Snow density detection method

A density detection and density technology, applied in specific gravity measurement, measurement device, climate sustainability, etc., can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

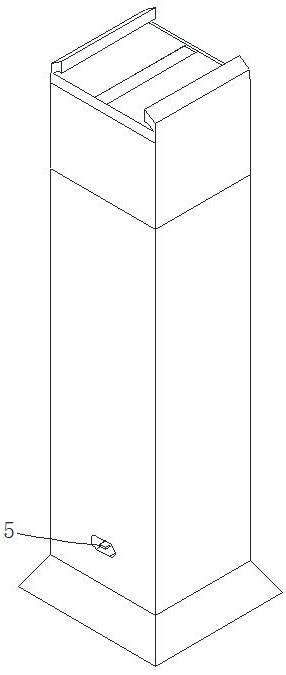

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

[0029] In specific implementation: a snow density detection method, the main point of which is that when detecting the snow density, a predetermined volume of snow is intercepted from top to bottom, heated and melted, and then the weight is detected, and then the weight is divided by the volume to obtain the snow density.

[0030] This is because the snowflakes are in a hexagonal state with extremely large edges, and the detection weight after the container is directly contained is likely to cause a large detection error due to the friction between the container wall and the snowflake. Therefore, the method of detecting the snow weight after heating and melting can be extremely The detection accuracy is greatly improved, and the detection calculation of snow density is ensured to be more accurate.

[0031] Specifically, in this embodiment, when detecting the snow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com