring the amount of hydrogen leakage of cold water from a generator. The solid line in the figure represents the connection of the water flow pipeline, and the dotted line represents the signal connection. The system includes: fixed cold water inlet water sampling point 11, generator fixed cold water outlet water sample 12, inlet water sampling valve 1, outlet water sampling valve 2, fixed cold water inlet water sample cooler 3, fixed cold water outlet water sample cooler 4, paired An online dissolved hydrogen sensor 5 for monitoring the water sample at the inlet of the fixed cold water, an online dissolved hydrogen sensor 6 for monitoring the water sample at the outlet of the fixed cold water, a confluence funnel 9, and a calculation module 10 for the hydrogen leakage of the fixed cold water. The fixed cold water tank provides cooling circulating water for the generator stator.

[0047] The fixed c...

Embodiment 2

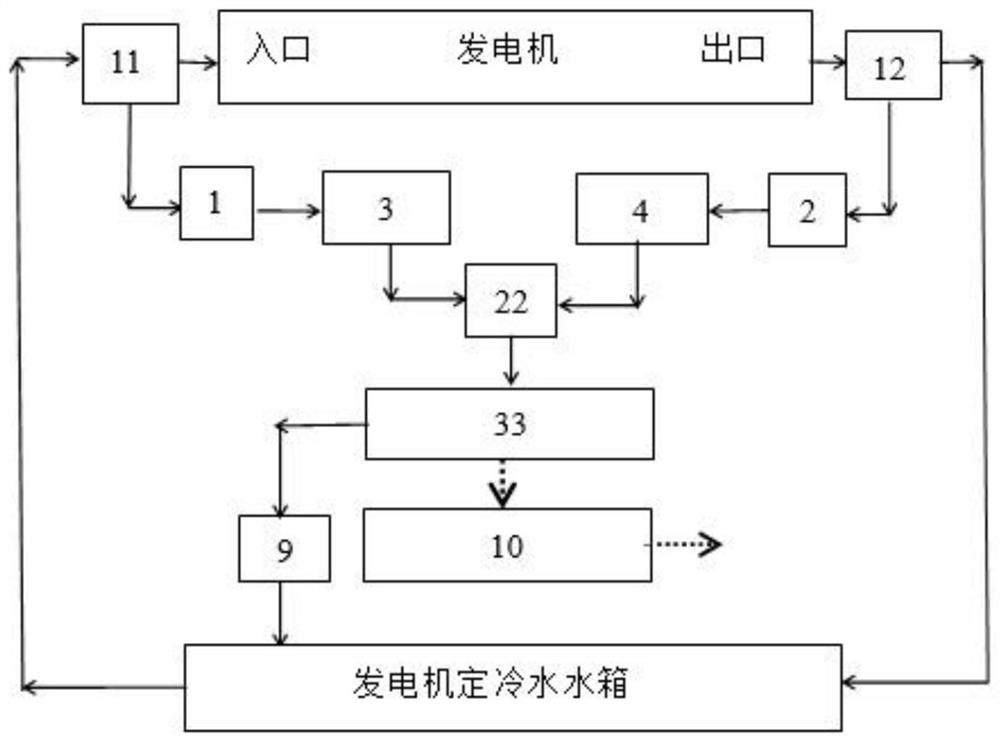

[0058] see figure 2 Embodiment 2 of the present invention is a system for directly monitoring the amount of hydrogen leakage of cold water from a generator. The solid line in the figure represents the connection of the water flow pipeline, and the dotted line represents the signal connection. The difference between Example 2 and Example 1 is that the number of on-line dissolved hydrogen sensors provided is different. In this embodiment, there is only one online dissolved hydrogen sensor 33 and one three-way valve 22 . as the picture shows:

[0059] The fixed cold water inlet water sampling point 11 is connected with the inlet end of the inlet water sampling valve 1 through a pipeline, and the outlet end of the inlet water sampling valve 1 is connected with the inlet of the fixed cold water inlet water sample cooler 3 through a pipeline. The outlet is connected to one end of the three-way valve 22 through a pipeline. The generator constant cold water inlet water sample 12 i...

Embodiment 3

[0063] see image 3 Embodiment 3 of the present invention is a system for directly monitoring the amount of hydrogen leakage of cold water from a generator. The solid line in the figure represents the connection of the water flow pipeline, and the dashed line represents the signal connection. The difference between Embodiment 3 and Embodiment 2 is that the number of three-way valves 22 is two. A three-way valve 22 is respectively provided at the outlet of the constant cold water inlet water sample cooler 3 and the constant cold water outlet water sample cooler 4, and the same on-line dissolved hydrogen sensor 33 is connected through the three-way valve 22. One end of the two three-way valves 22 is also directly or indirectly connected to the generator cooling water tank or the waste water discharge system. The on-line dissolved hydrogen sensor 33 is signally connected to the calculation module 10 for determining the amount of hydrogen leakage of the cooling water. When the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com